Dump truck

A dump truck and cooling oil technology, which is applied to vehicle parts, brakes, gear lubrication/cooling, etc., can solve problems such as increased horsepower consumption, and achieve the effects of preventing leakage and suppressing internal pressure rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, one embodiment of the present invention will be described based on the drawings.

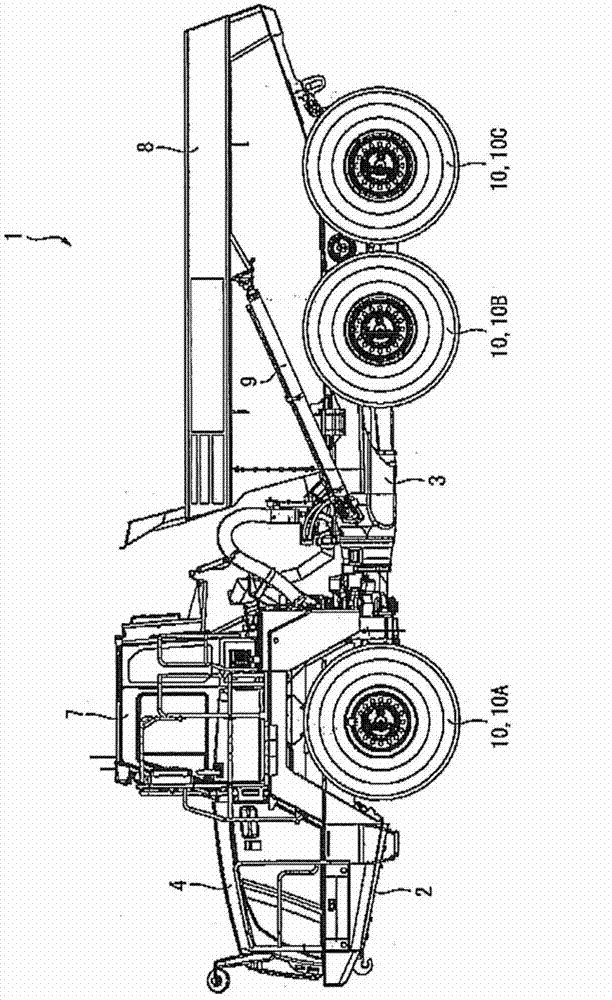

[0026] figure 1 , figure 2 Among them, the dump truck 1 is configured as an articulated dump truck in which a front frame 2 and a rear frame 3 are flexibly connected.

[0027] An engine 5 ( figure 2 ). The rear part of the front frame 2 is equipped with a transmission 6 ( figure 2 ), above which a cab 7 is arranged.

[0028] A vehicle body 8 is mounted on the rear frame 3 , and the vehicle body 8 heaves relative to the rear frame 3 by a pair of left and right hydraulic actuators 9 .

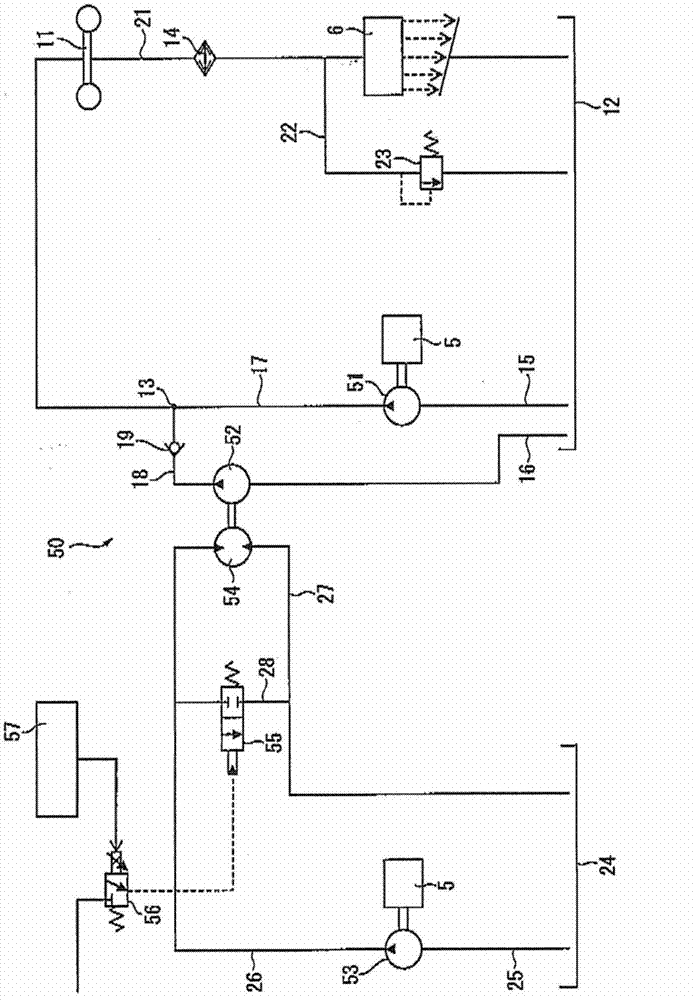

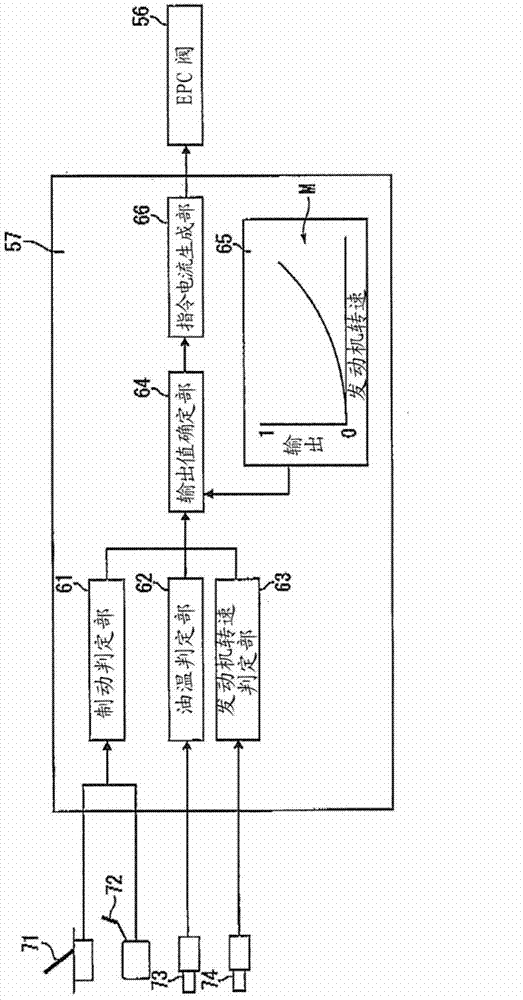

[0029] In addition, a pair of left and right front wheels 10 (10A) are provided on the front frame 2, and a pair of left and right rear front wheels 10 (10B) and rear rear wheels 10 (10C) are provided on the rear frame 3, and the entirety of the six wheels is driven. . The cooling system 50 of the present embodiment is applied to the center brake 11 as a brake device for the rear front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com