Forming method of special-shaped pipe end and special-shaped clamping mold used

A molding method and mold clamping technology, which is applied in the direction of manufacturing tools, feeding devices, positioning devices, etc., can solve problems such as high requirements on the length of straight line sections, failure to meet precision requirements, and damage to pipe ends, so as to improve the processing range and design and manufacture The effect of low cost and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

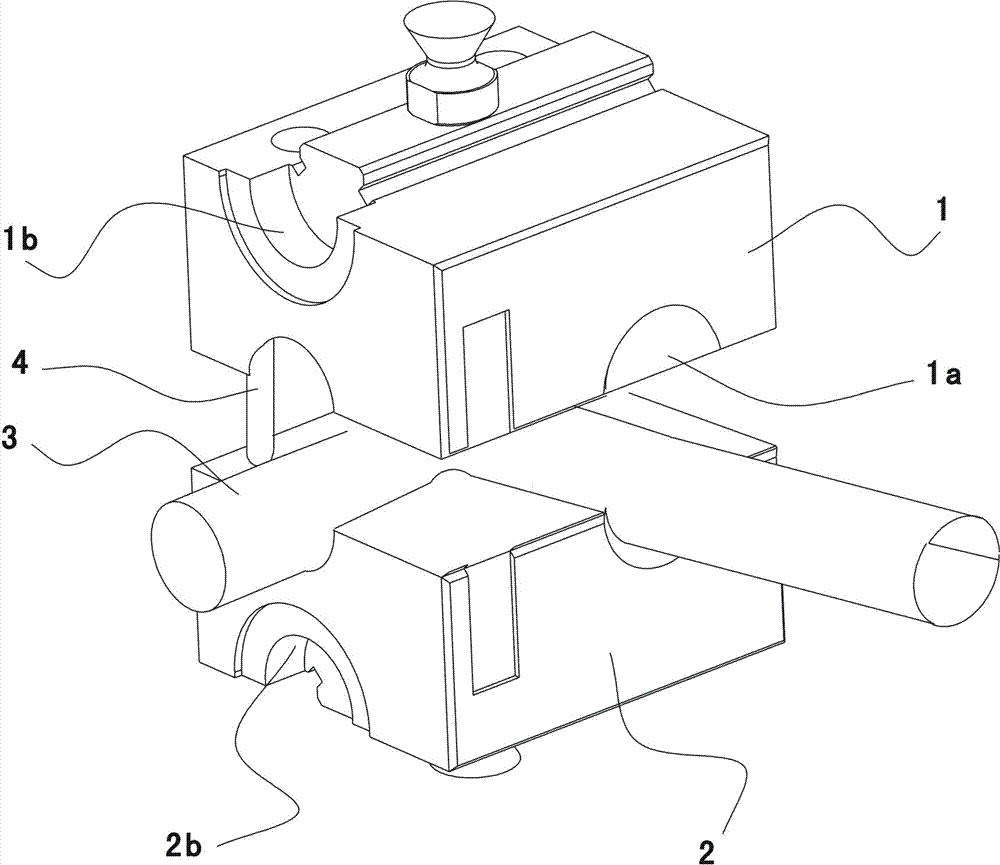

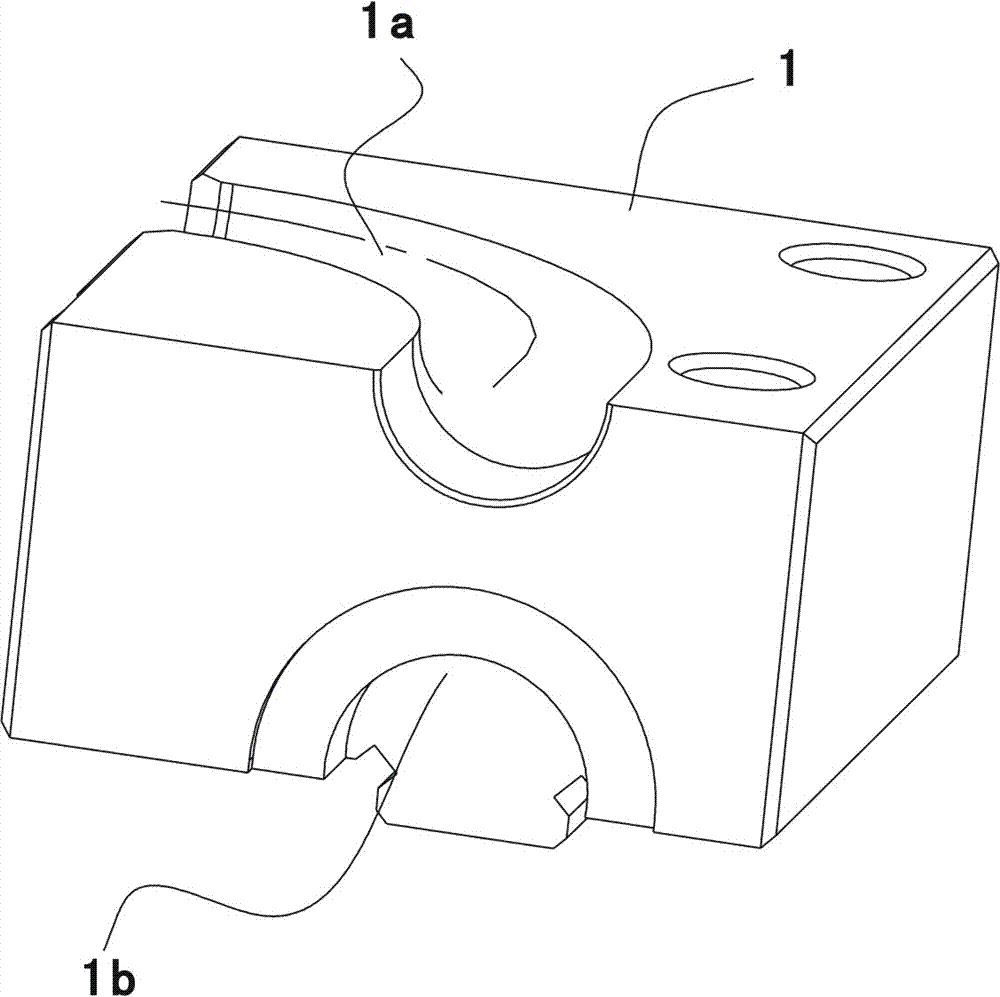

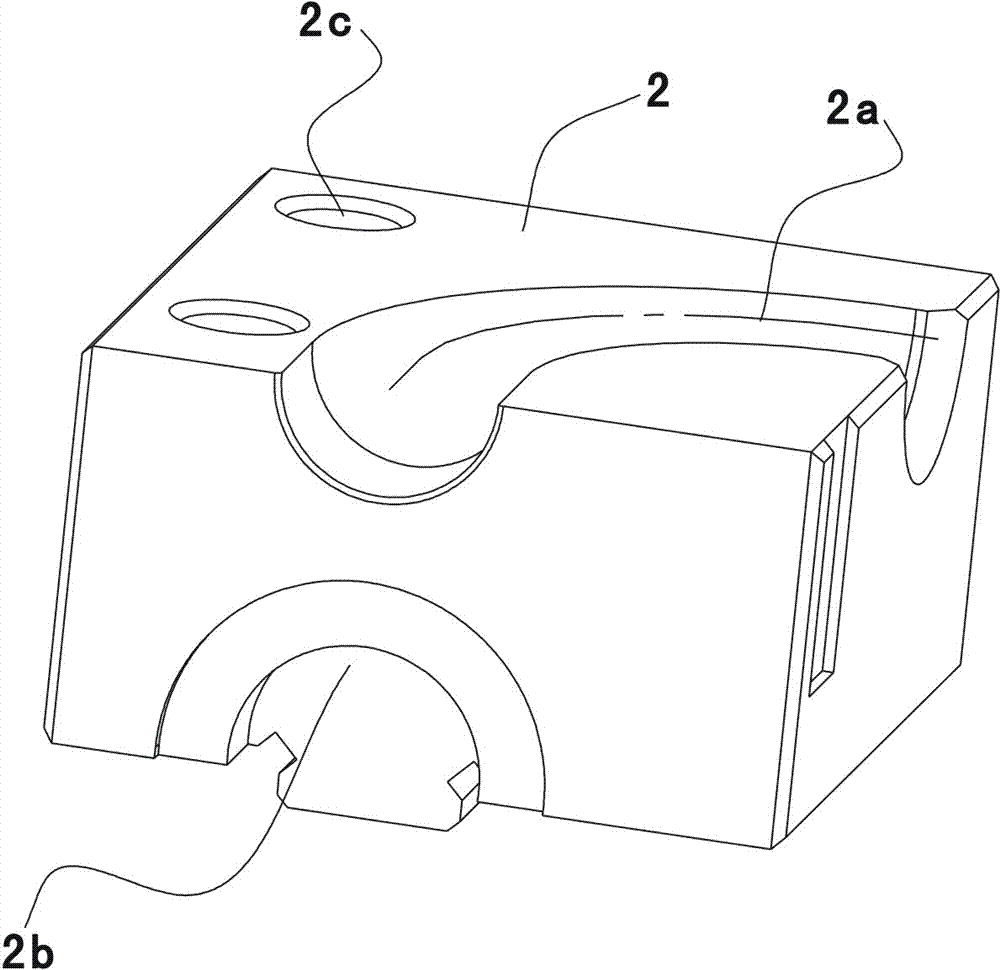

[0030] One of the embodiments of the special-shaped clamping mold of the present invention is as Figures 1 to 3 As shown, the special-shaped clamping mold is mainly composed of an upper clamping mold 1, a lower clamping mold 2 and a positioning device. An upper pipeline cavity 1a is provided on the working surface of the upper clamping mold 1, and an upper pipeline cavity 1a is arranged on the working surface of the lower clamping mold 2. There is a lower pipeline cavity 2a opposite to the upper pipeline cavity 1a. When the lower clamping mold 2 and the lower clamping mold 2 are closed, the upper pipeline cavity 1a and the lower pipeline cavity 2a are docked to form a 90-degree bend The pipeline cavity 6.

[0031] see Figure 4 , the pipeline cavity 6 is composed of a first straight section 61, a second straight section 63 and an arc section 62 with a smoot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com