Low-temperature nickel-hydrogen battery and preparation method thereof

A nickel-metal hydride battery, low-temperature technology, applied in the manufacture of nickel batteries, alkaline batteries, battery electrodes, etc., can solve the problems of low charge and discharge efficiency, nickel-metal hydride batteries cannot be charged and discharged normally and effectively, and improve low-temperature performance and increase Effect of Low Temperature Charge and Discharge Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

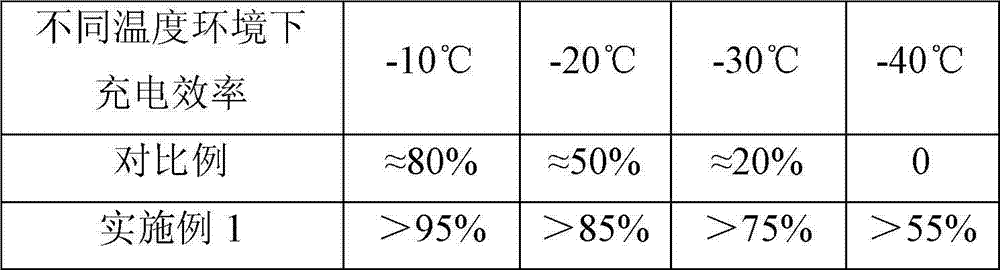

Examples

Embodiment 1

[0055] Positive electrode production:

[0056] (1) Compact the area of the positive electrode substrate foamed nickel from the edge 3mm to form a tight foamed nickel edge;

[0057](2) Mix nickel hydroxide, cobalt-coated spherical nickel hydroxide, cobaltous oxide, and yttrium oxide uniformly in a weight ratio of 82:10:7:1, and then fill it up to step (1) using the nickel-hydrogen battery dry positive electrode process The prepared nickel foam is rolled and cut to make a positive electrode of a nickel-metal hydride battery.

[0058] Negative production:

[0059] (1) The hydrogen storage alloy powder is rolled onto the copper grid of the negative electrode substrate using the nickel-metal hydride battery dry method negative electrode process, and then a layer of polytetrafluoroethylene emulsion is soaked on the surface of the negative electrode substrate (using the polytetrafluoroethylene emulsion used in the prior art ), after drying and rolling, the negative electrode shee...

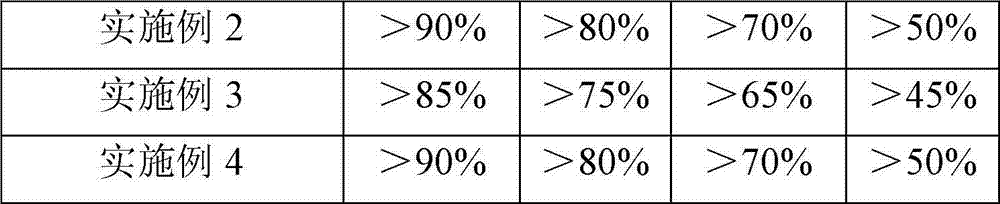

Embodiment 2

[0065] Positive electrode production:

[0066] (1) Compact the area of the positive electrode substrate foamed nickel from the edge 3mm to form a tight foamed nickel edge;

[0067] (2) Mix nickel hydroxide, cobalt-coated spherical nickel hydroxide, cobaltous oxide, and yttrium oxide uniformly in a weight ratio of 82:9:7:2, and then use the nickel-metal hydride battery dry positive electrode process to fill up to step (1) The prepared nickel foam is rolled and cut to make a positive electrode of a nickel-metal hydride battery.

[0068] Negative production:

[0069] (1) The hydrogen storage alloy powder is rolled onto the copper grid of the negative electrode substrate by using the nickel-hydrogen battery dry negative electrode process, and then a layer of polytetrafluoroethylene emulsion is soaked on the surface of the negative electrode substrate, and after drying and rolling, the negative electrode sheet is obtained ;

[0070] (2) Place the negative pole piece in 1.0 g / L...

Embodiment 3

[0075] Positive electrode production:

[0076] (1) Compact the area of the nickel foam of the positive electrode substrate 2 mm from the edge to form a tight foam nickel edge;

[0077] (2) Mix nickel hydroxide, cobalt-coated spherical nickel hydroxide, cobaltous oxide, and yttrium oxide in a weight ratio of 82:8:9:1, and then use the nickel-hydrogen battery dry positive electrode process to fill to step (1) The prepared nickel foam is rolled and cut to make a positive electrode of a nickel-metal hydride battery.

[0078] Negative production:

[0079] (1) The hydrogen storage alloy powder is rolled onto the copper grid of the negative electrode substrate by using the nickel-hydrogen battery dry negative electrode process, and then a layer of polytetrafluoroethylene emulsion is soaked on the surface of the negative electrode substrate, and after drying and rolling, the negative electrode sheet is obtained ;

[0080] (2) Place the negative pole piece in 1.5g / L potassium hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com