Modeling approach for shipbuilding enterprise subsection workshop spatial scheduling model based on cellular machine

A modeling method and space scheduling technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that the space scheduling technology of the segmented workshop cannot take into account the simplicity and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

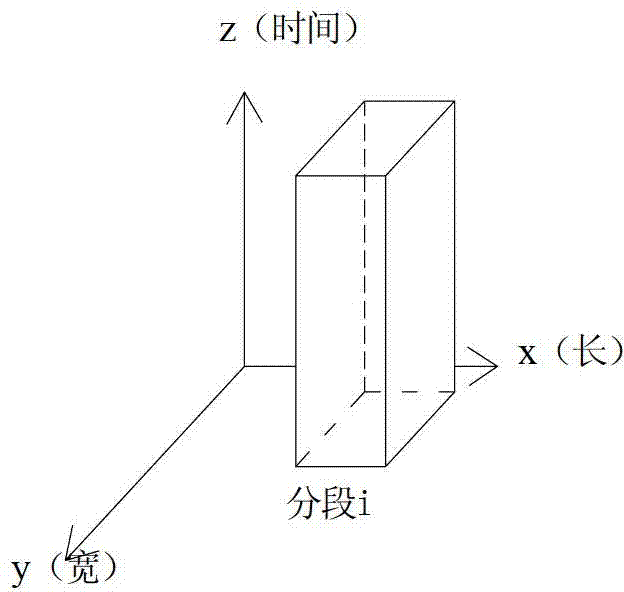

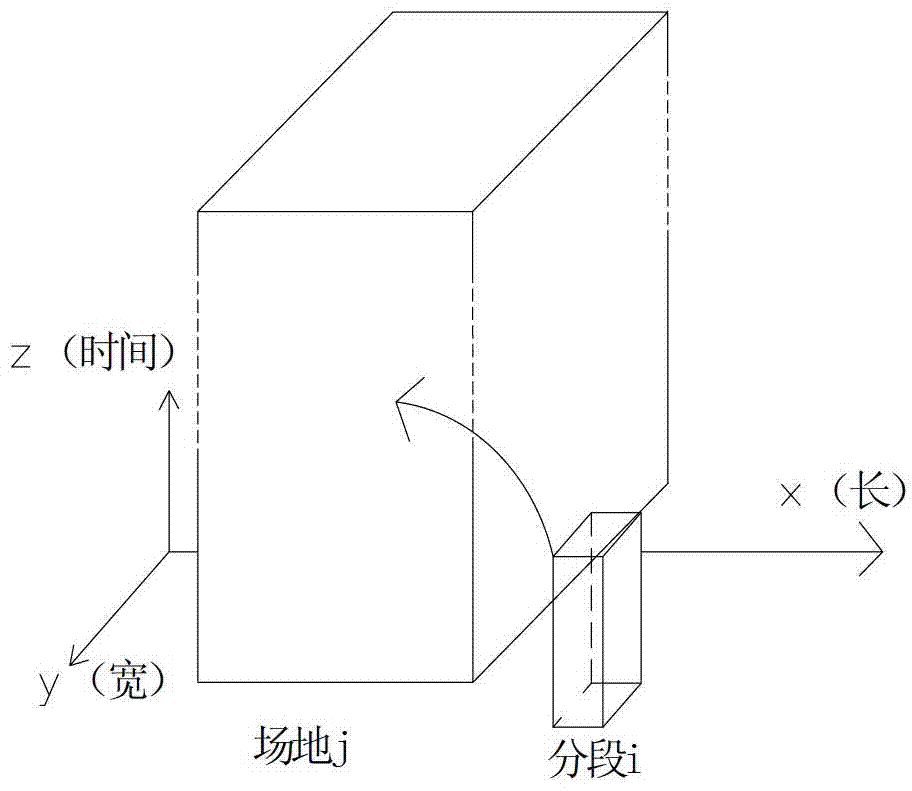

Method used

Image

Examples

example

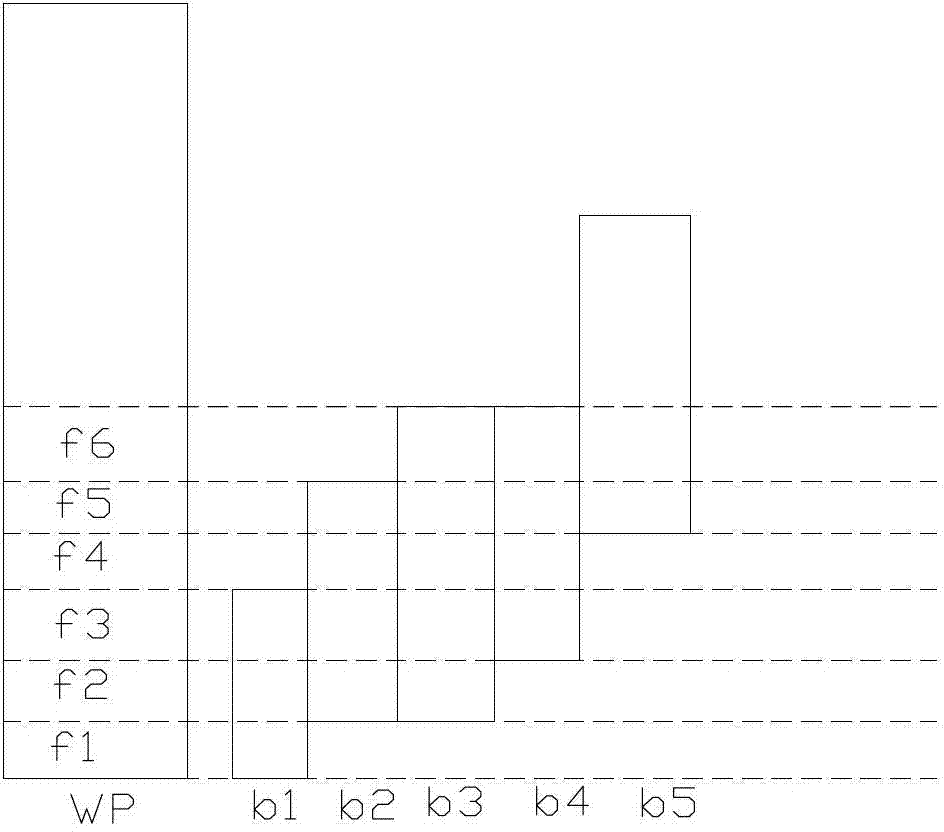

[0161] Example: Research on the segment space scheduling problem of the company's segmented workshops, and select the company's segmented production plan in August 2011 to verify the validity of the model. The plan includes two main ship types: 2173 and 2087, including all the basic data information of each segment in the plan. In the example, there are a total of 96 segments (including the arranged segments), and 3 corresponding layout sites (Site 1, Site 2 and Site 3). In view of the large amount of content and information involved in the examples. At the same time, the scheduling simulation process of each site is the same, and the scheduling principle of each floor in the same site is the same, so the first floor of the more typical site 3 can be selected as an example for specific simulation, and other site simulations are taken as an example . Data input is carried out according to the basic data of the section already arranged (Table 1), the basic data of the section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com