Modulation ring rotor based on magnetic shielding principle

A modulation ring, principle technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., to achieve the effect of high mechanical strength, high mechanical strength and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

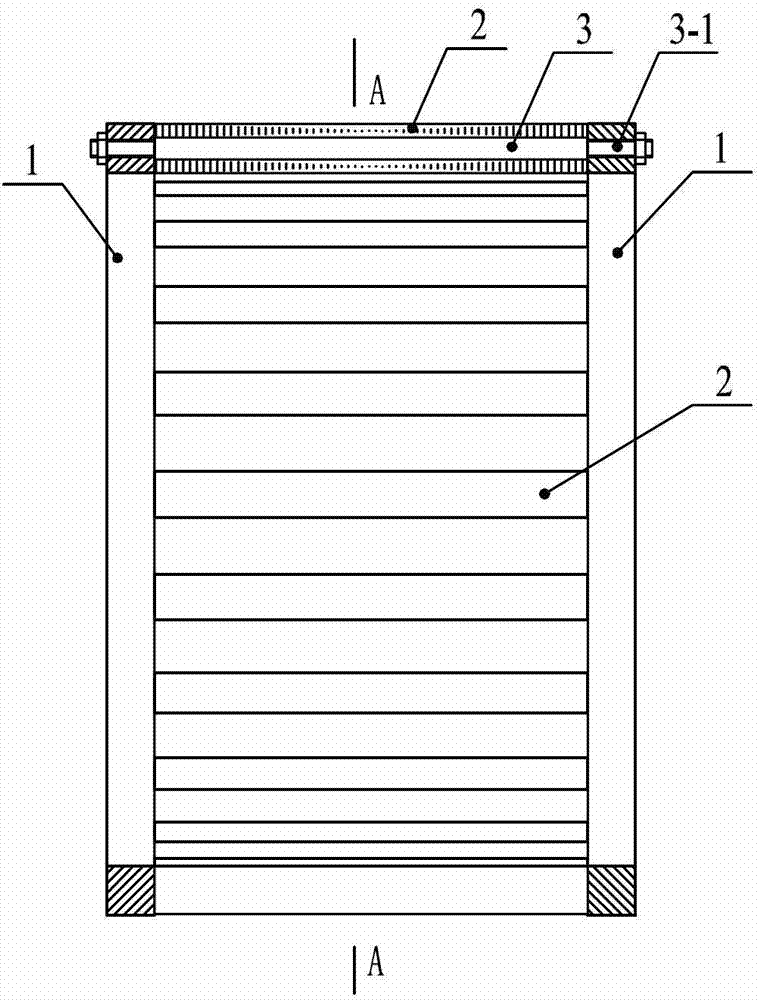

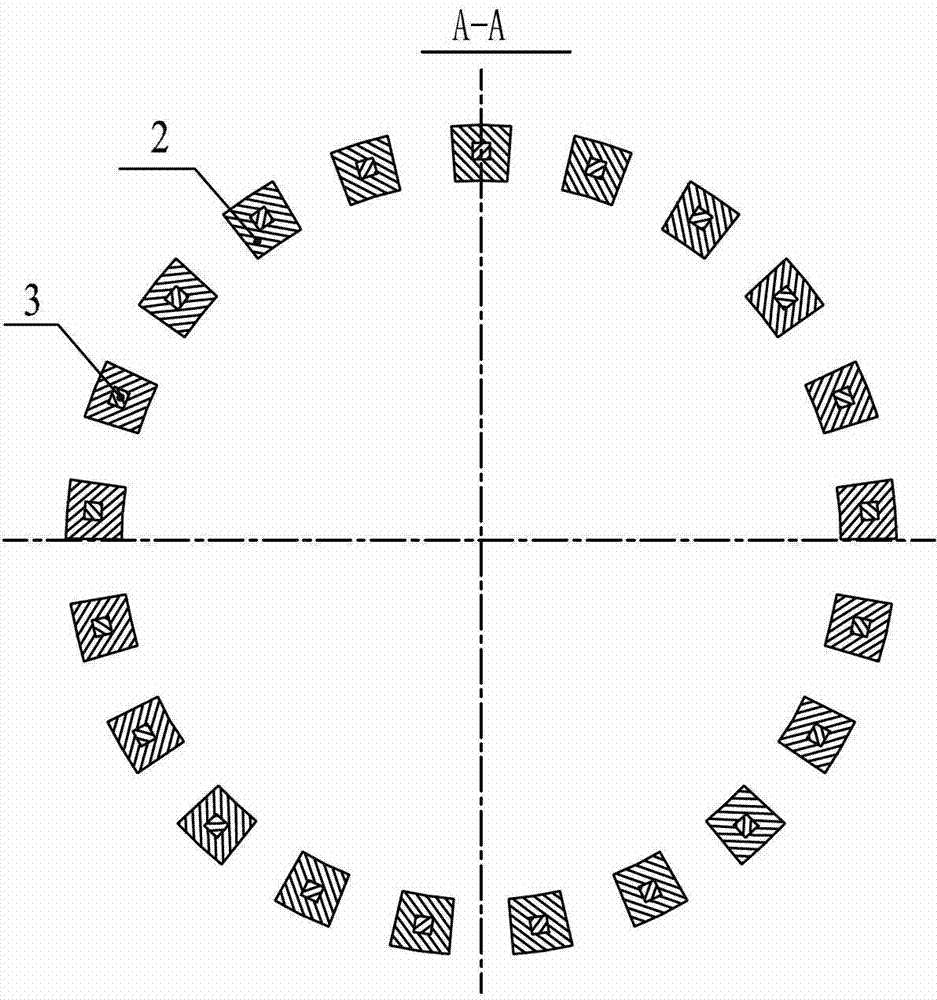

[0036] Specific implementation mode one: the following combination Figure 1 to Figure 7 Describe this embodiment, the modulation ring rotor based on the magnetic field shielding principle described in this embodiment, it includes two end rings 1, n magnetic conductive blocks 2 and n connecting rods 3,

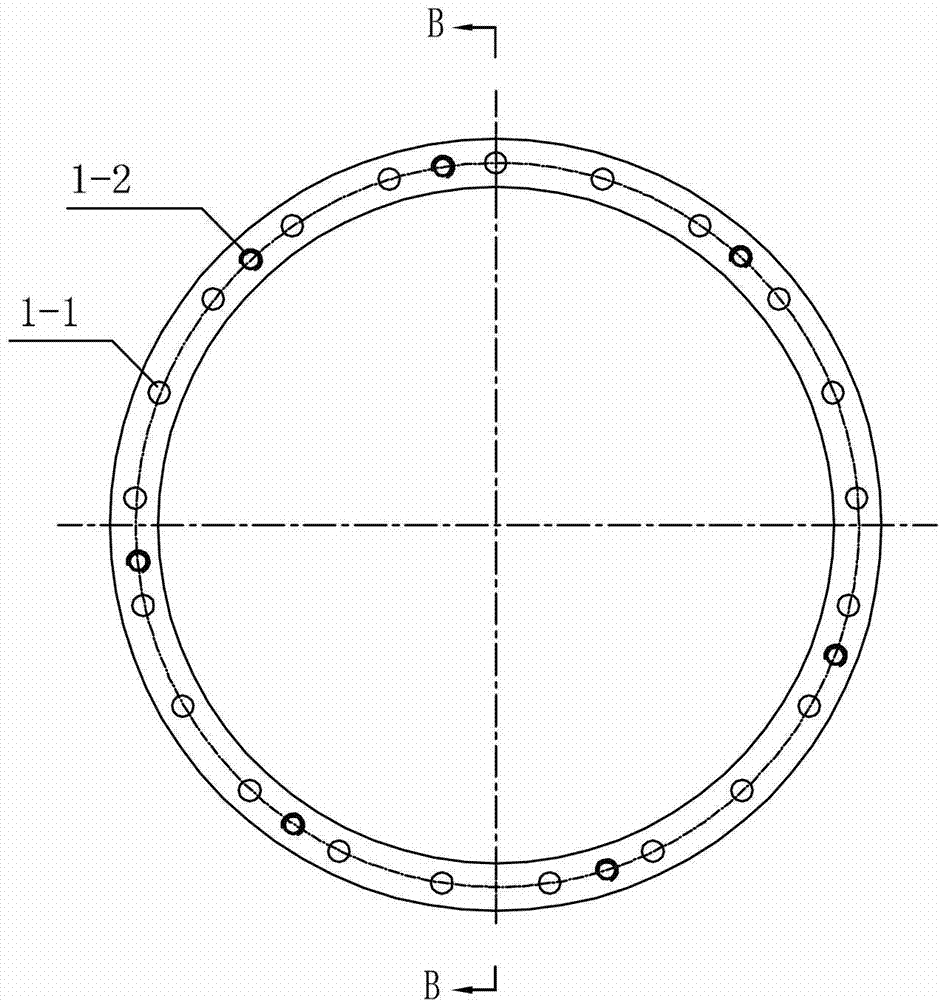

[0037] A plurality of through holes 1-1 are evenly arranged on the end surface of the end ring 1 along the circumferential direction, and a plurality of screw holes 1-2 are evenly arranged on one end surface of the end ring 1,

[0038] The two end rings 1 are arranged in parallel, and the screw holes of the end rings 1 are arranged opposite to each other, the positions of the through holes 1-1 in the two end rings 1 are opposite to each other, and n magnetic blocks are arranged between the two end rings 1 2. Each magnetic block 2 is fixed together with two end rings 1 by a connecting rod 3,

[0039] A cylindrical screw 3-1 is arranged at both ends of the shaft of the connecti...

specific Embodiment approach 2

[0048] Specific implementation mode two: the following combination Figure 8 and Figure 9 This embodiment will be described, and this embodiment will further describe the first embodiment, which also includes a strap 4, which is wound and fixed on the outer circular surface of the modulation ring rotor.

[0049] Bandage 4 is realized by glass fiber cloth tube. The modulating ring rotor of this embodiment has better mechanical reliability.

specific Embodiment approach 3

[0050] Specific implementation mode three: the following combination Figure 10 and Figure 11 This embodiment will be described. This embodiment will further describe the first embodiment, which also includes epoxy resin 5 , and the epoxy resin 5 fills the gap between the end ring 1 and the magnetic block 2 .

[0051] exist Figure 10 The air part in the middle modulation ring rotor is poured with epoxy resin to form a Figure 11 The modulating ring rotor in. The modulation ring rotor in this embodiment has higher mechanical reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com