White light source based on laser, optical fiber and light-emitting component, and light-emitting component manufacturing method

A technology of white light source and light-emitting part, which is applied to optical elements, electric light sources, lighting and heating equipment used to change the spectral characteristics of emitted light, etc. Limit LED chip heat, inconvenience linear light source and other issues, to achieve the effect of improving luminous efficiency, reducing loss, and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

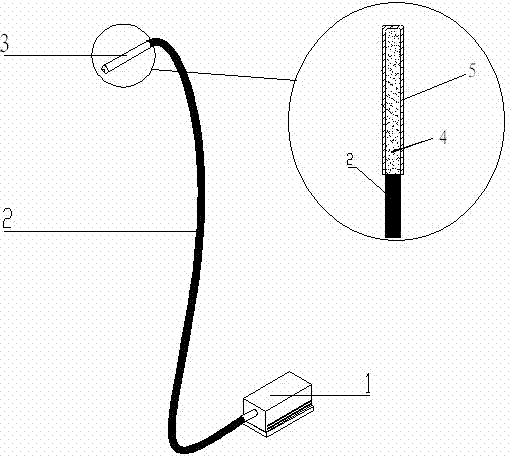

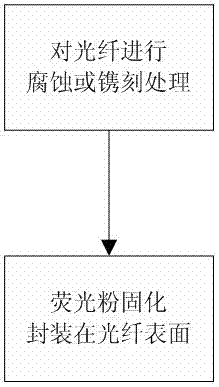

[0027] A method for preparing a light-emitting part, which includes a light-leaking optical fiber used to make the light-emitting part, the preparation method being:

[0028] 1) The light-leakage fiber is chemically corroded by hydrofluoric acid, so that the laser transmitted in the light-leakage fiber can leak out from the corroded place; the method of corrosion treatment is to vertically intrude a certain length of fiber into a certain concentration of strong alkali or strong acid to obtain Use the pulling method to slowly lift the optical fiber at a certain speed. The roughness of different parts of the optical fiber will be different depending on the soaking time of the optical fiber in the solution. By controlling the process, the laser can leak from the side of the corroded optical fiber with a certain intensity distribution. The part of the fiber that is corroded is defined as the light-leakage fiber, and the part of the fiber that is not corroded is defined as the trans...

Embodiment 2

[0031] A method for preparing a light-emitting part, which includes a light-leaking optical fiber used to make the light-emitting part, the preparation method being:

[0032] 1) Engraving the light-leakage fiber, so that the laser transmitted in the light-leakage fiber can leak out from the leakage; the part of the fiber that is engraved is defined as the light-leakage fiber, and the part of the fiber that is not engraved is defined as the transmission fiber.

[0033] 2) Red, green, blue, and yellow four-color phosphors are mixed according to the mass percentage of red: 35.1%, green: 38.9%, blue: 18%, yellow: 8%, and then cured on the surface of the light-leaking optical fiber by epoxy resin. The curing process is: add the calculated ratio of fluorescent powder to the calculated ratio of epoxy resin, 1 gram of four-color fluorescent powder mixture: 3 to 6 grams of silica gel or epoxy resin, stir evenly, and use ultrasonic waves for further homogenization treatment , using the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com