Electroplating clamp

A technology of electroplating fixtures and chucks, applied in electrical components, electrolysis process, electrolysis components, etc., can solve the problems of electroplating liquid barrel damage, copper particles sticking in, bottom collision, etc., to prolong the service life and have strong corrosion resistance. , The effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

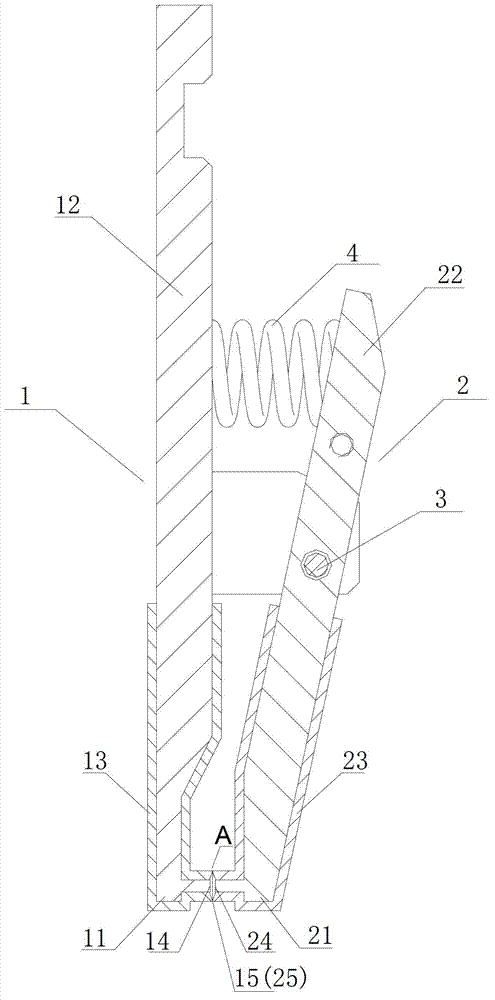

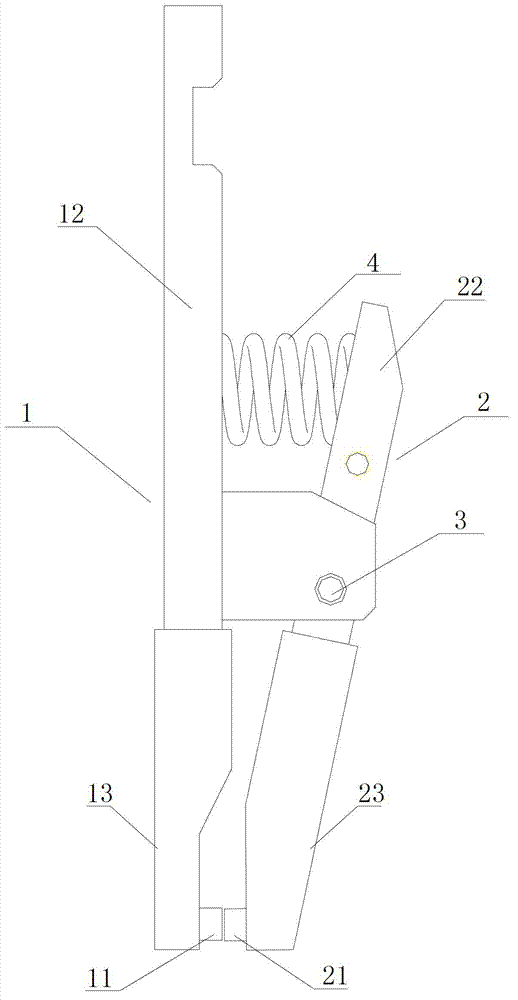

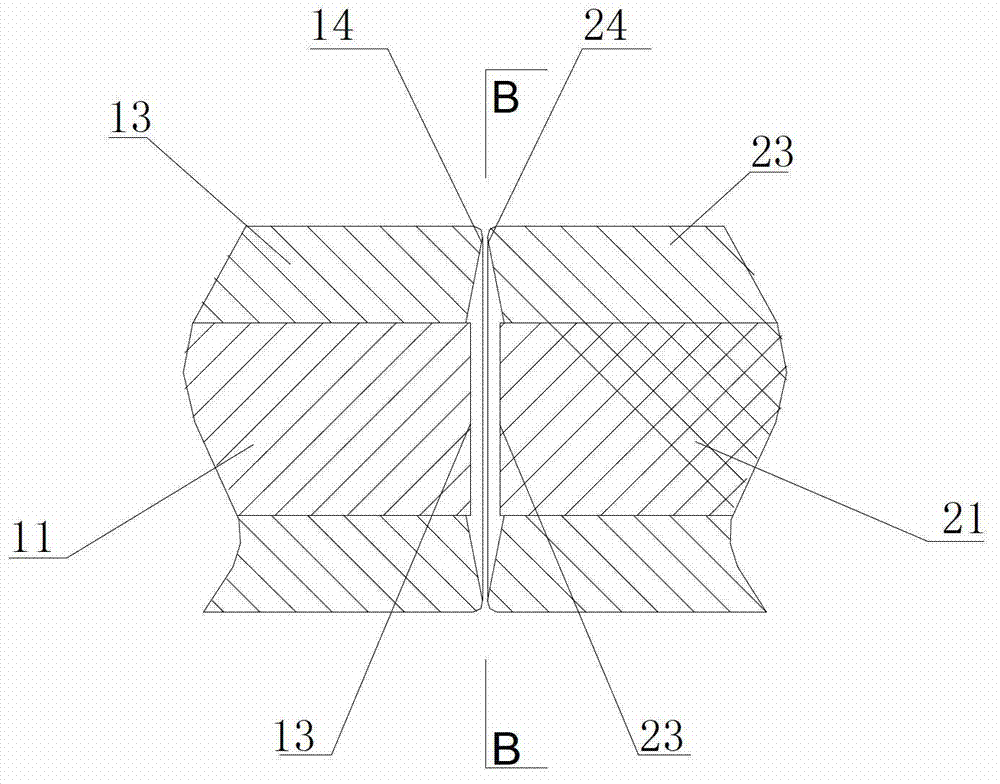

[0023] like figure 1 , figure 2 , image 3 and Figure 4 As shown, an electroplating fixture includes a main clamp 1 and a sub-clamp 2 integrated by a pin shaft 3, a main and sub-clamp head 11, 21 opposite to each other at the front end, and a main and sub-clamp handle 12, 22 opposite to each other at the rear end. , elastic element 4 is arranged between the main and auxiliary chuck handles 12, 22 to clamp the main and auxiliary chucks 11, 21. Electrode conduction contact surfaces 14 , 24 are formed therebetween, and insulating jackets 13 , 23 around the ring electrode conduction contact surfaces 14 , 24 form relative clamping ring edges 15 , 25 .

[0024] The electrode conduction contact surfaces 14, 24 are planes, and the clamping rings 15, 25 slightly protrude from the electrode conduction contact surfaces 14, 24.

[0025] The main and auxiliary chucks 11 and 21 are provided with opposite conductive nail bodies, and the conductive nails are plane contact surfaces for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com