Pressure and program control combined electric heating cooking utensil

A technology for cooking utensils and electric heaters, which is applied to cooking utensil lids, cooking utensils, household utensils, etc. It can solve the problems of different regulation of boiling and tumbling intensity, and achieve the effects of cleaning, improving control accuracy, and reducing thermal inertia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

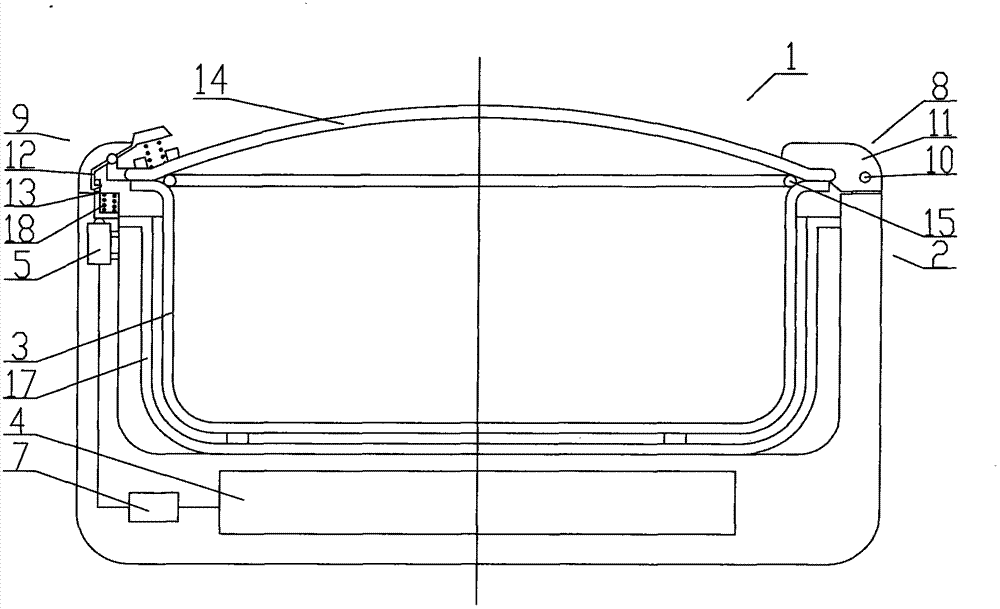

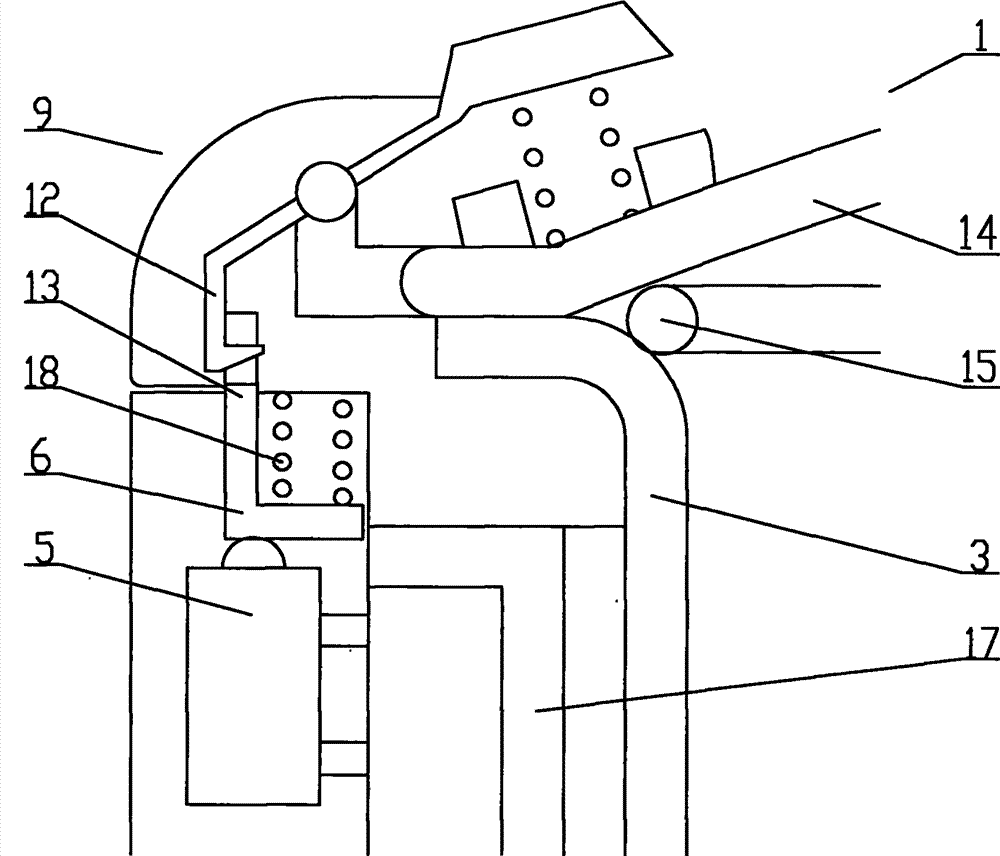

[0021] Example 1: Reference figure 1 , figure 2 , The pot cover component 1 of this embodiment includes a pot cover 14 . Pot cover 14 adopts glass or transparent plastic to make. Through the see-through cover, the user can directly observe the cooking status of the food in the pot. Sealing ring 15 is made of silicon rubber. When the pot cover 14 was displaced upwards under the pressure in the pot, the sealing ring 15 arranged between the pot cover 14 and the inner pot 3 should ensure the sealing of the pot cover 14 and the inner pot 3 during dynamic displacement. The pressure control mechanism and the locking mechanism 9 are arranged on the same side. The setting position of the pressure control mechanism and the connection relationship with other parts should meet: when the pot cover part 1 is fastened in place, the gravity of the pot cover part 1 can touch the pressure switch 5 to make it in the open state. And when the pressure in the pot drives the pot cover part 1 t...

Embodiment 2

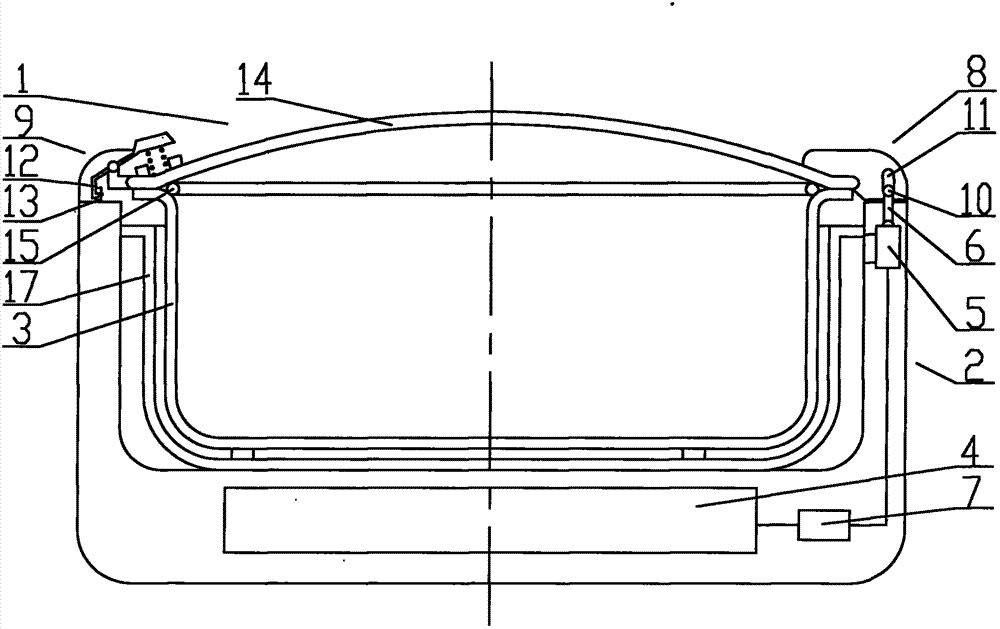

[0026] Example 2: see image 3 , Figure 4 , the manufacturing and setting of the pot lid component 1 in this embodiment, and the setting and connection relationship of the program control mechanism 7 refer to the first embodiment. Inner pot 3 adopts ceramic material to make, and electric heater 4 adopts infrared heater (as quartz glass tube infrared heater). The support and fixation of the electric heater 4 need to adopt a lightweight structure in order to effectively reduce thermal inertia. Outer pot 17 can adopt steel plate to make. At the bottom of the outer pot 17, a heat-resistant glass plate can be arranged to facilitate radiation heat transfer and isolation. The buckle 12 in the buckle lock mechanism 9 is fixedly arranged on the pot cover part 1 , and the lock hook 13 is fixedly arranged on the pot body part 2 . After the clasp 12 and the lock hook 13 are locked, the lock hook 13 cannot move up and down following the pot cover part 1 . The setting positions of cla...

Embodiment 3

[0029] Embodiment 3: as Figure 5 As shown, in this embodiment, the pot lid component 1 includes a pot lid liner 16 . The pot cover 14 is arranged on the below of the pot cover lining 16 in a suspension mode, so that it can move up and down. Under this setting condition, only the pot cover 14 moves upwards under the effect of the pressure in the pot, and other parts of the pot cover part 1 are relatively fixed. The force transmission part 6 in the pressure control mechanism is arranged on the upper surface of the pot cover 14 or is made integral with it. The pot cover 14 can be suspended below the pot cover liner 16 through the elastic element 18 . The elastic force of the elastic element 18 is related to the pressure value in the pot. The contact of the switch 5 is arranged on the position corresponding to the force transmission member 6 on the lid lining 16 . The setting of pressure control mechanism, and the connecting condition with other parts should satisfy: when pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com