Fuel tank and engine

A fuel tank and fuel technology, applied in the direction of engine components, machines/engines, liquid fuel feeders, etc., can solve the problems of unsatisfactory liquid fuel inflow scheme, the configuration of the upper end that cannot be piped, and the vicinity of the center.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

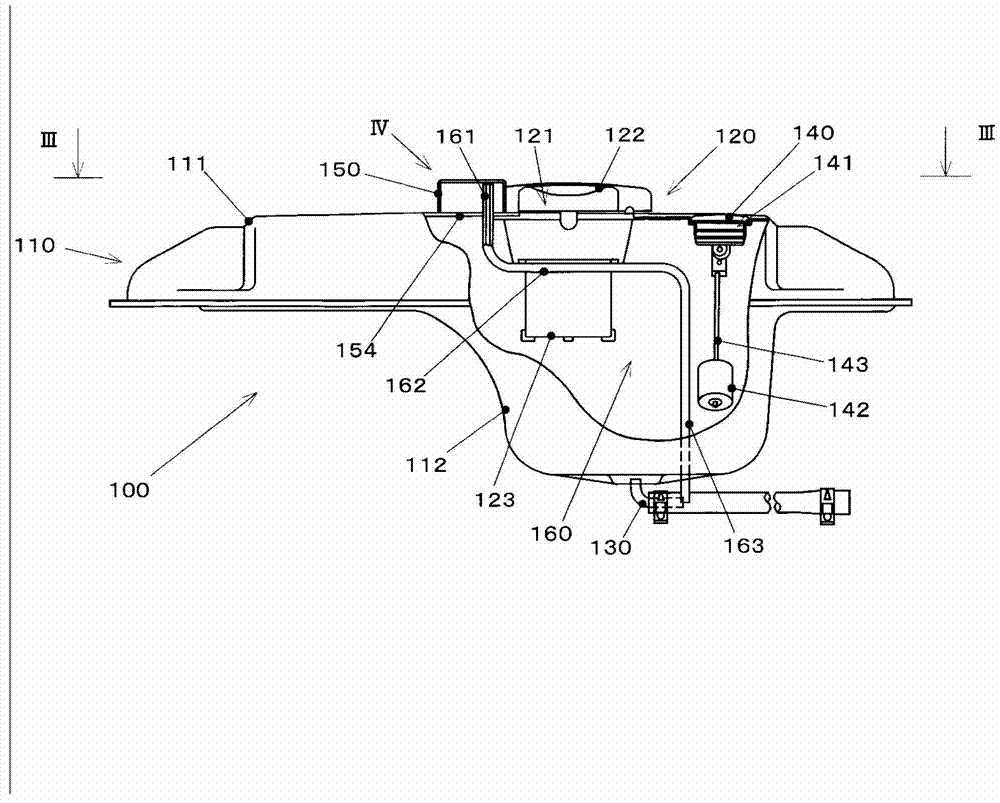

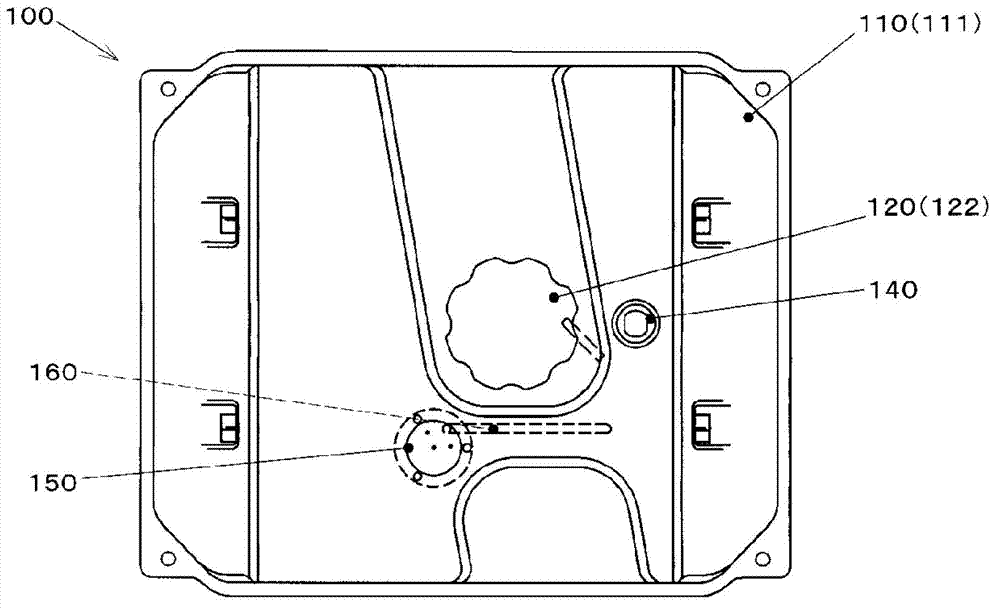

[0089] Next, a first embodiment of a fuel tank and an engine to which the present invention is applied will be described.

[0090] The fuel tank and the engine of the first embodiment can be installed in, for example, a portable small engine-driven generator.

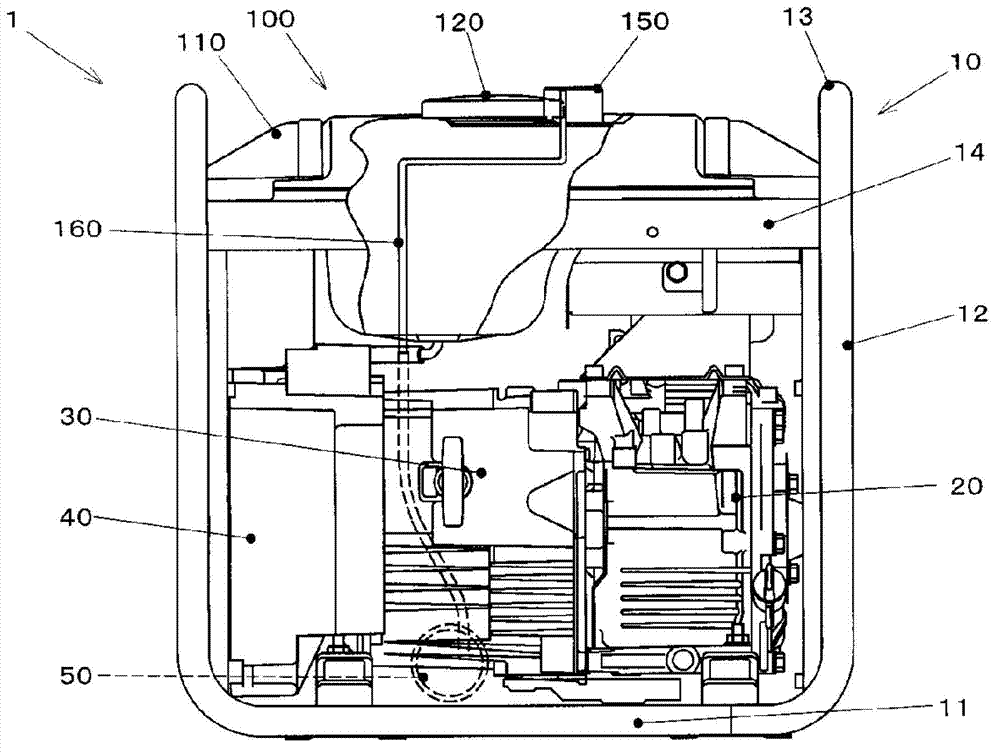

[0091] figure 1 It is a partial cross-sectional side view of an engine-driven generator having the fuel tank and the engine of the first embodiment.

[0092] The engine-driven generator 1 has a frame 10, an engine 20, a recoil starter 30, a blower cover 40, a generator (not shown), a tank 50, a fuel tank 100, and the like.

[0093] The frame 10 is formed, for example, by bending a steel pipe as a base on which the above-mentioned components are mounted.

[0094] From the crankshaft direction (crank axis direction) of the engine 20 ( figure 1 The frame 10 is constituted by both end portions of a pair of lower portions 11 arranged horizontally and parallel in the left-right direction of the paper, and the upper end por...

no. 2 approach

[0149] Next, a second embodiment of the fuel tank using the present invention will be described.

[0150] In addition, the same code|symbol is attached|subjected to the part which is substantially the same as the above-mentioned 1st Embodiment, and description is abbreviate|omitted, and a different point is mainly demonstrated.

[0151] The fuel tank of the second embodiment is provided with a detachable fuel vapor recovery chamber 250 described below instead of the fuel vapor recovery chamber 150 of the first embodiment.

[0152] Image 6 It is an enlarged cross-sectional view of the fuel vapor recovery chamber 250 of the fuel tank of the second embodiment, showing a state in which the fuel vapor recovery chamber is removed.

[0153] Figure 7 It is an enlarged cross-sectional view of the fuel vapor recovery chamber 250 of the fuel tank of the second embodiment, showing a state in which the fuel vapor recovery chamber is installed.

[0154] The fuel vapor recovery chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com