End sensitive fiber bragg grating high-intensity focused ultrasound sensor and system

A fiber Bragg grating and focused ultrasound technology, which is applied in the field of sensing, can solve the problems of high-intensity focused ultrasonic sensor with no end-sensitive fiber Bragg grating, susceptibility to standing wave interference, low spatial resolution, etc., to meet the requirements of MHz ultrasonic Measuring requirements, eliminating the influence of ultrasonic standing waves, and the effect of simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

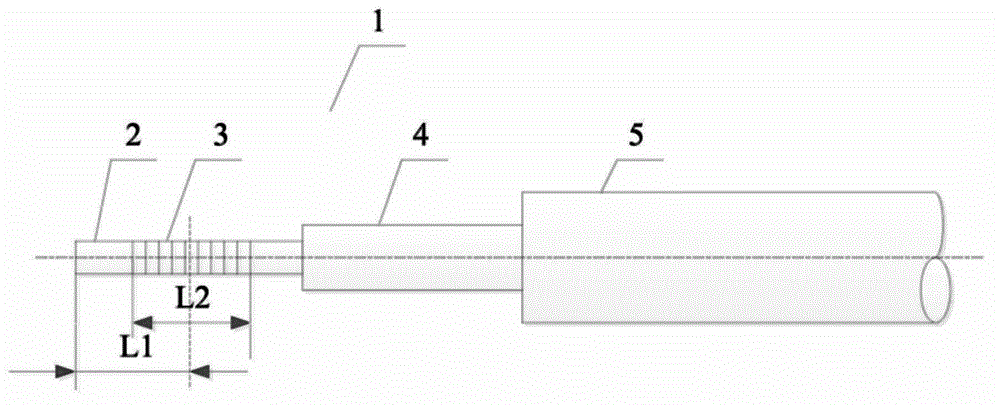

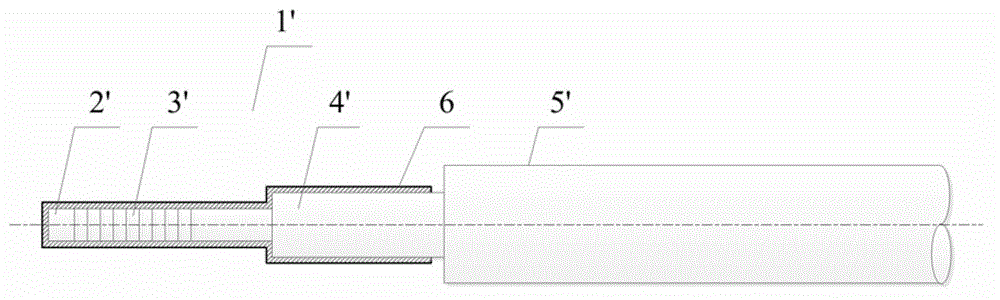

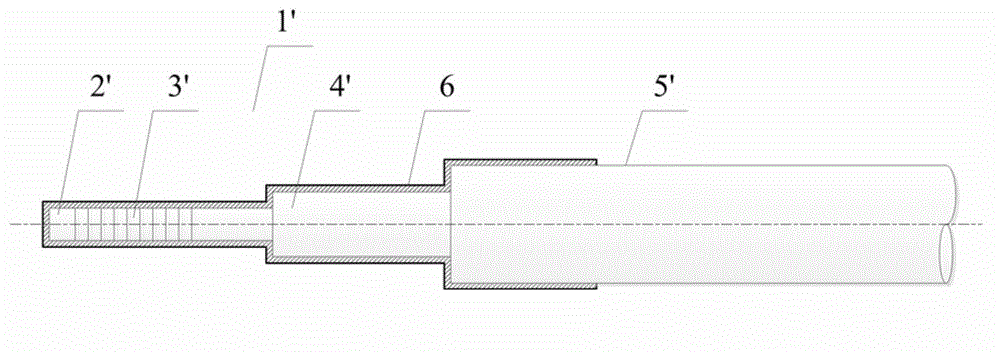

[0029] The end-sensitive fiber Bragg grating high-intensity focused ultrasonic sensor 1 is composed of a single-mode fiber and a fiber Bragg grating on the single-mode fiber, such as figure 1 As shown, there is a fiber grating with a gate length of L2 at the end of the single-mode fiber, and the center position of the fiber grating with a gate length of L2 is located at a position L1 away from the end of the single-mode fiber, and the fiber Bragg grating is a fiber Bragg grating , can also be other types of fiber gratings; that is, a grating with a length of L2 is written at one end of the single-mode optical fiber at a distance from the end L1 to form an end-sensitive fiber grating high-intensity focused ultrasonic sensor; or the length of the grid is One end of the fiber grating single-mode fiber of L2 is cut off to form an end-sensitive fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com