Preparation method for flexible high-molecular PTC material

A flexible polymer and ratio control technology, which is applied in the field of preparation of flexible polymer PTC materials, can solve the problems of lack of flexibility and large amount of carbon black added, and achieve the effect of reduced carbon black amount and low conductive threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

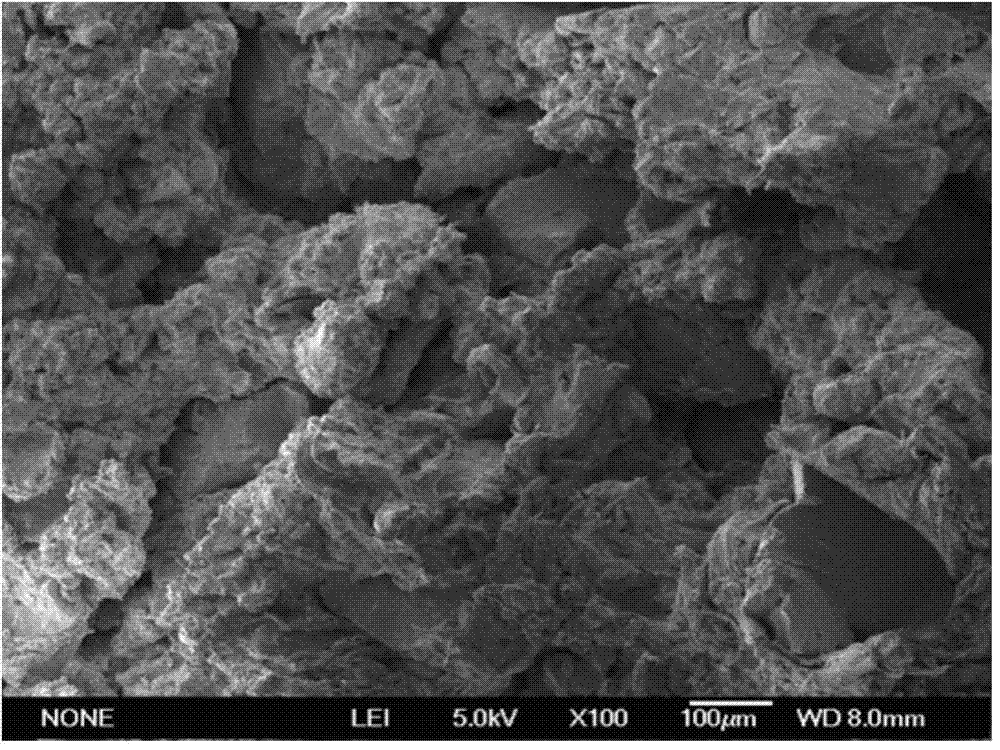

[0025] Example 1: Preparation of PTC materials based on blended HDPE / carbon black / SBS / WGRT

[0026] At room temperature, first add 20.0 grams of HDPE particles into a 160°C open mill with a roller spacing of 1.0 mm for melting and plasticization; after the resin is completely plasticized, add 3.6 grams of N220 carbon black, and the mixing time is 5 minutes ; Then add 5.0 grams of SBS and knead for 3 minutes; then add 80.0 grams of WGRT and continue to melt and blend for 8 minutes; increase the roller distance and lower the sheet;

[0027] Mold the obtained melt-blended sample with a hydraulic hot plate vulcanizer to obtain a sample of about 1mm. Molding conditions: the stainless steel mold is lined with a polytetrafluoroethylene isolation film, the sample is preheated at 165°C for 5 minutes, and the air is exhausted 3 times , and then hold the pressure at 10MPa for 8min, take out the cold press for 8min and then release the sheet; 60 ) for irradiation cross-linking at a dose ...

Embodiment 2

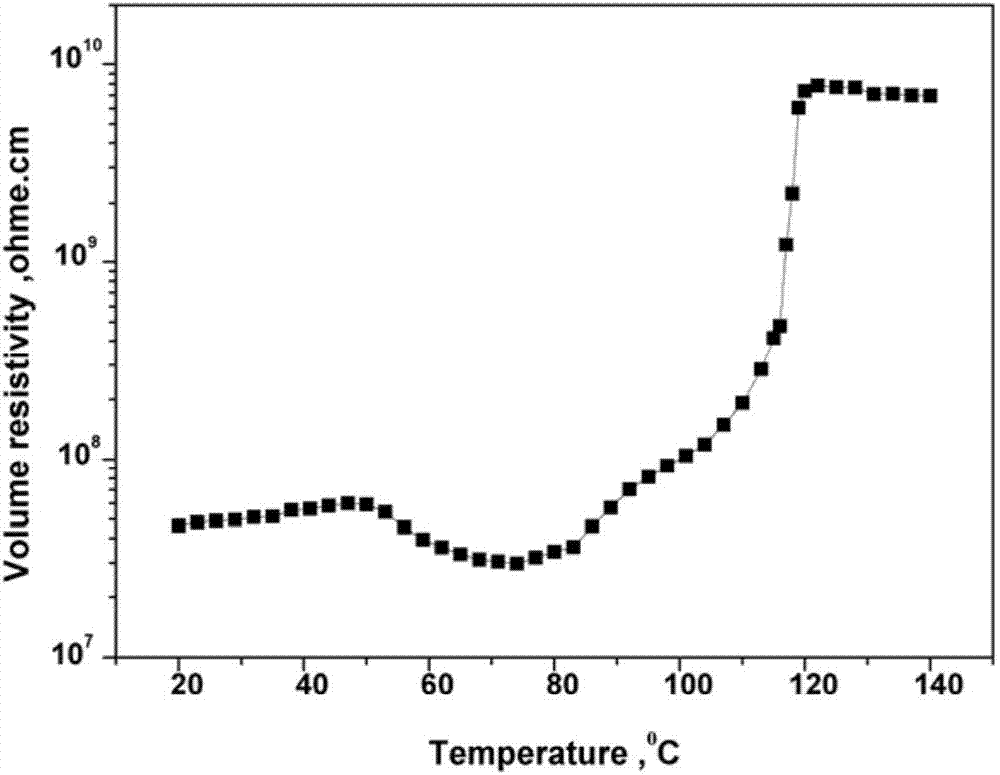

[0029] Example 2: Preparation of PTC materials based on blended HDPE / carbon black / SBS / WGRT

[0030] At room temperature, first add 40.0 grams of HDPE particles into an open mill at 165°C with a roller spacing of 1.0 mm for melting and plasticization; after the resin is completely plasticized, add 8.0 grams of N220 carbon black, and the mixing time is 8 minutes ; Then add 4.0 grams of SBS and knead for 3 minutes; then add 60.0 grams of WGRT and continue to melt and blend for 6 minutes; increase the roller distance and lower the sheet;

[0031] Mold the obtained melt-blended sample with a hydraulic hot plate vulcanizer to obtain a sample of about 1mm. Molding conditions: the stainless steel mold is lined with a polytetrafluoroethylene isolation film, the sample is preheated at 165°C for 5 minutes, and the air is exhausted 3 times , and then hold the pressure for 8min under the pressure of 12MPa, take out the cold press for 8min and then release the sheet; 60 ) for irradiation cro...

Embodiment 3

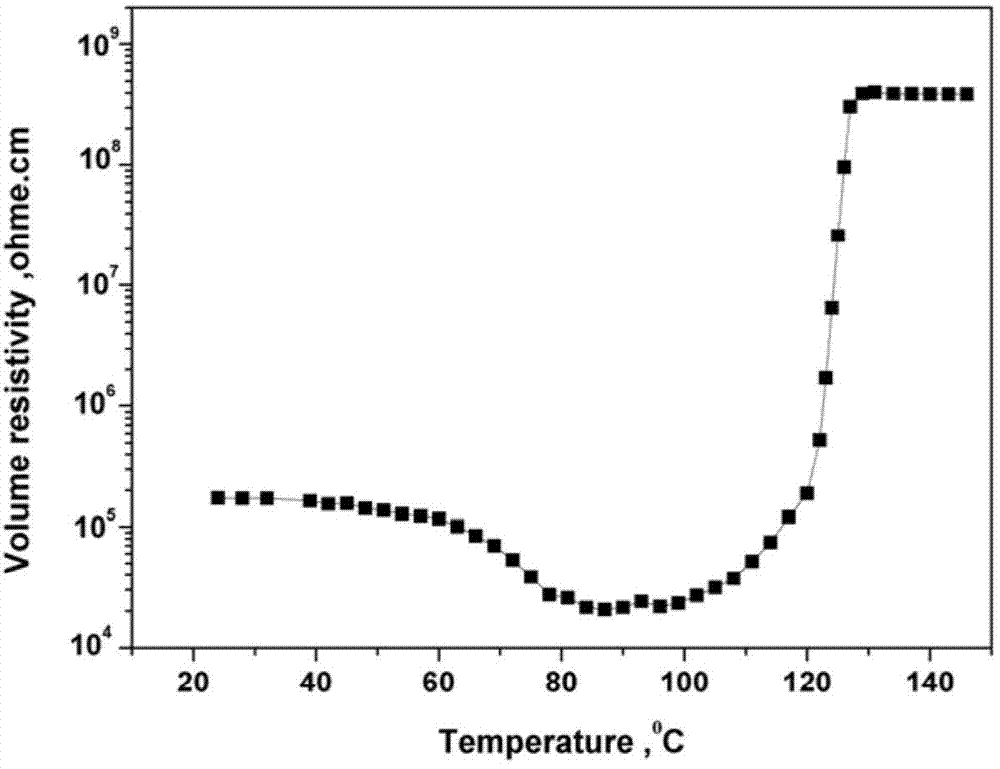

[0033] Example 3: Preparation of PTC materials based on blended HDPE / carbon black / SBS / WGRT

[0034] At room temperature, first add 50.0 grams of HDPE particles into a 170°C open mill with a roller spacing of 1.0mm for melting and plasticization; after the resin is completely plasticized, add 11.0 grams of N220 carbon black and mix for 10 minutes ; Then add 3.0 grams of SBS and knead for 3 minutes; then add 50.0 grams of WGRT and continue to melt and blend for 5 minutes; increase the roller distance and lower the sheet;

[0035] Mold the obtained melt blended sample with a hydraulic hot plate vulcanizer to obtain a sample of about 1mm. Molding conditions: the stainless steel mold is lined with a polytetrafluoroethylene isolation film, the sample is preheated at 165°C for 5 minutes, and the air is exhausted 3 times , and then hold the pressure for 8min under the pressure of 15MPa, take out the cold press for 8min and then release the sheet; 60 ) for irradiation cross-linking at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com