Diagnosis method for low-frequency fluid vibration excitation failure of compressor based on axial vibration analysis

An axial vibration and fault diagnosis technology, which is applied to machines/engines, mechanical equipment, liquid variable capacity machinery, etc., and can solve problems such as the inability to perform quantitative monitoring and tracking, and the inability to accurately classify fault frequencies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

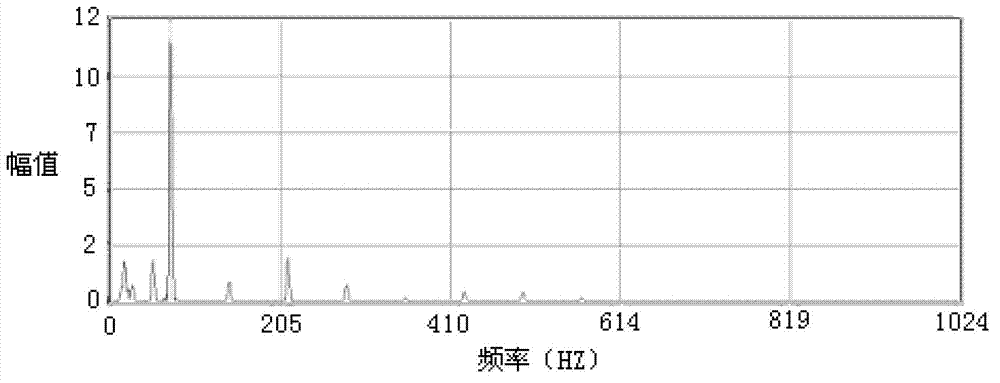

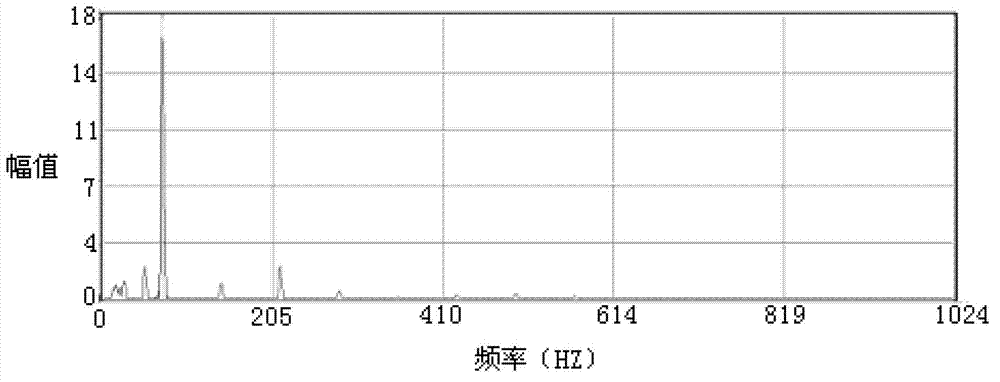

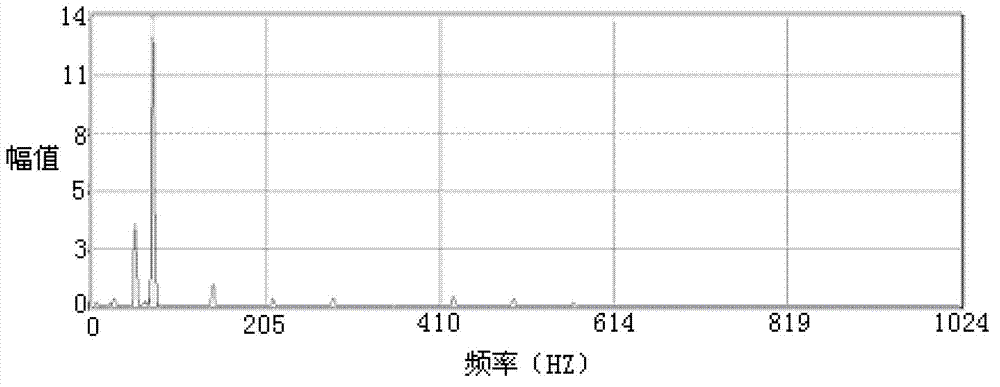

[0047] The present invention introduces axial low-frequency (frequency between 0 and rotation frequency) vibration signal analysis technology, adopts spectrum refinement analysis on the dynamic AC part in the axial vibration signal, and accurately identifies, diagnoses, and diagnoses low-frequency fluid-excited vibration faults. Quantitative tracking and monitoring.

[0048] First of all, in order to make the obtained vibration signal more clearly show the low-frequency fault of the compressor, the coherence between it and the change of the DC signal is investigated, the influence of the axial movement signal on the vibration signal is eliminated, and the obtained axial vibration AC Part of the signal is transformed by FFT, and the characteristic spectral line interpolation technology is used to obtain accurate amplitude, frequency and phase, and make an accurate spectrum to better highlight the actual vibration characteristics of low-frequency fluid excitation fault signals. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com