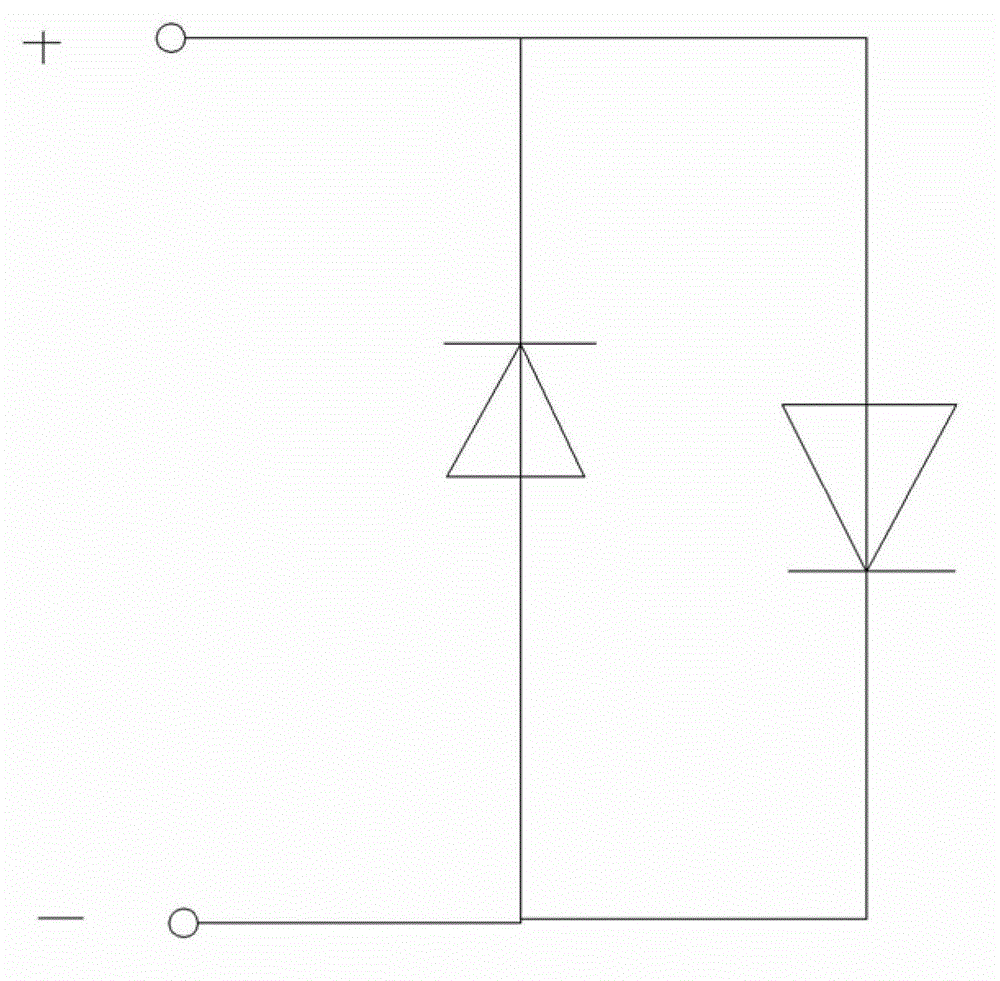

Structure of light-emitting diode structure for improving electrostatic protection and manufacturing method of same

A technology for light-emitting diodes and electrostatic protection, which is applied to circuits, electrical components, and electric solid-state devices. The effect of electrostatic protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

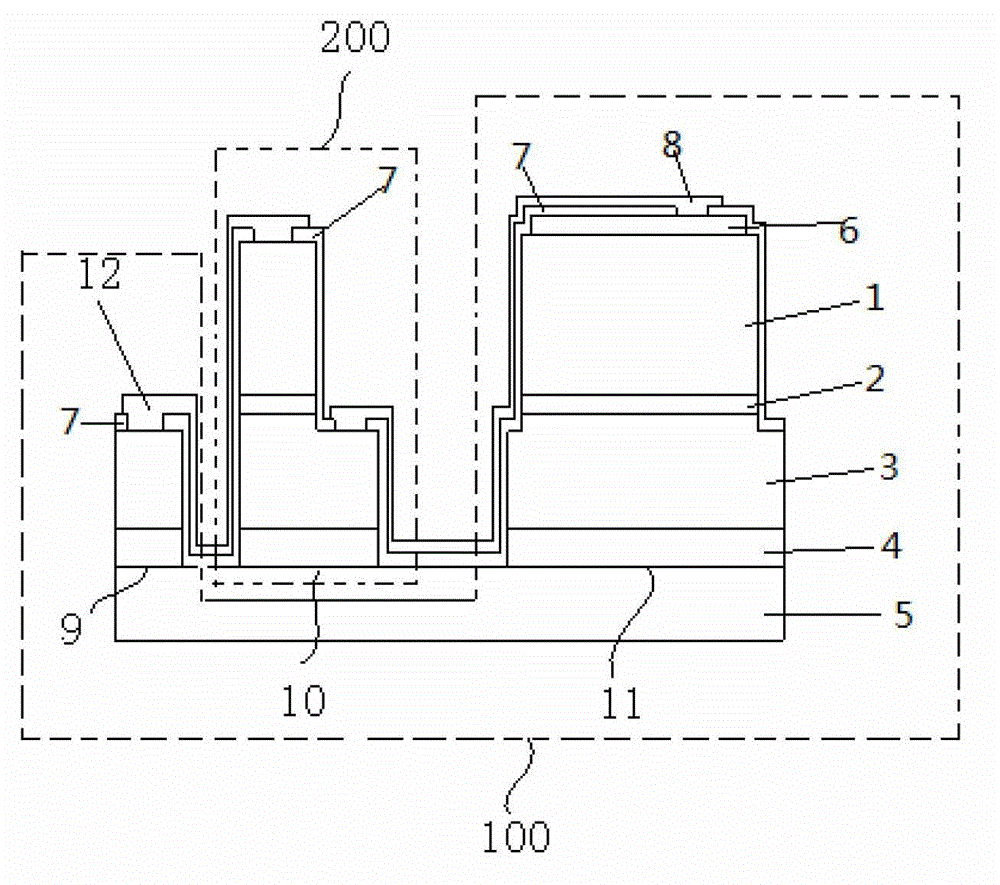

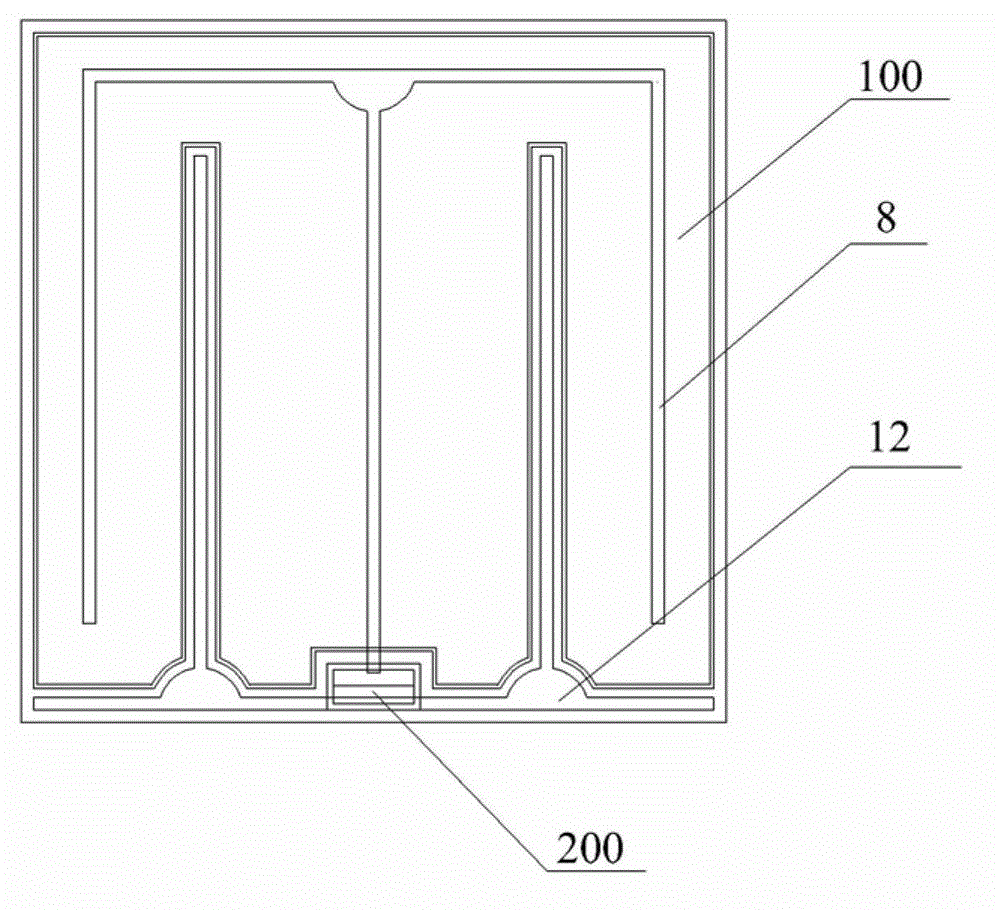

[0038] The present invention will be further described below in conjunction with specific drawings.

[0039] Such as Figure 2~Figure 13 Shown: the present invention includes a P-type semiconductor layer 1, an active layer 2, an N-type semiconductor layer 3, a buffer layer 4, a substrate 5, a transparent conductive layer 6, a passivation layer 7, a first electrode 8, and a first island-shaped Structure 9 , second island structure 10 , third island structure 11 , second electrode 12 , primary diode 100 , secondary diode 200 .

[0040] Such as figure 2 As shown, the present invention includes a substrate 5, on which a buffer layer 4 and an N-type semiconductor layer 3 are sequentially arranged, the buffer layer 4 covers the substrate 5, and the N-type semiconductor layer 3 covers the buffer layer 4, and, The N-type semiconductor layer 3 and the buffer layer 4 are divided into a first island structure 9, a second island structure 10 and a third island structure 11; in the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com