A method and system for continuously monitoring the state of a spent fuel pool

A spent fuel pool and monitoring system technology, applied in the field of continuous monitoring of spent fuel pool status, can solve the problems of many mechanical parts, easy failure, maintenance and online calibration difficulties, meet the requirements of insulation and radiation resistance, and solve the problem of equipment The effect of difficult adjustment and convenient online adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

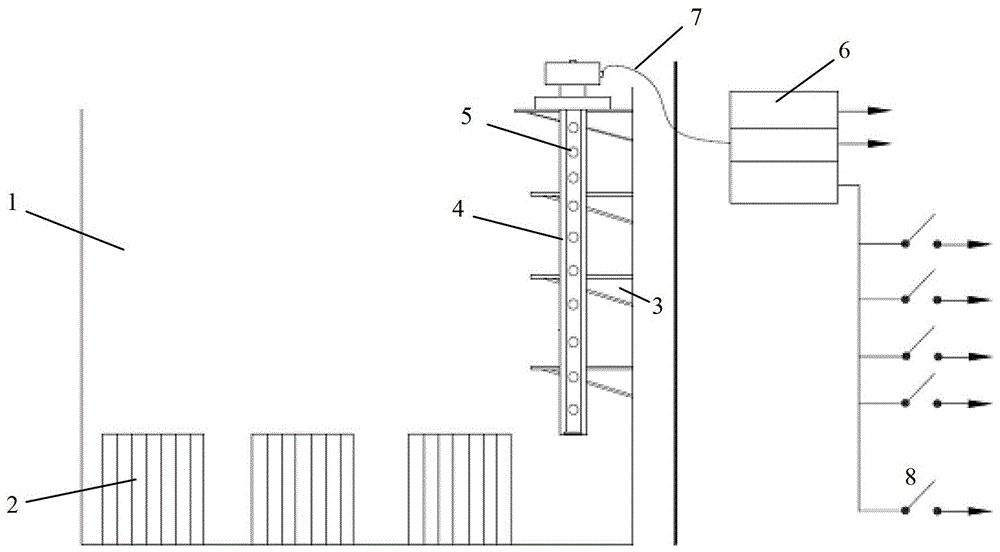

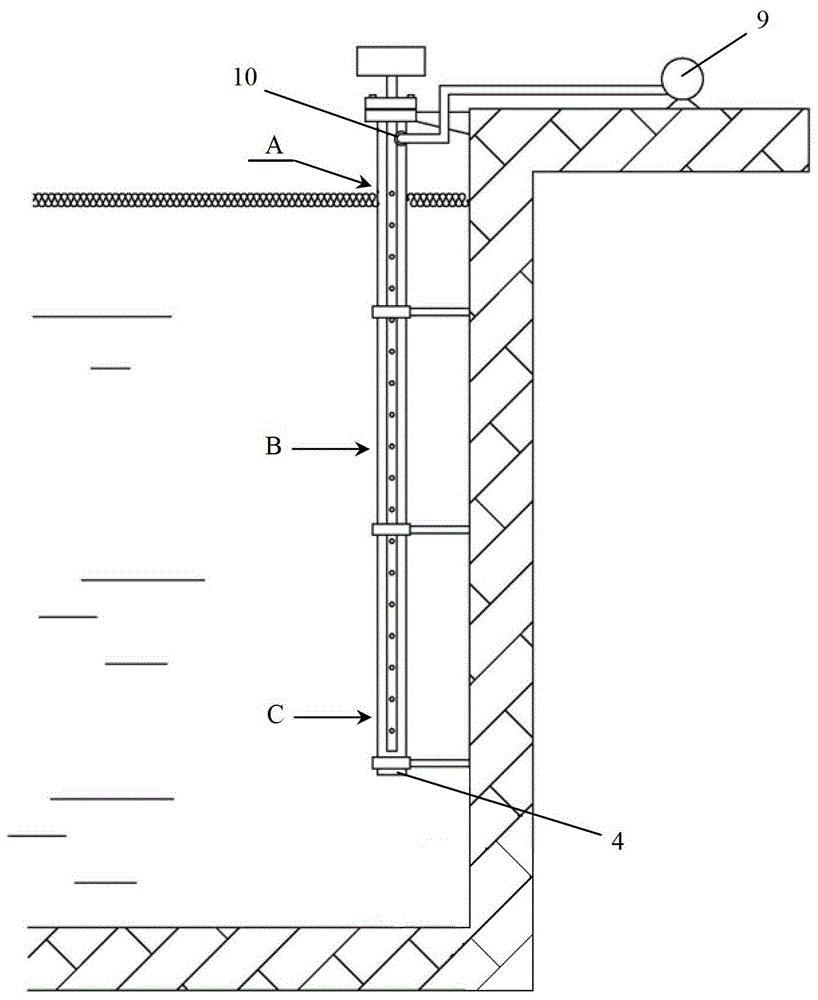

[0019] Such as figure 1 As shown, the spent fuel pool status continuous monitoring system includes a mounting bracket 3 fixedly connected to the side wall of the spent fuel pool 1. A guide cylinder 4 is vertically arranged on the mounting bracket 3. The length of the guide cylinder 4 covers at least the top of the fuel grid 2. The height range to the full water level of the pool. The continuous liquid level sensor 5 with a length of about 9 m is installed in the guide cylinder 4 in a hanging type, and the RTD temperature sensor is installed on the bottom of the guide cylinder 4, and the lower end of the guide cylinder is opened, and the water in the pool enters the guide cylinder from the lower end of the guide cylinder. The embedded part of the side wall of the exhaust tank is fixed by welding the mounting bracket 3, and the top of the continuous liquid level sensor 5 is fixed on the first mounting plate of the mounting bracket 3 through the flange, and can be pulled out from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com