Welding power supply

A technology of welding power supply and main welding current, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of reducing operation efficiency and arc failure, and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

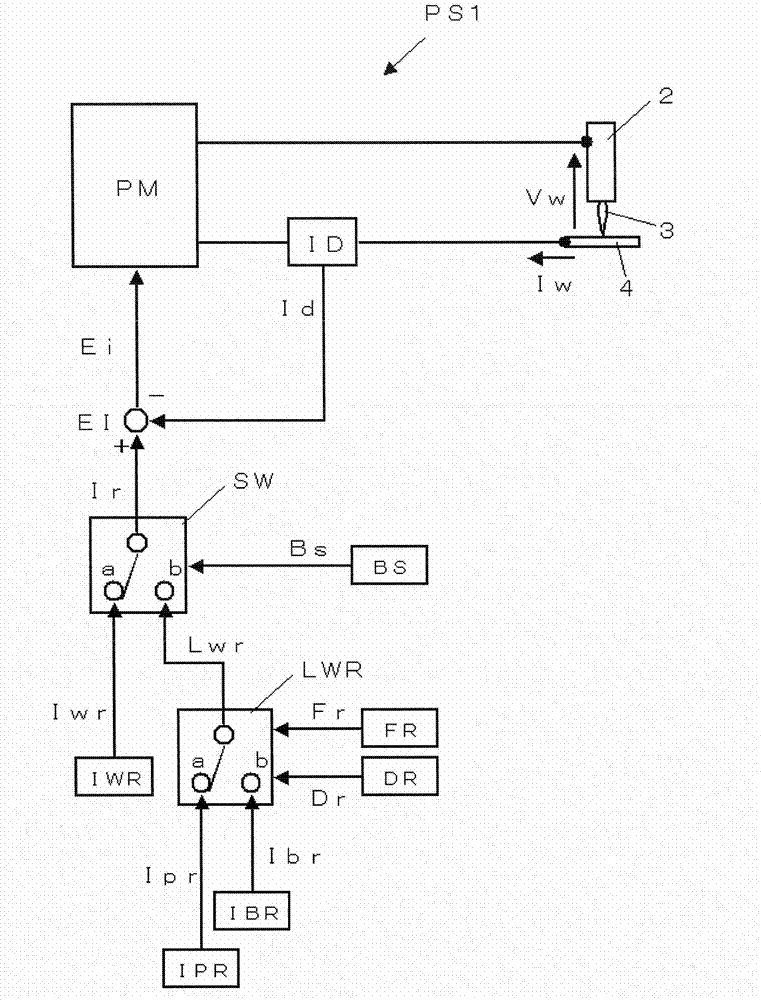

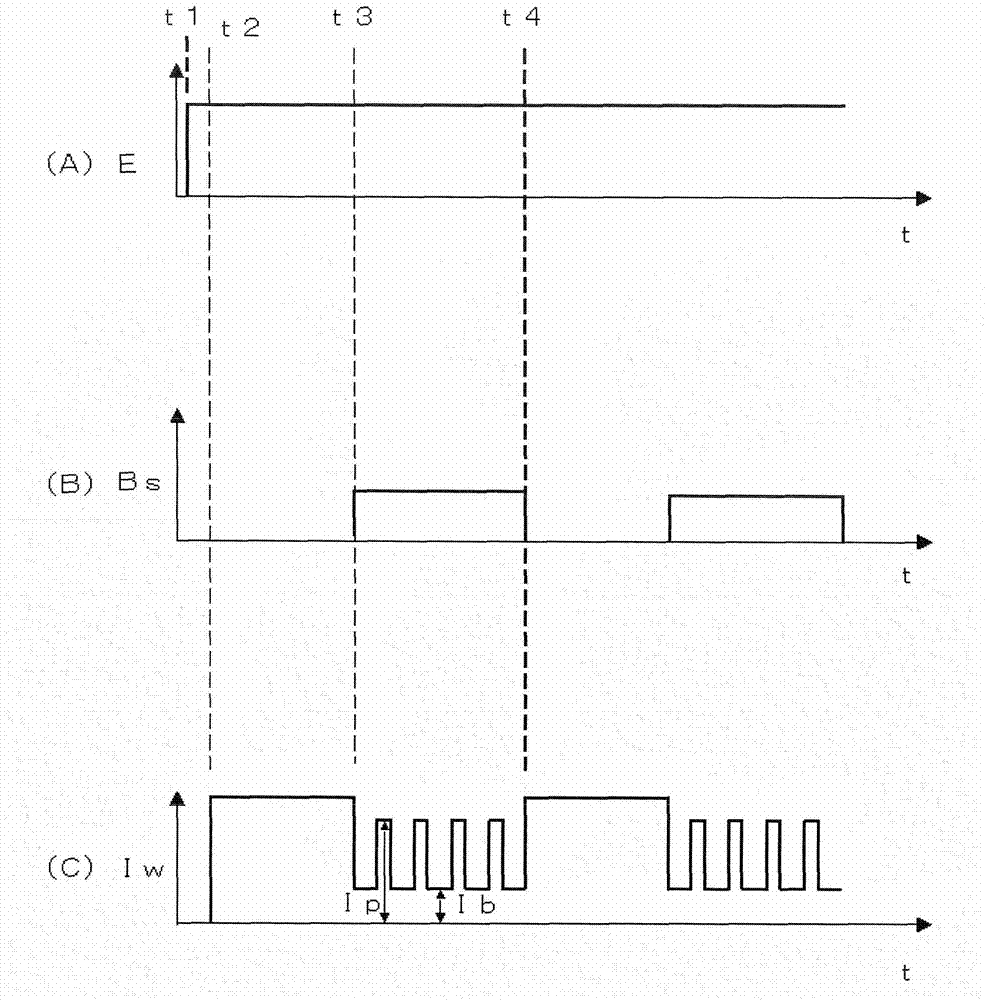

[0070] The embodiments of the invention will be described based on examples and with reference to the drawings. figure 1 It is a block diagram of the welding power source according to Embodiment 1 of the present invention. The welding power source of the first embodiment of the present invention, in order to prevent the burn-through of the penetration weld bead in the prior art, instead of quickly separating the arc welding rod from the base material so as to cut off the arc and cool the base material, Pass low-level current. That is, the main welding current is applied for back cover welding, the low-level current is applied to cool the base material, and the current is applied alternately according to the judgment of the welding operator. When the average current value of the main welding current during the back cover welding is 150A, in order to cool the base material, the low-level current is formed to be a current with an average current value of 30-50A that is smaller tha...

Embodiment approach 2

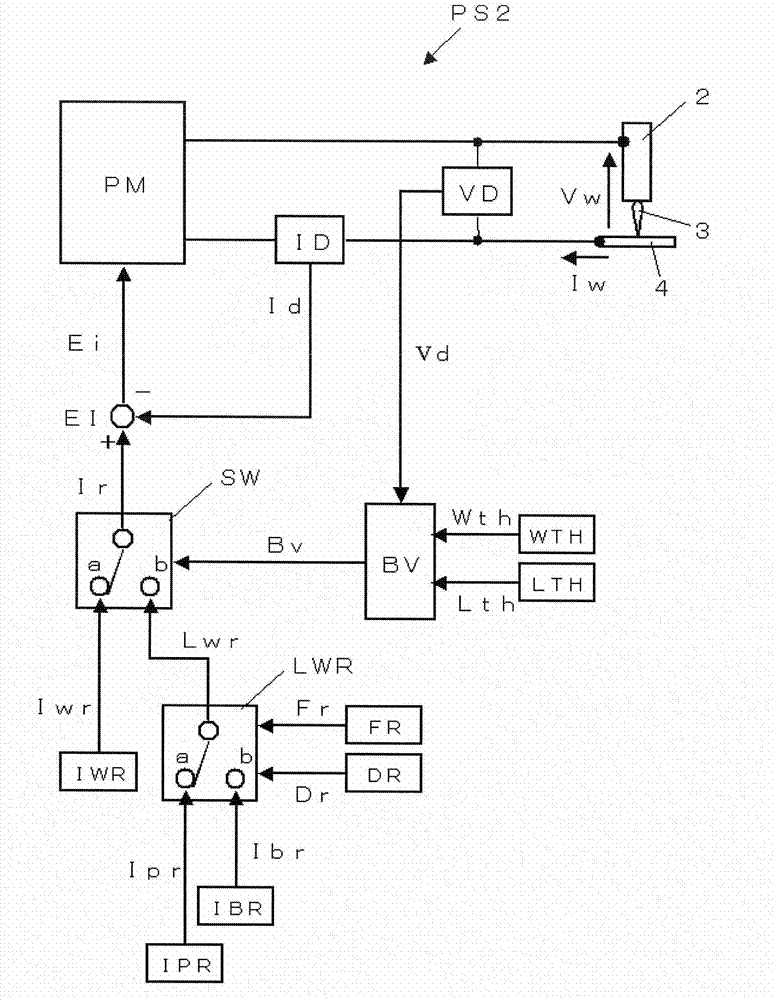

[0082] The welding power source of the second embodiment of the present invention replaces the welding power source of the first embodiment of the present invention by turning on or off the switch start switch BS to pass low-level current, by removing the coated arc electrode 2 from the base material 4 Pull it slightly apart or make it close to pass the low-level current or stop the low-level current. That is, when the arc length when the main welding current is applied is, for example, 5 mm, the arc length for applying the low-level current is formed to be longer than the arc length when the main welding current is applied, and the arc is not cut off. Long, and set to 8-10mm.

[0083] image 3 It is a block diagram of a welding power source according to Embodiment 2 of the present invention. In this figure, the voltage detection circuit VD of the welding power source PS2 detects the welding voltage Vw and outputs a voltage detection signal Vd. The arc length when the welding o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com