Clutching type traction motor

A traction motor and clutch-type technology, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve problems such as increased fuel consumption, inconvenient charging, and short mileage, and achieve reliable operation, convenient use, The effect of low manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

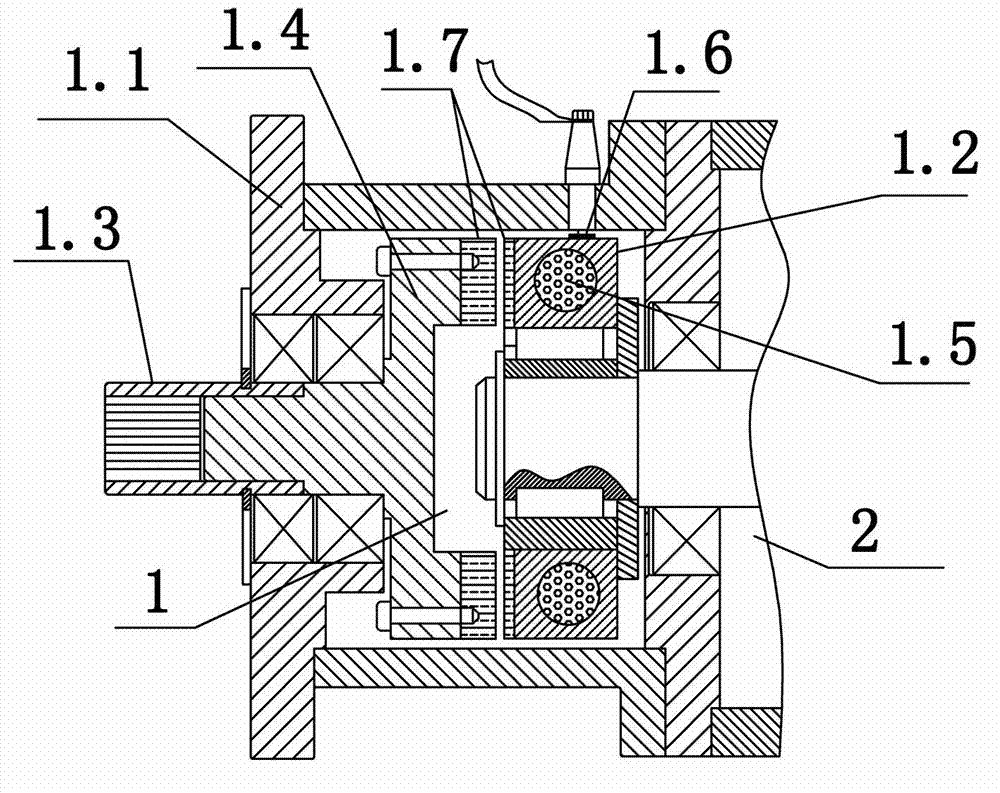

[0014] Attached below figure 1 The specific implementation of the clutch-type traction motor of the present invention will be described in detail below.

[0015] As attached figure 1 The clutch type traction motor shown includes an electromagnetic clutch 1 and a motor 2 that are fixedly connected together. The electromagnetic clutch 1 includes a housing 1.1 fixedly connected to the motor 2 and an active part 1.2 fixedly connected to the shaft of the motor 2. The output shaft 1.3 and the follower 1.4 which is axially slidable with the output shaft 1.3 and can be magnetically attracted to the driving part 1.2, the contact surfaces of the driving part 1.2 and the driven part 1.4 are fixed with wear plates 1.7 and the driving part 1.2. An excitation coil 1.5 is arranged inside, and the excitation coil 1.5 is connected in parallel with the coil assembly of the motor 2 in the same power supply line through a brush 1.6 arranged on the housing 1.1, and the output shaft 1.3 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com