A drilling fluid analysis device and analysis method thereof

An analysis device and analysis method technology, applied in the direction of material excitation analysis, Raman scattering, etc., can solve the problems affecting the stability and reliability of gas chromatographic analysis, complex gas circuit system of gas chromatographic analysis equipment, high failure rate, etc., to achieve The effect of high accuracy, low cost, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

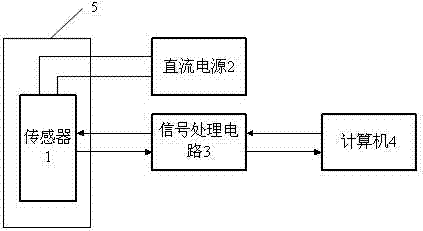

[0034] See attached figure 2 As shown, a drilling fluid analysis device of the present invention includes: a sensor 1 , a DC power supply 2 , a signal processing circuit 3 , and a computer 4 . The DC power supply 2 is connected with the sensor 1 to provide working power; the signal processing circuit 3 is connected with the sensor 1 and the computer 4 respectively; the sensor 1 outputs an analog electrical signal and sends it to the signal processing circuit 3, and the signal processing circuit 3 simulates the analog electrical signal The digital conversion makes it into a Raman digital signal and sends it to the computer 4. The computer 4 processes the received Raman digital signal, and bidirectionally transmits the control signal and data through the signal processing circuit 3 and the sensor 1.

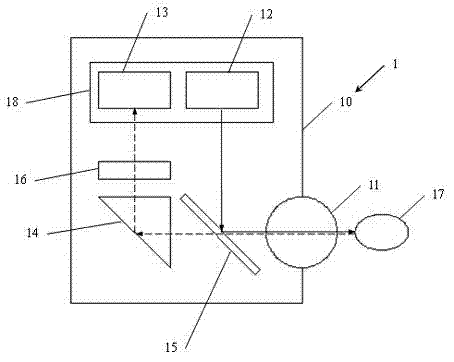

[0035] The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com