Method for applying formulations which contain bacteriorhodopsin onto substrates, and products produced by this method

一种细菌视紫红质、基质的技术,应用在印刷品、运输和包装、印刷的后处理等方向,能够解决图案可见性或可识别性不可能、表面光泽损害图案可见性或可识别性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0128] Example 1: Application by screen printing

[0129] Here, examples are given of free-radical UV-curable PM formulations (GWT: weight percent) with the exclusion of oxygen:

[0130] Film former: HEMA-TMDI 77.20GWT

[0131] Reactive diluent: TPGDA 8.90GWT

[0132] Free radical starter: 2-Hydroxy-2-methyl-1-phenylpropan-1-one 1.75GWT

[0133] Benzophenone 0.45GWT

[0134] Acylphosphine oxide photoinitiator 0.10GWT

[0135] Surfactant: Ethoxylated nonionic fluorosurfactant 0.05GWT

[0136] Rheological additive: pyrogenic silicic acid 0.10GWT

[0137] Pigment: Solvent Red 118 0.05GWT

[0138] μ-powder: according to CH 00684 / 09 and 11.40GWT

[0139] PCT / EP2010 / 053673

[0140] In the case of using said formulations, the pattern is applied by screen printing onto a paper substrate having a thickness of 6 microns to 12 microns.

[0141] Next, the coating is exposed to UV radiation for a period of a few tenths of a second, and the substrate is then calendere...

example 2

[0145] Example 2: Application by flexographic printing

[0146] For flexographic printing use the following PM formulations:

[0147] Film former: HEMA-TMDI 77.20GWT

[0148] Reactive diluent: TPGDA 8.90GWT

[0149] Free radical starter: 2-Hydroxy-2-methyl-1-phenylpropan-1-one 1.75GWT

[0150] Benzophenone 0.45GWT

[0151]Acylphosphine oxide photoinitiator 0.10GWT

[0152] Surfactant: Ethoxylated nonionic fluorosurfactant 0.10GWT

[0153] Rheological additive: pyrogenic silicic acid 0.05GWT

[0154] Pigment: Solvent Red 118 0.05GWT

[0155] μ-powder: According to CH 00684 / 09 and 11.40GWT

[0156] PCT / EP2010 / 053673

[0157] This results in lower viscous colors than for screen printing according to Example 1.

[0158] In the case of using the formulation, the pattern is applied flexographically to a 2 The surface coating weight is on a paper substrate.

[0159] Next, the coating was exposed to UV radiation for a period of a few tenths of a second, and th...

example 3

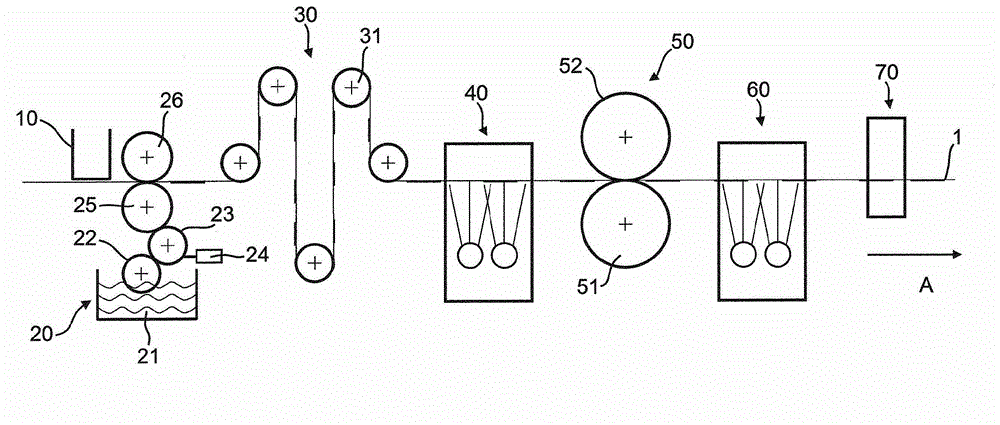

[0163] Example 3: Apparatus for implementing the method

[0164] exist figure 1 A device for carrying out the method according to the invention is shown diagrammatically in very schematic form. A substrate web 1 made of paper passes through the device in direction A. In this case, the substrate web first passes through an antistatic unit 10 for reducing electrostatic charges. In a coating unit 20 for flexographic printing (here by way of example with dyebath 21 , dip roll 22 , anilox roll 23 , doctor blade 24 , plate cylinder 25 and impression cylinder 26 ), the PM formulation will be formed The pattern of is coated on the substrate web 1. In the orientation tunnel 30 with a plurality of rollers 31 , the substrate web 1 is deflected several times and stretched slightly, whereby the color-changing pigments are aligned in a pattern. The patterned substrate is now partially dried in a UV interdryer 40 so that the substrate is then still tacky. Next, the substrate is calender...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com