Low-noise low-heat water cooling electric reactor

A reactor and hot water technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of peripheral devices affecting the overall life, insufficient safety performance, and high use noise, and achieves reduced heat generation, good cooling effect, and small heat radiation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

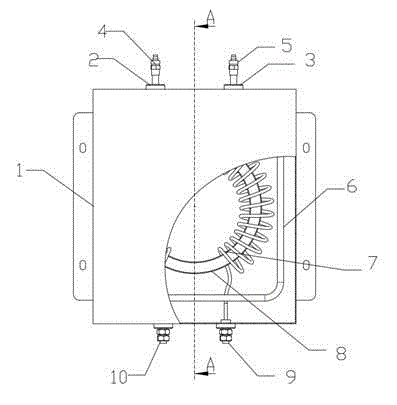

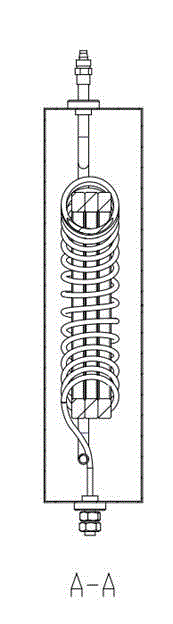

[0011] like figure 1 , 2 The shown low-noise and low-water-cooled reactor includes a shell 1, a cooling pipe, a wire 7, and a magnetically permeable core 8. The cooling pipe includes a left cooling water pipe joint 4, a left insulating sheath 2, and a cooling pipe connected in sequence. Pipeline 6, right insulating sheath 3, right cooling water pipe joint 5, the left cooling water pipe joint 4 is installed on the shell 1 through the left insulating sheath 2, and the right cooling water pipe joint 5 is installed on the right insulating sheath 3 On the casing 1; the wire 7 is wound on the magnetically permeable core 8, fixed on the casing 1 through its own left terminal 10 and right terminal 9, and the inside of the casing 1 is potted with insulating resin.

[0012] Further, the cooling pipe adopts a copper hollow pipe and surrounds the wire 7 in a ring shape.

[0013] Compared with general reactors, it has small size, low heat generation, good cooling effect of cooling water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com