a fire extinguishing composition

A technology for fire-extinguishing composition and fire-extinguishing substance, which is applied to fire-fighting equipment and other directions, can solve the problems that fire-extinguishing agent is not easy to clean, reduce product temperature, and high nozzle temperature, and achieve the effects of shortening effective fire-extinguishing time, enhancing fire-extinguishing performance, and reducing nozzle temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

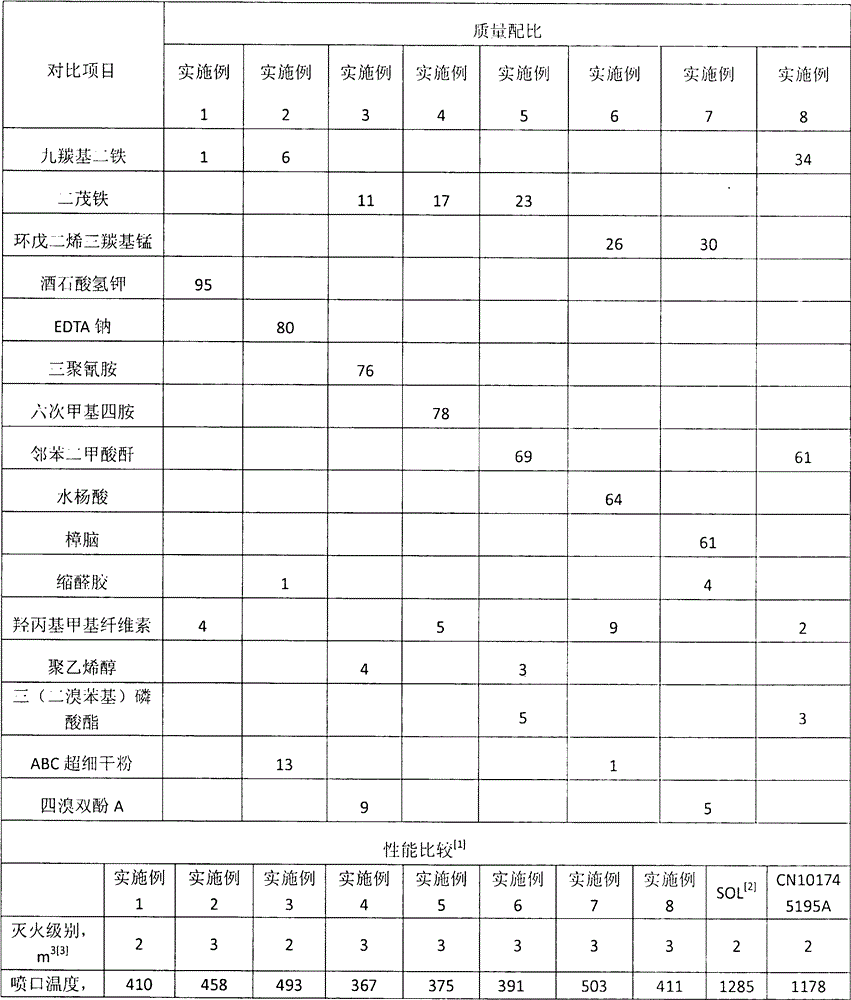

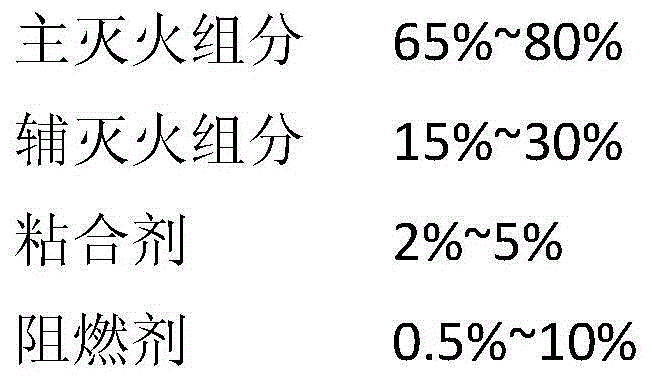

[0017] Take 1 part of nonacarbonyl ferric iron, 95 parts of potassium hydrogen tartrate, and 4 parts of hydroxypropyl methylcellulose, mix the three evenly, add an appropriate amount of water, granulate and dry, and use a rotary tablet machine to make Small pieces of Φ6. When in use, weigh 60 g of the above-mentioned fire extinguishing agent and assemble it with 50 g of aerosol generating agent for use at the same time. The fire extinguishing effect is shown in Table 1.

Embodiment 2

[0019] Take 6 parts of nonacarbonyl ferric iron, 80 parts of sodium EDTA, and 13 parts of ABC superfine dry powder, mix the three evenly, and add 1 part of acetal glue dissolved in an appropriate amount of ethanol, granulate and dry, and extrude with honeycomb ceramics Machine extruded into a Φ25 cylinder with honeycomb voids. When in use, take 3 pieces of the above-mentioned cylinders, about 60g, and assemble them with 50g of aerosol generating agent at the same time. The fire extinguishing effect is shown in Table 1.

Embodiment 3

[0021] Take 11 parts of ferrocene, 76 parts of melamine, and 9 parts of tetrabromobisphenol A, mix the three evenly, and add 4 parts of polyvinyl alcohol dissolved in an appropriate amount of water, granulate and dry it with a rotary tablet machine Make small pieces of Φ6. When in use, weigh 60 g of the above-mentioned fire extinguishing agent and assemble it with 50 g of aerosol generating agent for use at the same time. The fire extinguishing effect is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com