Internal combustion engine

A technology of internal combustion engine and crankshaft, applied in mechanical equipment, engine control, machine/engine, etc., can solve the problem that internal combustion engine cannot be used, and achieve the effect of avoiding transmission distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

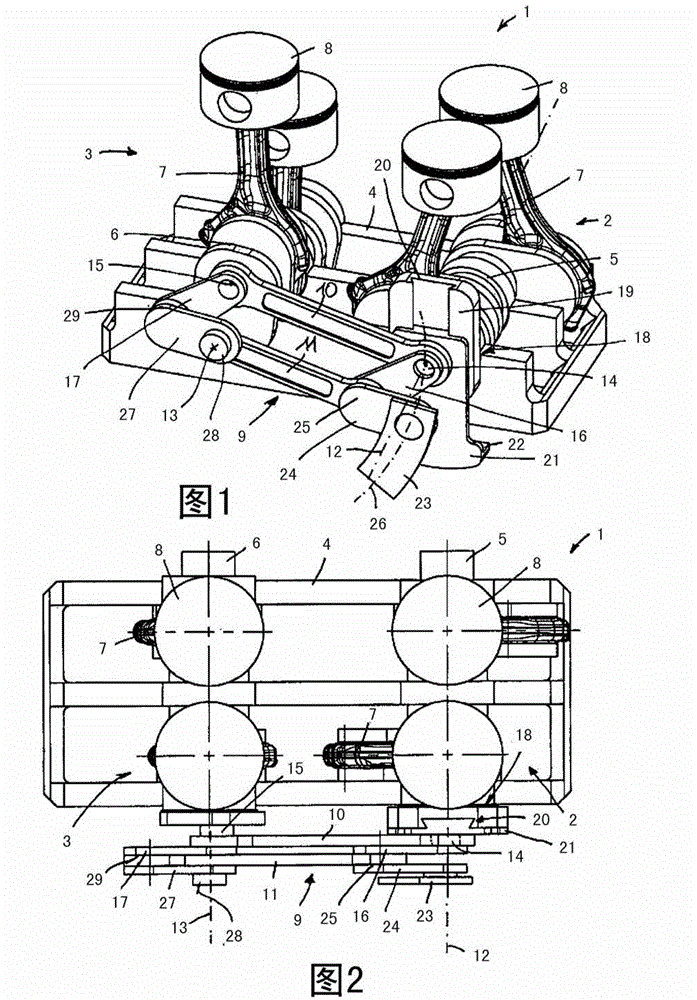

[0020] figure 1 and 2 A schematic illustration of an internal combustion engine 1 with two subunits 2 , 3 is shown from different perspectives. The subunits 2 , 3 are accommodated in a common housing 4 and have cranked crankshaft parts 5 , 6 arranged parallel to one another, on which two pistons 8 are arranged in each case by means of connecting rods 7 to form a four-cylinder piston engine.

[0021] The two crankshaft parts 5 , 6 are positively coupled by means of a coupling device 9 . For this purpose, the coupling device 9 has two connecting rods 10 , 11 , wherein the connecting rod 10 is arranged so as to be rotatable directly on a crank pin 14 , 15 arranged respectively on the crankshaft parts 5 , 6 . The second connecting rod 11 is articulatedly connected to the crank pins 14 , 15 by means of articulated levers 16 , 17 . The length of the articulated levers 16 , 17 displaces the connecting rods 10 , 11 relative to the axes of rotation 12 , 13 of the crankshaft parts 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com