Spring salt mist fatigue test device

A fatigue test and fatigue testing machine technology, applied in the field of spring salt spray fatigue test device, can solve problems such as spring corrosion, influence on the structural strength of the spring itself, and influence on the service life of the spring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

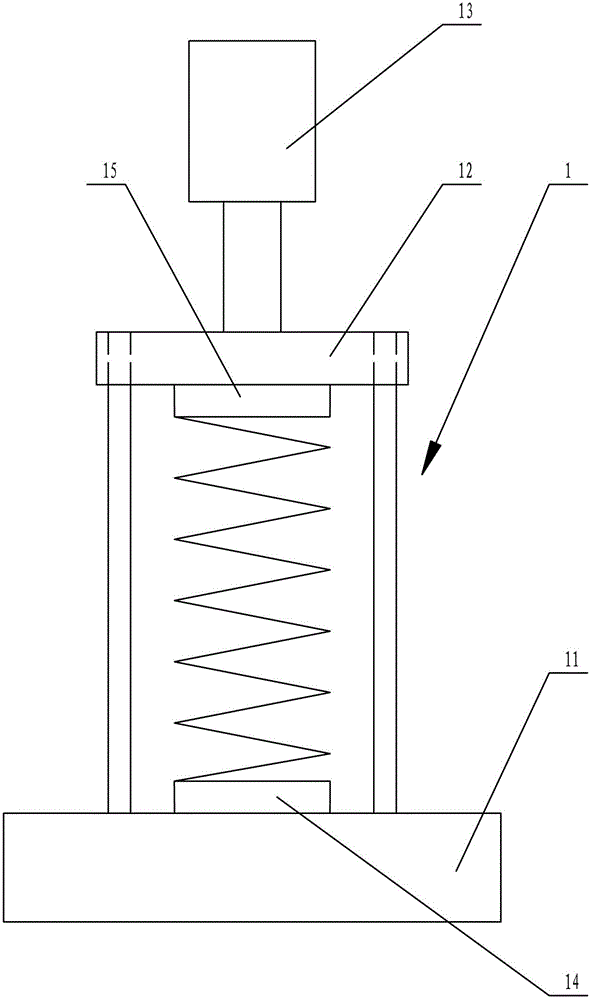

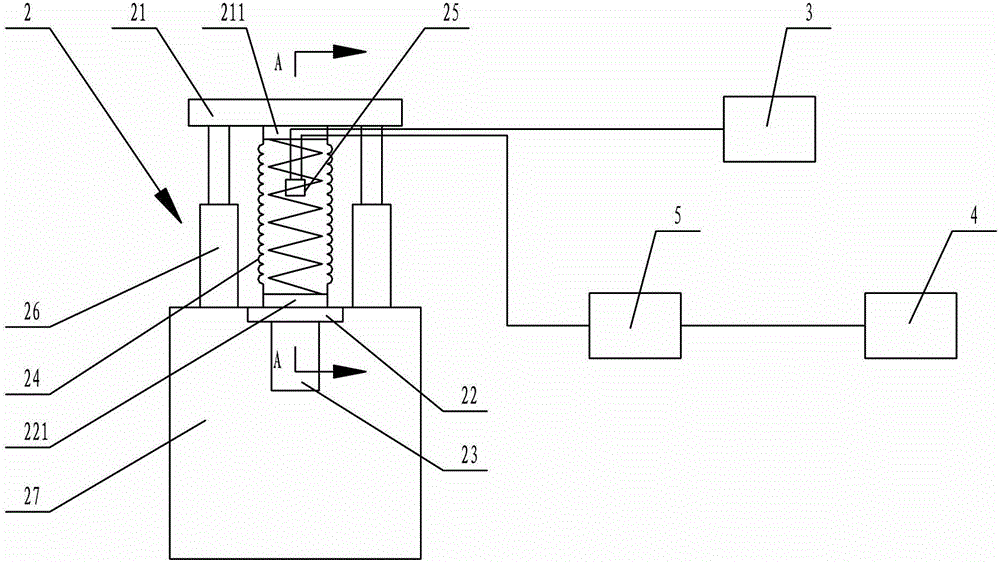

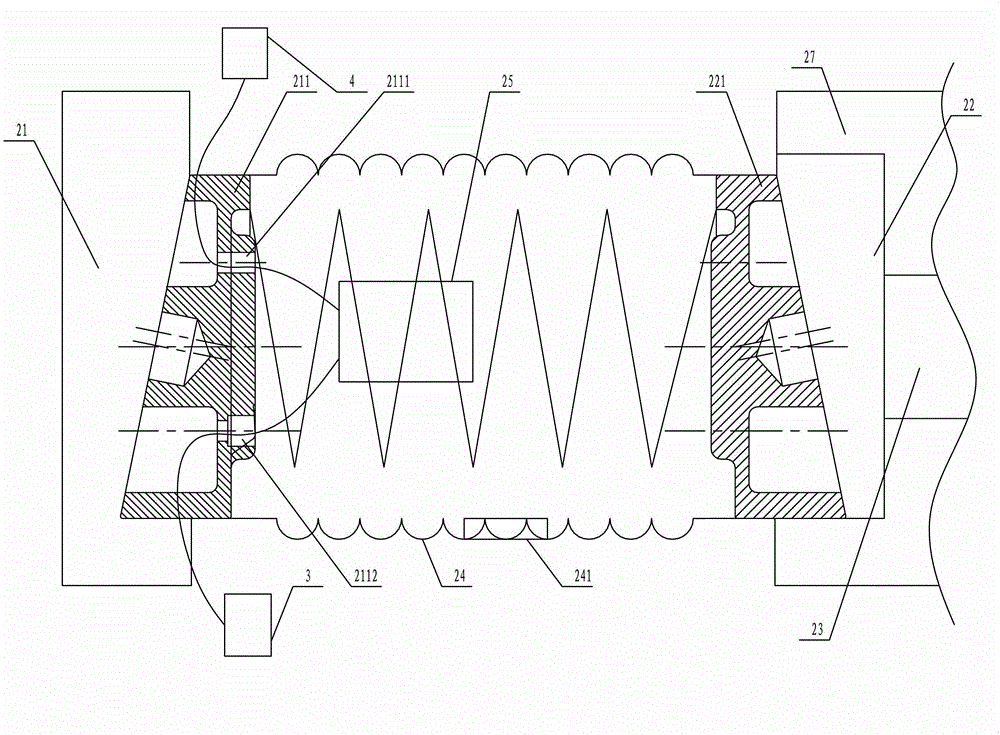

[0048] like figure 2 and image 3 As shown, the spring salt spray fatigue test device provided by Embodiment 1 of the present invention includes a spring fatigue test machine, and the spring fatigue test machine includes a test mechanism 2, and the test mechanism 2 also includes a sleeve 24 and a salt spray device 25, and the sleeve One end of 24 is sleeved on the first spring seat 211 of the test mechanism 2, the other end of the sleeve 24 is sleeved on the second spring seat 221 of the test mechanism 2, and the salt spray device 25 is arranged in the sleeve 24. The mist spray device 25 includes a water spray port 251 and an air spray port 252. The water spray port 251 is connected to the brine tank 3 through a pipeline, and the air spray port 252 is connected to the air source device 4 through a pipeline.

[0049] During use, first the test spring is fixed on the spring fatigue testing machine, wherein one end of the spring is fixed on the first spring seat 211, the other ...

Embodiment 2

[0066] In order to effectively improve the test efficiency of the spring salt spray fatigue test device, multiple sets of test mechanisms 2 can be set in the salt spray fatigue test device.

[0067] like Figure 4 As shown, the spring salt spray fatigue test device provided by Embodiment 2 of the present invention includes a spring fatigue test machine, and the spring fatigue test machine includes four sets of test mechanisms 2, wherein each set of test mechanism 2 also includes a casing 24 and a salt spray spray device 25, one end of the sleeve 24 is sleeved on the first spring seat 211 of the test mechanism 2, the other end of the sleeve 24 is sleeved on the second spring seat 221 of the test mechanism 2, and the salt spray device 25 is set on the sleeve Inside the pipe 24, the salt mist spray device 25 includes a water injection port 251 and an air injection port 252. The water injection port 251 is connected to the brine tank 3 through a pipeline, and the air injection por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com