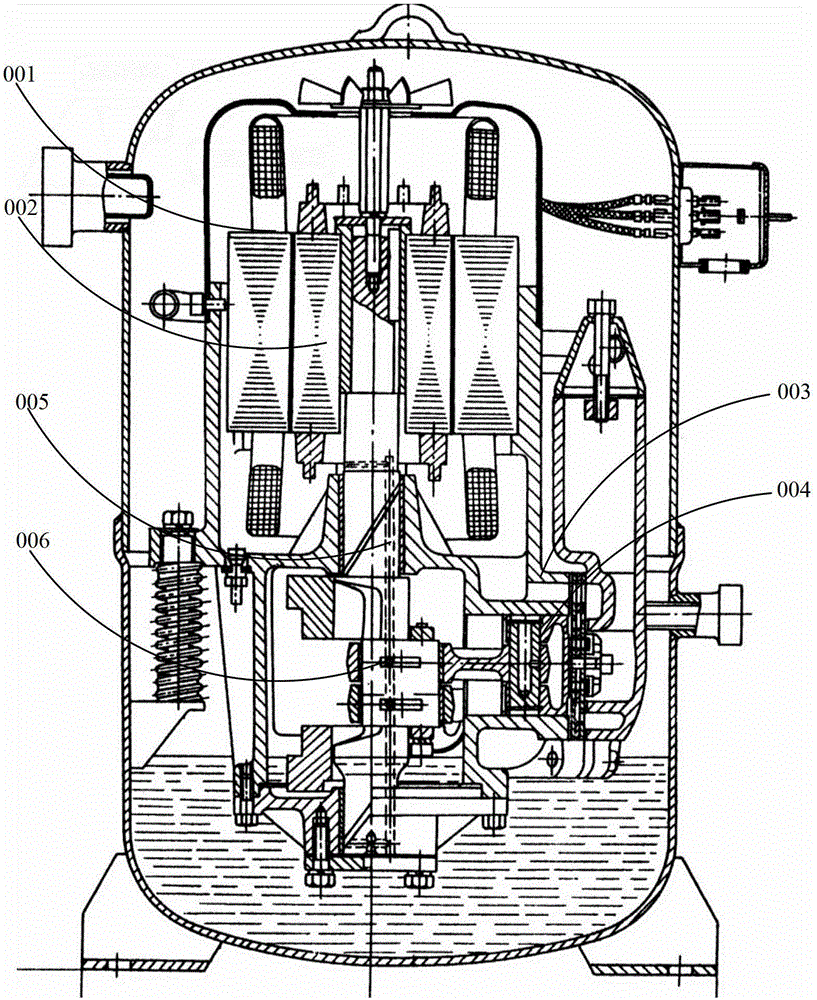

Cross annular compressor

A crossover and compressor technology, applied in the field of compressors, can solve the problems of kinetic energy consumption, difficult to ensure positioning reliability, material fatigue, etc., and achieve the effect of reducing energy transmission loss, improving electromechanical conversion efficiency, and constant electromagnetic driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing and example.

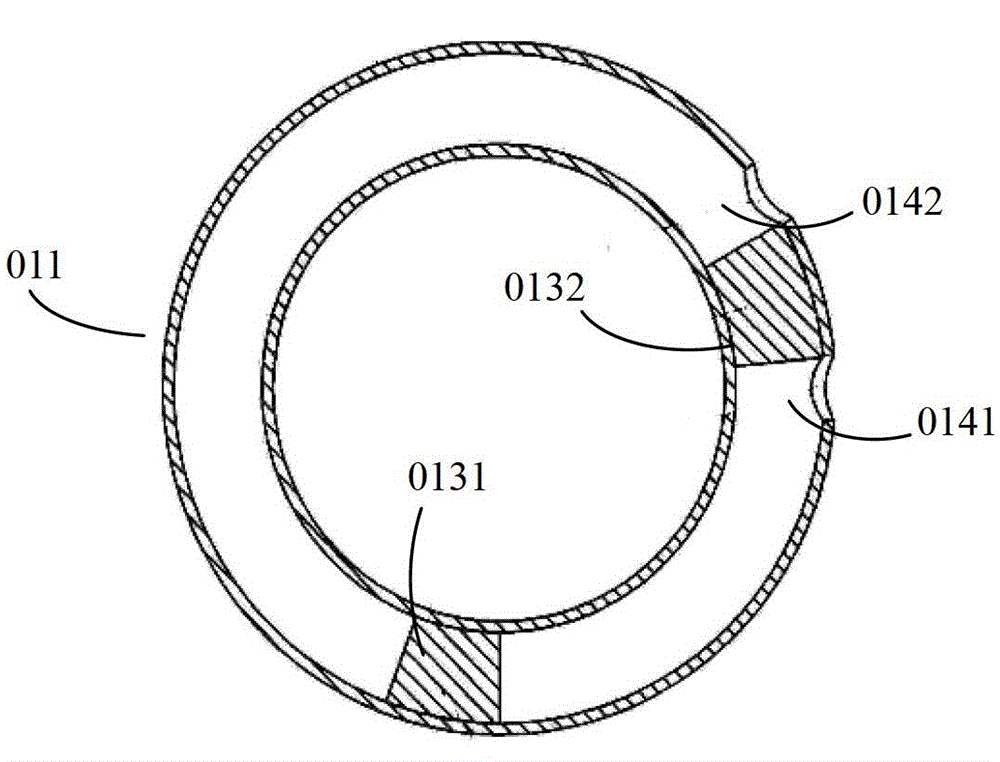

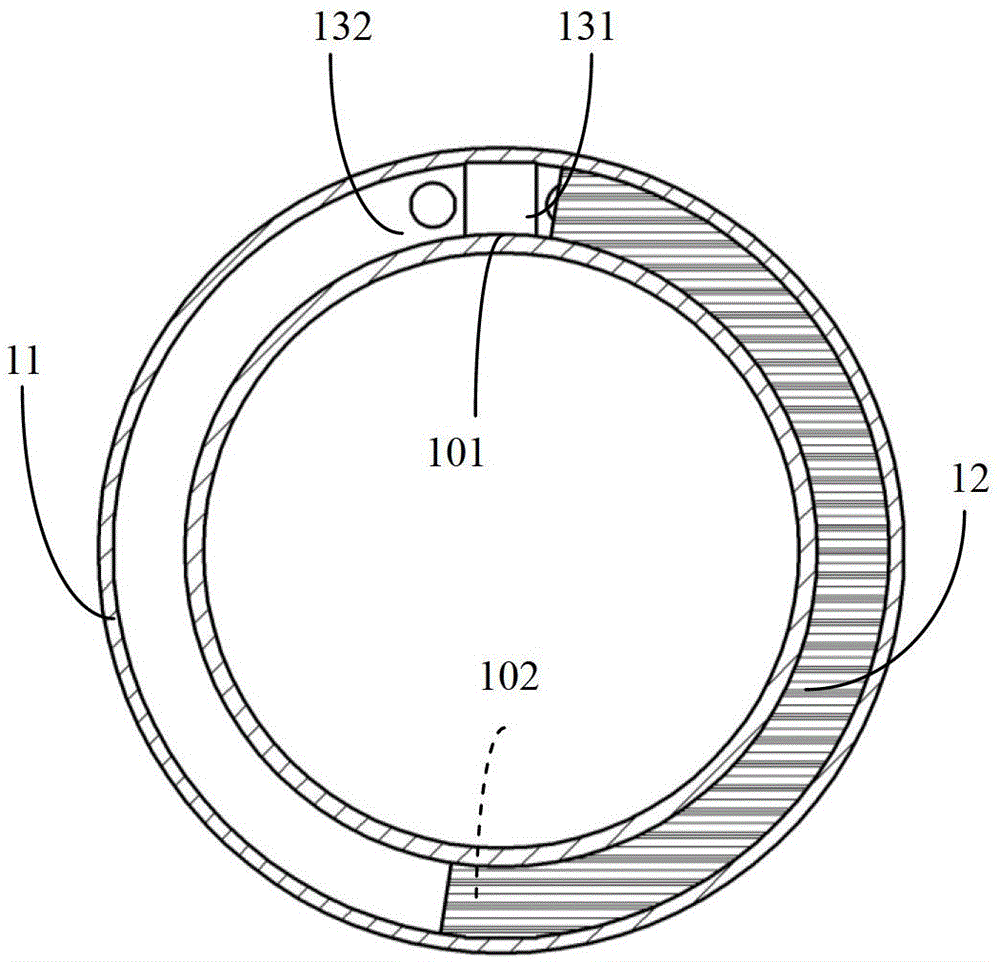

[0022] see image 3 , a ring of a cross-ring compressor, having a cavity 11 . The cavity 11 has a square section. There are openings 101 and 102 on the cavity as the interface between the cavity 11 and the cavity 21 . An exhaust port 131 and an air inlet 132 are arranged on the wall surface of the cavity 11 around the opening 101 . The slider 12 is located in the cavity 11 and can slide along the inner wall of the cavity 11 around.

[0023] Such as Figure 4 As shown, the cross ring compressor consists of two image 3 The annular cavities shown are formed by orthogonal combination.

[0024] The annular cavity 11 needs to have sufficient mechanical strength (such as stainless steel), preferably a non-magnetic and non-conductive material (such as glass fiber reinforced plastics), so that it does not undergo plastic deformation when subjected to a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com