Non-plug-in water content sensor of culture substrate

The technology of cultivation substrate and sensor is applied in the field of two-point calibration device, which can solve the problems of difficult quantitative preparation of saturated wet soil, inconvenient operation, and lack of adaptability, and achieves a simple two-point calibration model method with low cost and convenient calibration process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] The present invention aims at the above-mentioned deficiencies of the existing soil water content sensors, and aims at the different physical and chemical properties of the cultivation substrate relative to the soil, and proposes a non-insertable cultivation substrate moisture sensor with simple production, low cost, and one-sided sensitivity, and provides A calibration model of this type of sensor is proposed, and a simple two-point calibration method is provided.

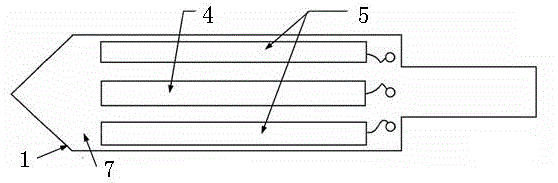

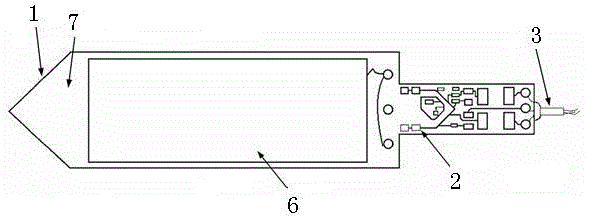

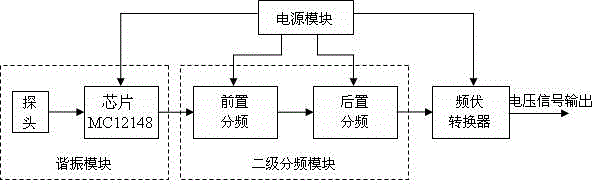

[0028] In order to achieve the above object, the present invention discloses a non-insertable cultivation substrate water content sensor and its calibration method, including a single-side sensitive capacitive probe made by printed circuit board (PCB) technology for sensitive cultivation substrate moisture content; Based on the resonance principle, a capacitance measurement circuit with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com