A kind of ultra-low temperature battery capacitor and its preparation

A battery capacitance and ultra-low temperature technology, which is applied in the direction of battery electrodes, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problems of increasing the scope of application, and achieve the advantages of diffusion and electron transmission, de-intercalation, and low-temperature charge and discharge efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

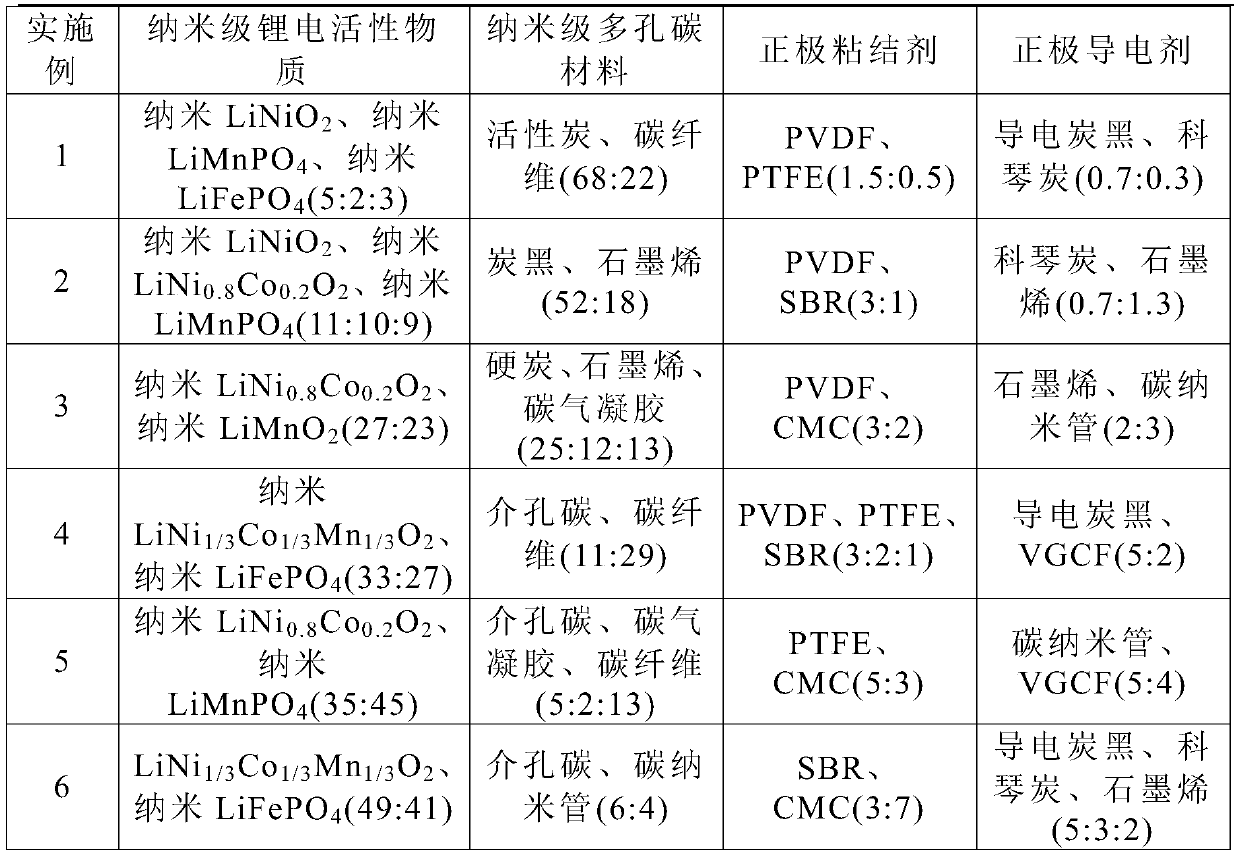

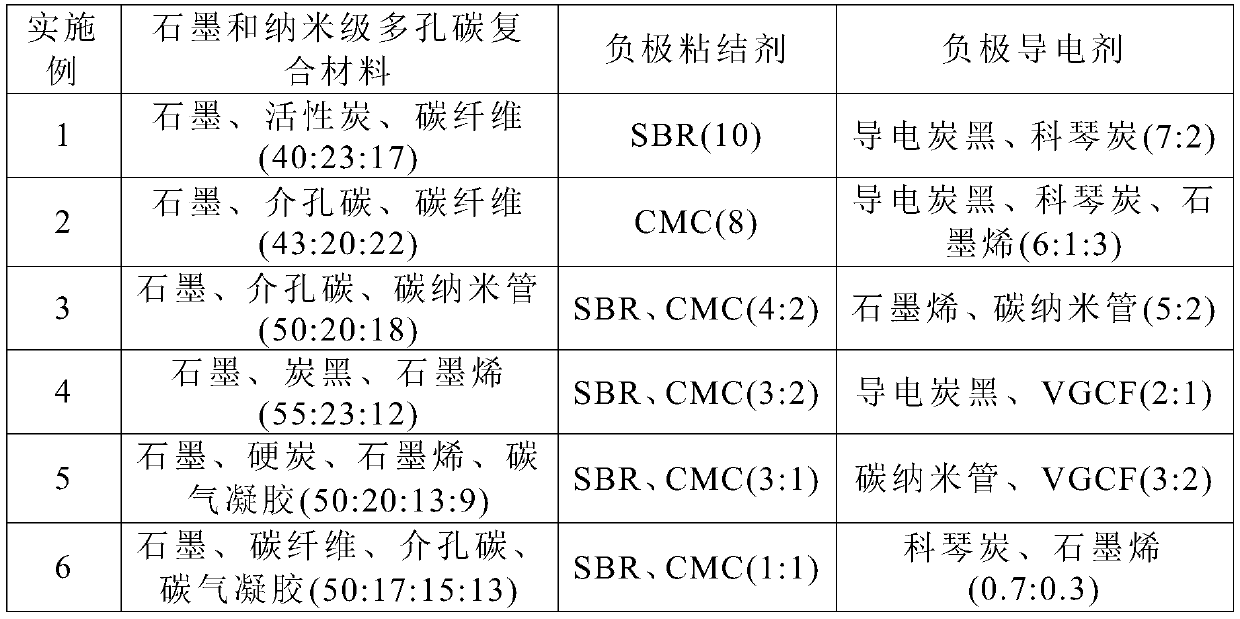

[0041] The ultra-low temperature battery capacitor in the present invention includes a positive electrode sheet, a negative electrode sheet, and a low-temperature electrolyte. The positive electrode sheet includes an aluminum foil coated with a positive electrode material, and the negative electrode sheet includes an aluminum foil sheet coated with a negative electrode material. The positive electrode material is composed of nanoscale lithium electroactive material, nano-scale porous carbon material, positive electrode binder and positive electrode conductive agent, the negative electrode material is compounded from graphite and nano-scale porous carbon composite material, positive electrode binder and positive electrode conductive agent, and the low-temperature electrolyte is composed of multiple solvents , compound electrolyte salt and additives.

[0042] Prepare positive electrode materials, negative electrode materials and low-temperature electrolytes in Examples 1 to 6 acc...

Embodiment 7~12

[0058] The preparation method of ultra-low temperature battery capacitor in the present invention comprises the following steps:

[0059] Prepare the raw materials of the low-temperature electrolyte according to the components in Example 3, add the composite electrolyte salt and additives to the multi-component solvent and mix evenly to make the low-temperature electrolyte;

[0060] Prepare the raw materials of the positive electrode material according to the components in Example 3, dissolve the nanoscale lithium electroactive material, nanoscale porous carbon material, positive electrode binder and positive electrode conductive agent in the nitrogen methyl group after weighing the mass ratio in Table 4 Stir evenly in pyrrolidone to make a positive electrode slurry, and coat it on an aluminum foil to make a positive electrode sheet;

[0061] Prepare the raw material of negative electrode material according to the component in embodiment 3, graphite and nanoscale porous carbon...

Embodiment 13~17

[0069] Prepare the raw materials of the low-temperature electrolyte according to the components in Examples 1, 2, 4-6, respectively, add the composite electrolyte salt and additives to the multi-component solvent and mix well to make the low-temperature electrolyte;

[0070]Prepare the raw materials of the positive electrode material according to the components in Examples 1, 2, 4 to 6 respectively, and the nano-scale lithium electroactive material, the nano-scale porous carbon material, the positive electrode binder and the positive electrode conductive agent according to the mass ratio in Example 10 After weighing, dissolve in nitrogen methyl pyrrolidone and stir evenly to make a positive electrode slurry, which is coated on an aluminum foil to make a positive electrode sheet;

[0071] Prepare the raw material of the negative electrode material according to the components in Examples 1, 2, 4 to 6, dissolve after weighing graphite and nano-scale porous carbon composite materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com