Positive pressure leak hole calibration method

A positive pressure leak and leak technology, which is applied in the direction of detecting the appearance of fluid at the leak point, using the liquid/vacuum degree for liquid tightness measurement, etc. The problems of high technical content of calibration and calibration devices are solved, so as to achieve the effect of saving accumulation time, simple and easy calibration process, and short calibration time period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

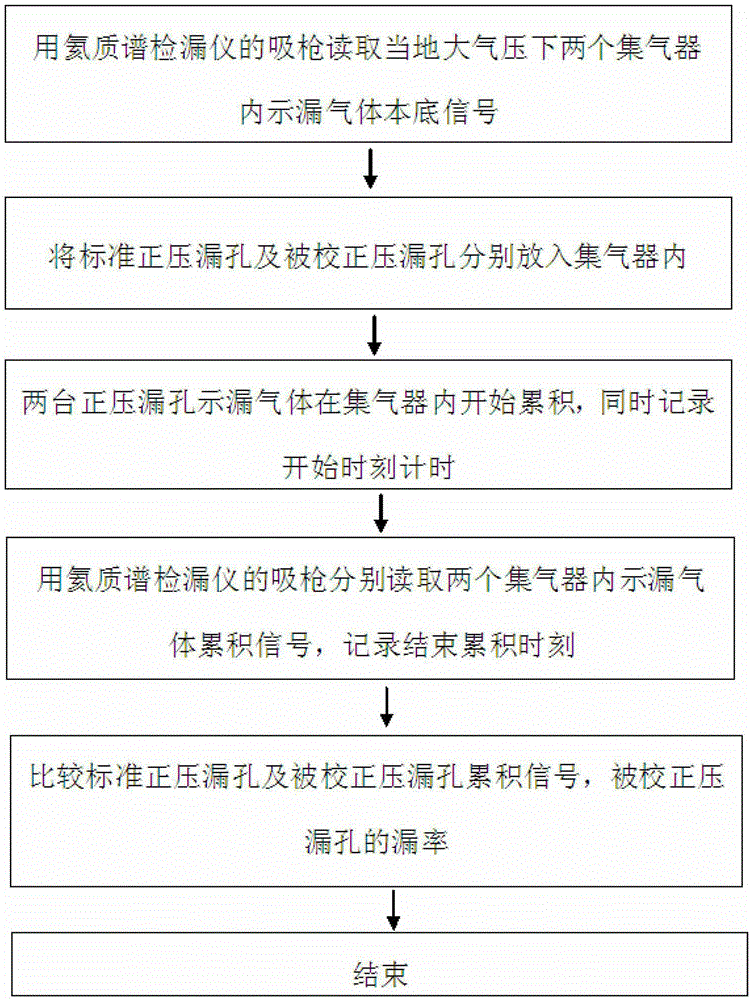

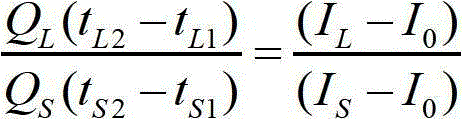

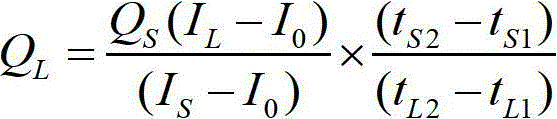

[0025] Such as figure 1 As shown, a method for calibrating a positive pressure leak, the steps of the method are as follows:

[0026] Step 1. Preheat the helium mass spectrometer leak detector for 3 hours, respectively introduce local air into the two gas collectors, and then close the two gas collectors;

[0027] Step 2. Insert the sniffer gun of the helium mass spectrometer leak detector into any gas collector, and read the background signal I of the leaking gas helium in the gas collector under the local atmospheric pressure through the helium mass spectrometer leak detector. 0 =1.05×10 -7 Pa.m 3 / s;

[0028] Step 3. Put the standard positive pressure leak and the calibrated pressure leak into two gas collectors respectively; wherein, the standard positive pressure leak and the calibrated pressure leak are of the same type, and the standard positive pressure leak is of the same type. The leak rate is known, but the leak rate of the calibrated leakage hole is unknown;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com