The method of directing the production of polishing powder and the quality control of products by electric conductivity

A technology of product quality and electrical conductivity, applied in the direction of material resistance, can solve problems such as research content and methods that have not been reported, and achieve the effect of stable polishing quality and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

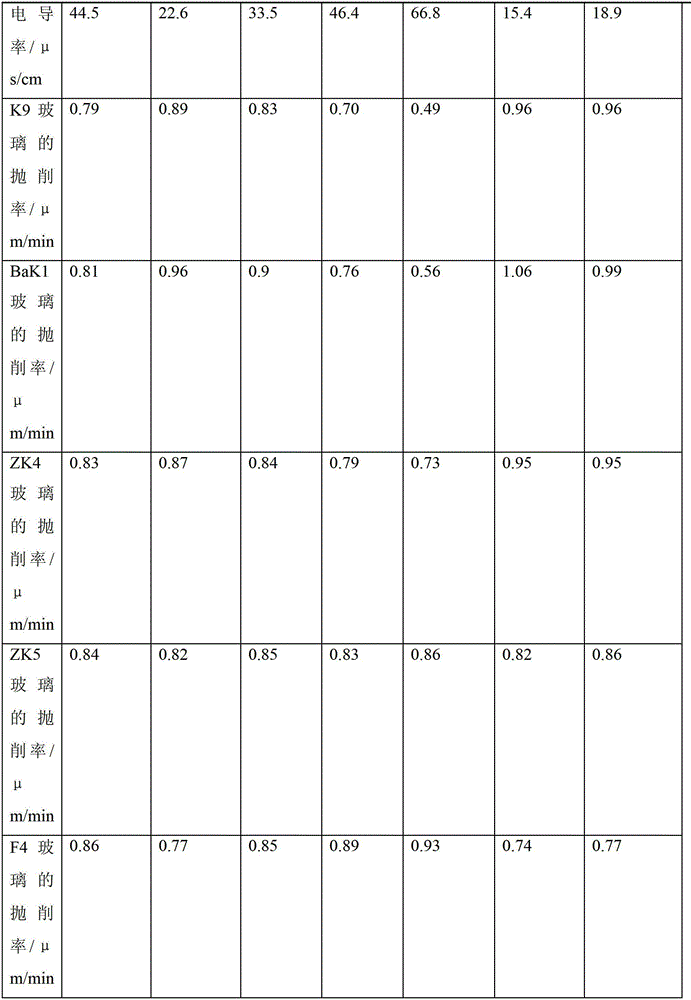

[0018] Take polishing powder samples LCF-A116, LCF-A1171, LCF-A01, LCF-A06, LCF-A106, LCF-A01L, LCF-A151 for corresponding detection, followed by the following steps:

[0019] (1) Pre-dry at 150°C for 30 minutes, weigh 10 grams, add it to a 100mL graduated cylinder, add pure water to 100mL, cover it, and oscillate to fully disperse the polishing powder.

[0020] (2) After standing still for 5 minutes, oscillate again to fully combine the active centers in the polishing powder with water, and then measure the conductivity immediately.

[0021] (3) Carry out the removal rate experiment on the above samples respectively. See the table below for the results:

[0022] Table 1. Comparison of electrical conductivity and removal rate of different samples

[0023]

[0024]

[0025] In the above table, the abrasion hardness of K9 glass is 100, the abrasion hardness of BaK1 is 80, the abrasion hardness of ZK4 is 79, the abrasion hardness of ZK5 is 71, and the abrasion hardness of...

Embodiment 2

[0027] Take the polishing powder sample LCF-A116 of different batches of the same brand for corresponding testing, and follow the steps in turn:

[0028] (1) Pre-dry at 150°C for 30 minutes, weigh 10 grams, add it to a 100mL graduated cylinder, add pure water to 100mL, cover it, and oscillate to fully disperse the polishing powder.

[0029] (2) After standing still for 5 minutes, oscillate again to fully combine the active centers in the polishing powder with water, and then measure the conductivity immediately.

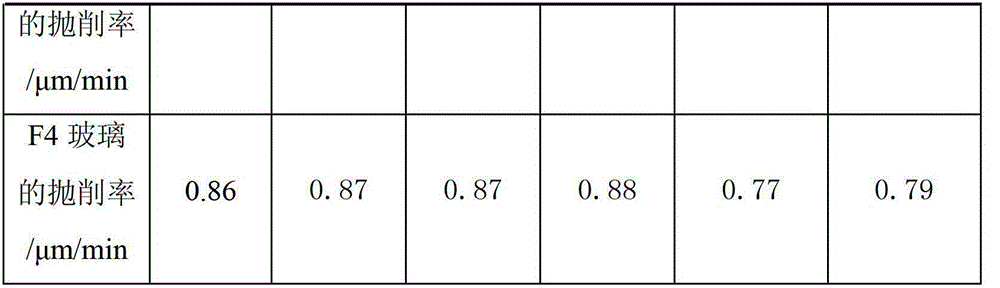

[0030] (3) Carry out the removal rate experiment on the above samples respectively. See the table below for the results:

[0031]

[0032]

[0033] It can be seen from the above table that the difference in conductivity of the four batches of LCF-A116 polishing powder 12-06-1, 12-06-5, 12-06-8, and 12-06-9 is less than 5μs / cm, The difference in the removal rate of the same type of glass does not exceed 0.02 μm / min; when the difference in electrical conductivi...

Embodiment 3

[0035] Take the polishing powder sample LCF-A1171 of different batches of the same brand for corresponding testing, and follow the steps in turn:

[0036] (1) Pre-dry at 150°C for 30 minutes, weigh 10 grams, add it to a 100mL graduated cylinder, add pure water to 100mL, cover it, and oscillate to fully disperse the polishing powder.

[0037] (2) After standing still for 5 minutes, oscillate again to fully combine the active centers in the polishing powder with water, and then measure the conductivity immediately.

[0038] (3) Carry out the removal rate experiment on the above samples respectively. See the table below for the results:

[0039]

[0040]

[0041] From the above table, it can be found that the difference in conductivity of the four batches of LCF-A1171 polishing powder 12-08-119, 12-08-126, 12-08-132, and 12-08-146 is less than 5μs / cm, The difference in the removal rate of the same type of glass is not more than 0.02 μm / min; when the difference between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com