A semiconductor module structure and a method for connecting and fixing bonding wires in the structure

A technology of module structure and bonding wire, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as shortening the service life of modules, breakage of bonding feet, module failure, etc., and achieve the elimination cycle Vibration, prolong service life, and ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

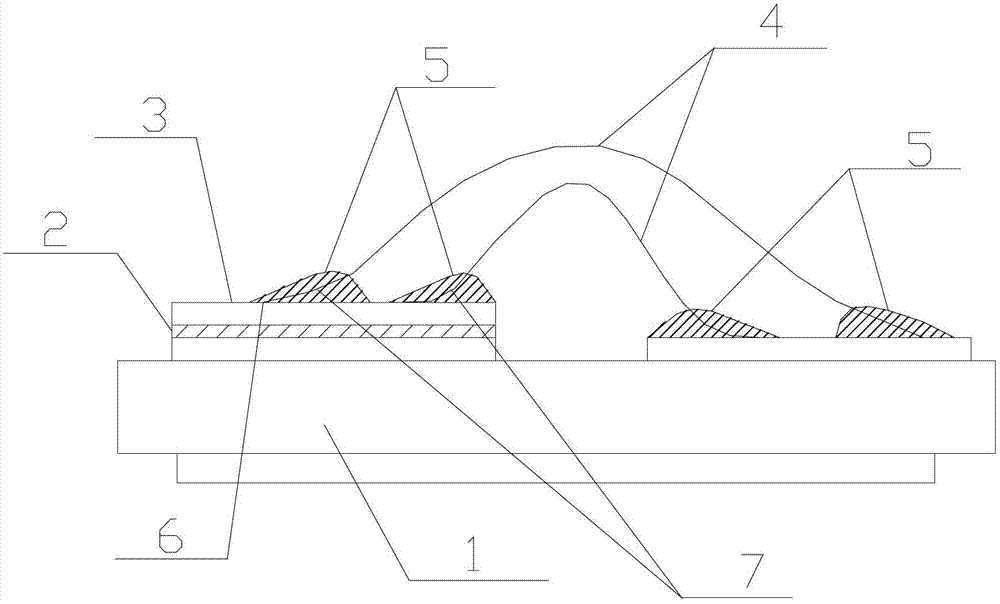

[0035] The height of the glue point 3 formed by the accumulation of the elastic glue at the bottom of the bonding foot 6 and the arc is 1mm, and the shape of the accumulation is not limited.

[0036] The stacking height of glue dots is relatively small, on the one hand, it can reduce the amount of elastic colloid used, on the other hand, it can avoid the impact of excessive accumulation of elastic colloid on other properties of the semiconductor module and affect the use of the semiconductor module.

Embodiment 2

[0038] The rest is the same as that of Example 1, except that the height of the glue point formed by the accumulation of the elastic colloid on the bonding foot and the bottom of the arc is 5mm, and the shape of the accumulation is not limited.

[0039] The stacking height of the glue point is relatively high, which can improve the elastic properties of the elastic colloid, ensure the connection effectiveness of the bonding foot and the bottom of the arc, avoid the breakage of the bonding foot and the starting point of the arc, and ensure the effectiveness of the semiconductor module. The service life of the semiconductor module is reduced, and the cost of use is reduced.

Embodiment 3

[0041] The rest is the same as that of Example 1, except that the height of the glue dot formed by the accumulation of the elastic colloid on the bonding foot and the bottom of the arc is 3 mm, and the shape of the accumulation is not limited.

[0042] The stacking height of the glue point is relatively high, which can improve the elastic properties of the elastic colloid, ensure the effectiveness of the connection between the bonding pin and the bottom of the arc, avoid breakage, ensure the effectiveness of the semiconductor module, improve the service life of the semiconductor module, and reduce the use of cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com