Atomization and evaporation crystallizer

A technology of atomization evaporation and crystallizer, applied in spray evaporation, solution crystallization, etc., can solve the problems of reducing heat exchange efficiency and scaling, and achieve the effects of improving efficiency, less equipment failure, and saving production links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing

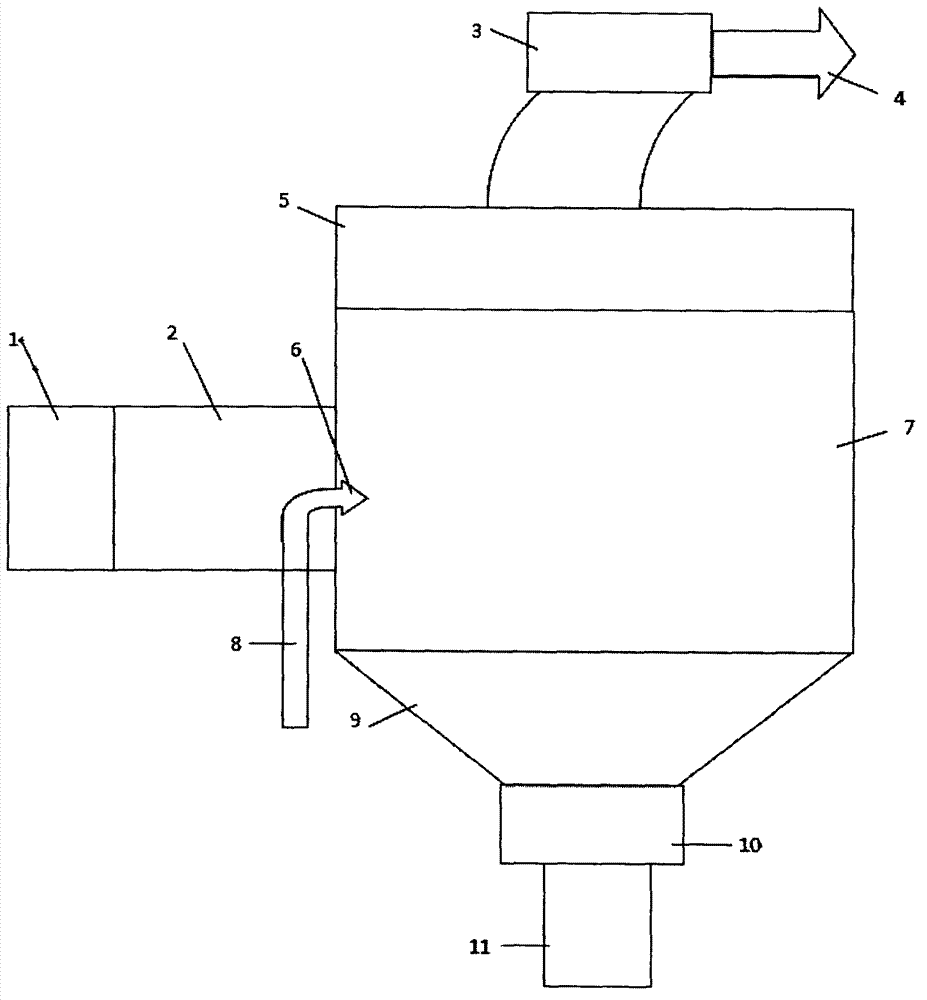

[0012] refer to figure 1 , an atomizing evaporation crystallizer, its structure is mainly composed of fan 1, hot air pipe 2, induced draft fan 3, air outlet 4, bag dust collector 5, atomizing nozzle 6, evaporation chamber 7, material pipe 8, material A warehouse 9, a valve 10, and a discharge port 11 are formed; the fan 1 is connected to the hot air pipe 2, and the top of the material pipe 8 is connected to the atomizing nozzle 6 and communicated with the hot air pipe 2 and the evaporation chamber 7; The upper part of the chamber 7 is connected with the induced draft fan 3 with a bag dust collector 5, the bag dust collector 5 is connected with the induced draft fan 3, and the induced draft fan 3 is provided with an exhaust port 4; the lower part of the evaporation chamber 7 is provided with a material bin 9 , A valve 10 is installed at the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com