Method for preventing optical feedback of semiconductor laser processing machine

A laser processing machine and laser processing technology, applied in the direction of semiconductor laser devices, laser devices, laser welding equipment, etc., can solve problems such as damage, shortened life, and decreased output power of lasers, so as to reduce damage, prevent life reduction, and output light Effect of Power Density Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

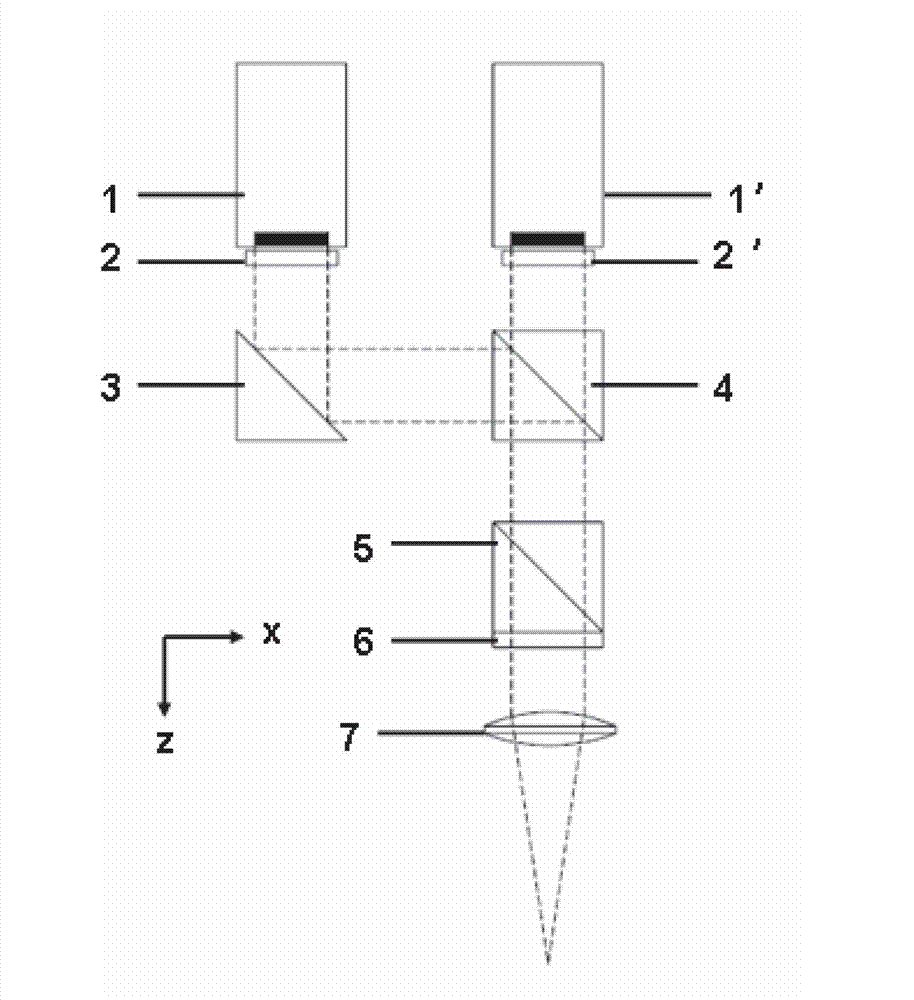

[0024] The inventive idea of the present invention is: a method for preventing optical feedback of a semiconductor laser processing machine. The stack respectively emits a wavelength of λ 1 and lambda 2 P or S polarization state of the laser beam. The method for preventing optical feedback of semiconductor laser processing machine of the present invention is to utilize:

[0025] A reflective prism that is set at 45° to the optical path is arranged before one of the semiconductor laser stacks; the other semiconductor laser is set in turn before the stack, and a wavelength beam combining prism and a polarization beam splitter are set at 45° with the optical path, and A quarter-wave plate and a focusing mirror set perpendicular to the optical path;

[0026] The light emitted by one of the semiconductor laser stacks passes through the reflective prism, and the propagation direction is rotated by 90°; the light emitted by the other semiconductor laser stack is directly inciden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap