Fabric for airbag, using polyethylene terephthalate fiber with excellent heat resistance

A technology of ethylene glycol phthalate and heat resistance, which is applied in the field of airbag fabrics of ester fibers, can solve problems such as cracking, and achieve the effect of easy storage and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

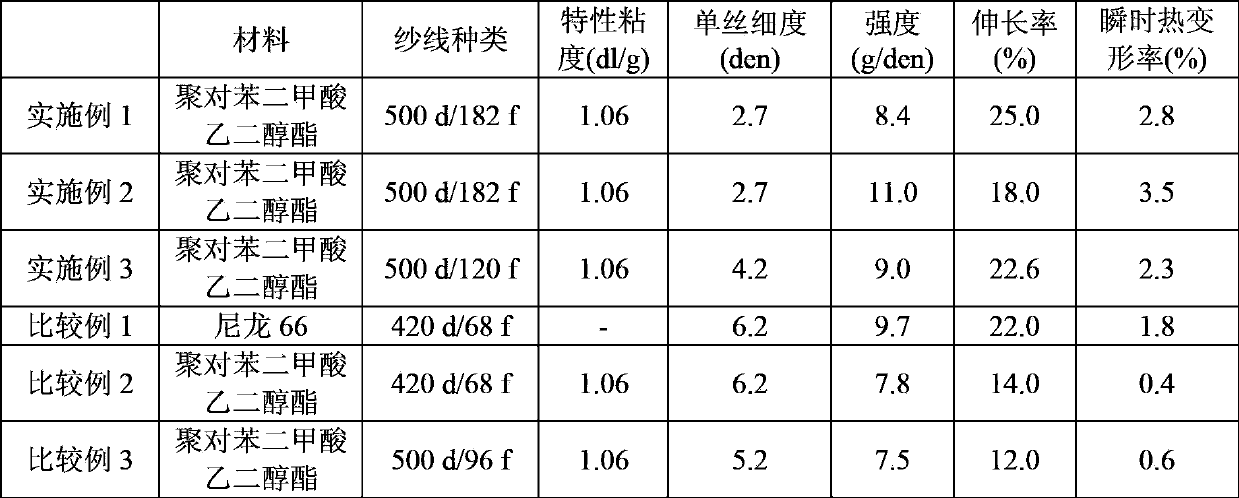

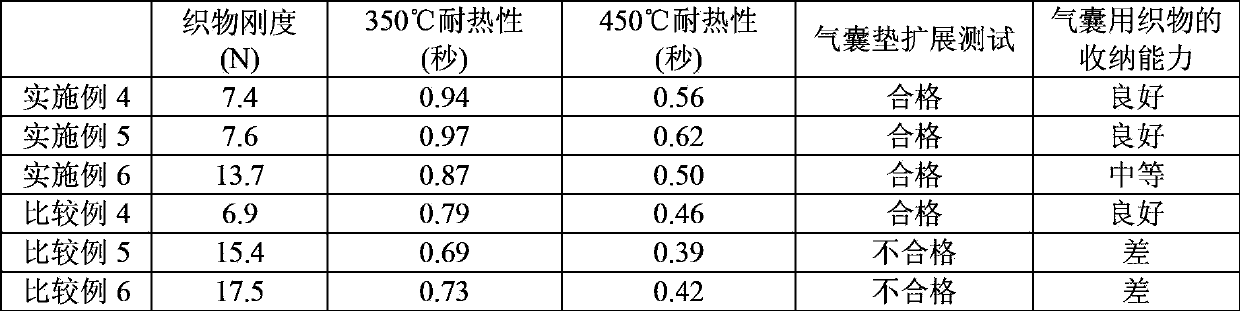

Embodiment 1

[0059] Using a rapier loom, the polyethylene terephthalate yarn having the characteristics listed in Table 1 is used to manufacture gray fabrics for air bags by the plain weave method so that the fabric density thereof is 50 wefts or more in both the weft and warp directions. warp / inch.

Embodiment 2

[0061] Gray fabrics for airbags were manufactured from polyethylene terephthalate yarns having the characteristics listed in Table 1 by the method described in Example 1.

Embodiment 3

[0063] Gray fabrics for airbags were manufactured from polyethylene terephthalate yarns having the characteristics listed in Table 1 by the method described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com