An antimony doped sno 2 Preparation method of @carbon nanotube composite electrothermal film

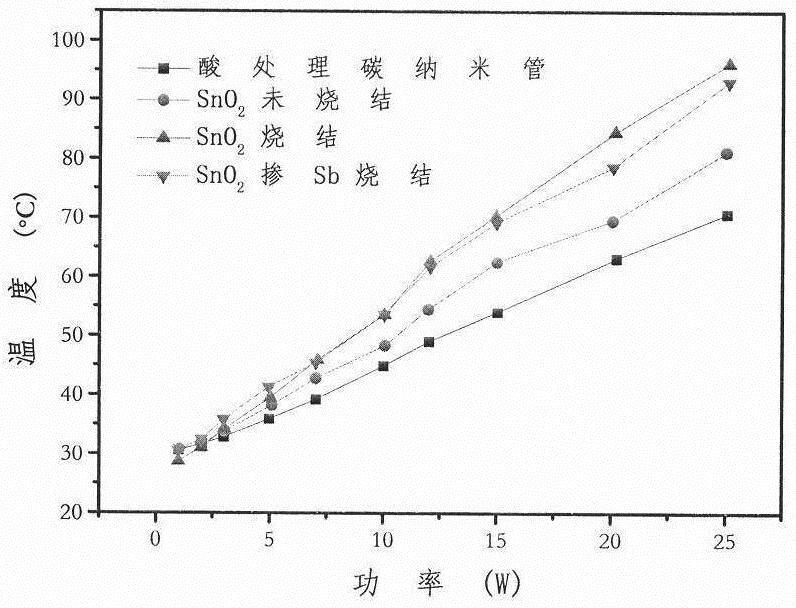

A technology of carbon nanotube composite and carbon nanotube film, which is applied in the field of electric heating film material preparation, can solve the problems of poor long-term stability and low thermal conversion rate of carbon nanotube film, achieve an increase in heating rate and overcome the poor flexibility of oxides , High heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

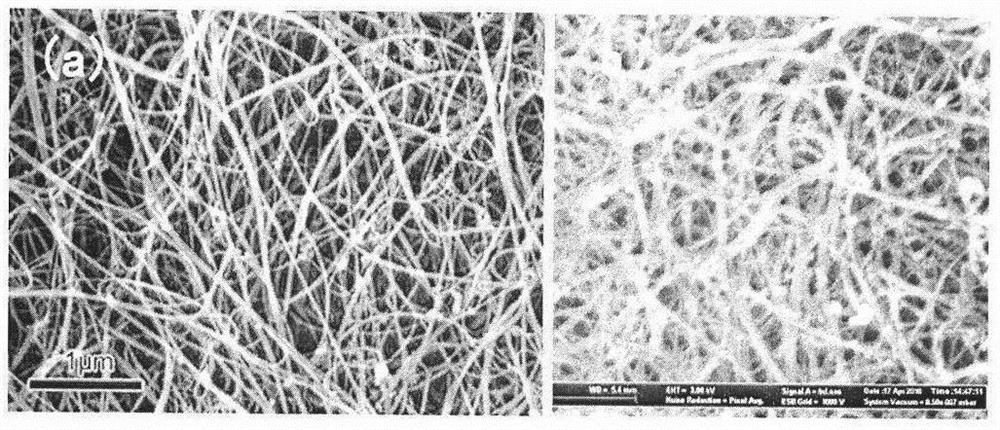

[0022] The area will be 10 × 10cm 2 The carbon nanotube film was soaked in hydrochloric acid for 6 hours, rinsed with deionized water and ethanol respectively, then soaked in concentrated nitric acid for 6 hours, rinsed with deionized water and ethanol again, and placed in an oven at a constant temperature of 60 °C. After drying, a two-step acid-treated carbon nanotube film sample was obtained.

Embodiment 2

[0024] On the basis of Example 1, the two-step acid-treated film was immersed in SnCl 4 , NaOH and SbCl 3 In the mixed reaction solution, the solvent is a mixture of deionized water and ethanol, hydrothermally heated in a 150°C reactor, rinsed and then dried; finally, the dried film is placed in a tube furnace and heated in an inert gas N 2 Under the protection, the temperature was raised to 500°C for 20 minutes at a rate of 5°C / min. After cooling, the film was taken out to obtain the final product, antimony-doped SnO. 2 @Carbon nanotube composite electrothermal film material.

Embodiment 3

[0026] SnCl 4 , NaOH and SbCl 3 The mixed reaction solution of SbCl 3 Removed, other conditions are the same as in Example 2 to obtain SnO 2 @Carbon nanotube composite film material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com