A magnetic speed governor capable of automatic speed change and its speed regulating method

An automatic speed change and automatic speed regulation technology, which is applied in the direction of electric components, electromechanical transmission devices, electrical components, etc., can solve the problems of large error, slow start, small torque of magnetic speed governor, etc., and achieve overload protection performance and starting performance Good, improve stability and durability, avoid the effect of vibration interference

Inactive Publication Date: 2016-04-27

JIANGSU UNIV

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

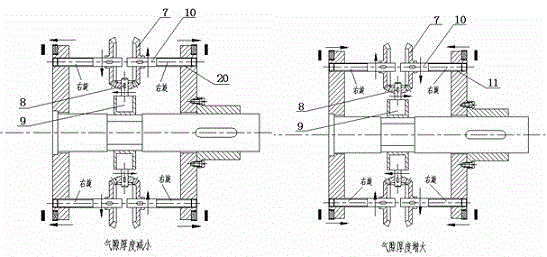

[0002] With the development of magnetic machinery, asynchronous magnetic governors are more and more widely used in oil refining, chemical industry and other industries. As a structure of magnetic machinery, asynchronous magnetic governors are more important than traditional mechanical couplings. During the transmission process, there is no mechanical contact, friction and wear, which realizes non-contact torque transmission and reduces the mechanical loss of transmission components. Therefore, in some areas of large torque vibration, magnetic governors have gradually replaced mechanical couplings. However, on the one hand, ordinary asynchronous magnetic speed governors cannot automatically adjust the gap between the input device and the output device, so there is no overload protection function during the work process, so it cannot solve the problem when the motor load starts. On the other hand, the ordinary asynchronous magnetic speed governor can only rely on the rotation of the permanent magnet magnetic field to generate torque transmission motion. Therefore, when the motor starts, the rotating magnetic field speed of the permanent magnet gradually increases, and the magnetic speed The torque is small, the start is slow, and the variable speed function and the low-speed high-torque start cannot be realized; therefore, how to realize the automatic variable speed of the asynchronous magnetic speed controller and the soft start of the motor, effectively solve the problem of motor heating and failure when the motor load starts , Improving the transmission performance of the magnetic speed governor and meeting the special working conditions with specific requirements for the load speed is one of the key issues to expand the application range of the magnetic speed governor

[0003] In the patent 200910263064.X, an adjustable magnetic induction coupling is disclosed, including: a driving disc assembly, a driven disc assembly and a speed regulating mechanism, which changes the axial movement of the driven disc so that the main and driven discs The thickness of the air gap between them changes, so as to change the size of the output torque, but this kind of magnetic coupling is not convenient to operate through manual adjustment, the adjustment accuracy is not high, the error is large, and the transmission performance is not high; in the patent 201010228656.0 , discloses a remote automatic control speed-adjustable disc magnetic coupling, including: a drive disc assembly, a driven disc assembly and a speed regulating device assembly, and the driving and driven discs are also driven by the speed regulating device The thickness of the air gap between them changes, so as to change the size of the output torque. Although this kind of magnetic coupling can automatically adjust the length of the air gap, there is no specific description for the power supply structure of the micro motor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0025] The working principle of embodiment 2: on the basis of embodiment 1, the copper block 5 in the driven plate assembly ② is replaced by the copper plate 21 cast on the yoke, and its working principle is the same as that of embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

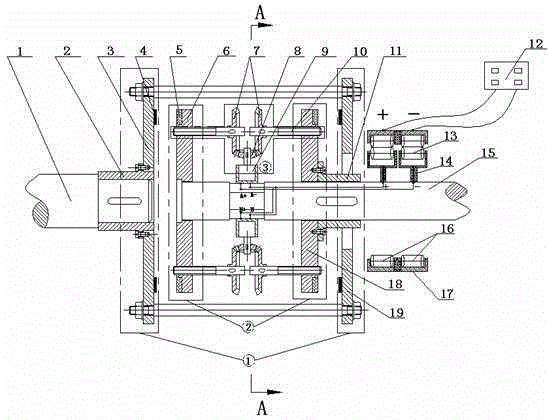

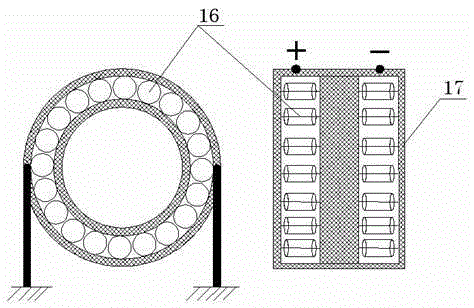

Login to View More Abstract

The invention relates to the technical field of mechanical engineering transmission, particularly to a magnetic governor with automatic transmission ability and mainly used for transmission of power between a motor and a load in industries such as oil refining, chemicals, coal and power generation and for other devices. The magnetic governor is composed of a driving disc assembly, a driven disc assembly and an automatic speed regulation device assembly, wherein the driving disc assembly (1) is composed of a driving disc base I, a driving disc base and a permanent magnet; the driven disc assembly is composed of a driven disc base I, a driven disc base and a copper block; the automatic speed regulation device assembly presents symmetrical distribution along the axis and mainly comprises a micro motor, a single-start thread screw rod and an actiyator. The actiyator controls the micro motor to rotate, the driven disc base I and the driven disc base are enabled to perform opposite or contrary movement axially through gear drive and thread transmission, therefore the air gas thickness between the driven disc and the driving disc is changed, stepless automatic speed change is achieved through magnetic field coupling, and the application range of the magnetic governor is further extended.

Description

technical field [0001] The invention relates to the technical field of mechanical engineering transmission, in particular to a magnetic speed governor capable of automatic speed change, which is mainly used in power transmission systems between motors and loads in industries such as oil refining, chemical industry, coal, and power generation. Background technique [0002] With the development of magnetic machinery, asynchronous magnetic governors are more and more widely used in oil refining, chemical industry and other industries. As a structure of magnetic machinery, asynchronous magnetic governors are more important than traditional mechanical couplings. During the transmission process, there is no mechanical contact, friction and wear, which realizes non-contact torque transmission and reduces the mechanical loss of transmission components. Therefore, in some areas of large torque vibration, magnetic governors have gradually replaced mechanical couplings. However, on the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02K51/00

Inventor 杨超君周曰华蒋毅一孔令营

Owner JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com