A processing method for exposing a circuit board by using a dust-proof support frame

A processing method and circuit board technology, which are used in microlithography exposure equipment, photolithographic process exposure devices, printed circuits, etc. Debris, expensive equipment and other problems, to achieve the effect of reducing hidden dangers of scratches, avoiding circuit defects, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

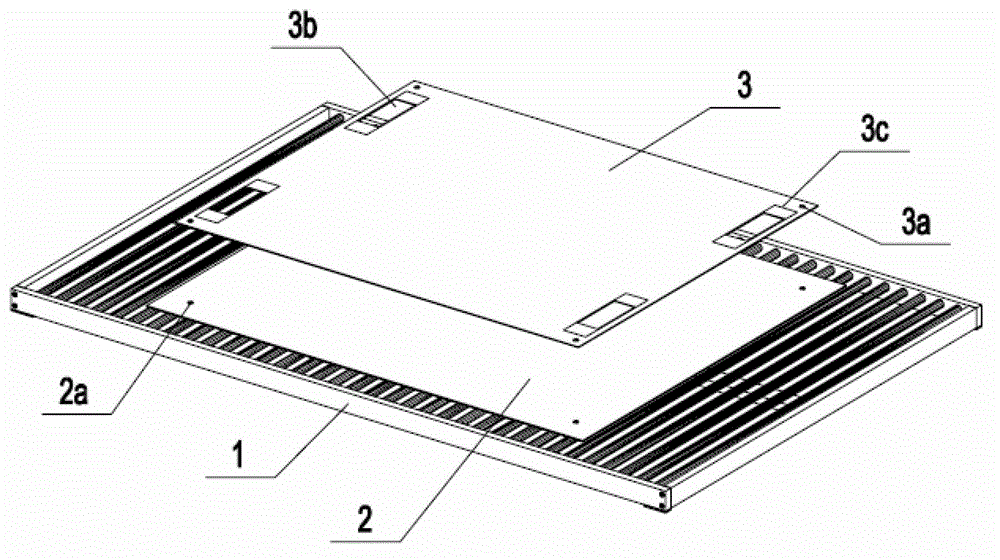

[0019] Such as figure 1 with figure 2 Shown is a processing method for exposing a circuit board by hand using a dust-proof support frame, which includes manual alignment of the circuit board, and also includes the following steps: circuit board preparation→circuit board single-sided film alignment→check the alignment effect→ Flip the circuit board → align the film on the other side of the circuit board → check the alignment effect → expose; the details are as follows:

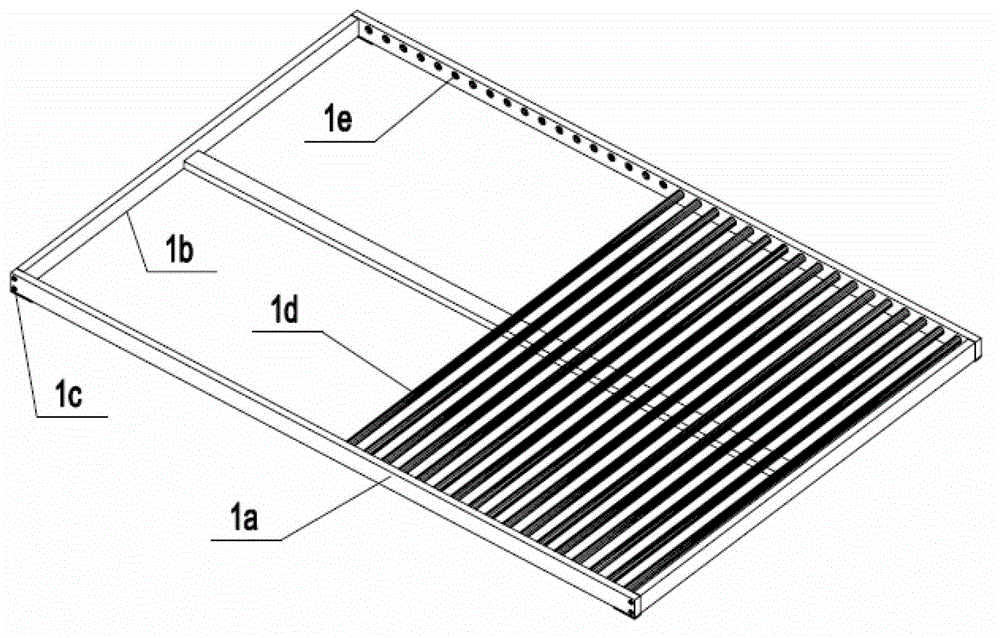

[0020] 1) Circuit board preparation: the circuit board 2 is placed on the dust-proof support frame 1 on the alignment table after pasting film or solder mask;

[0021] 2) Use the prepared corresponding surface film 3, and manually align the four alignment rings 3a of the film with the four alignment holes 2a of the circuit board; the alignment rings 3a overlap with the alignment holes 2a after alignment; the After the film 3 is aligned, use the positioning tape 3c pasted on the film 3 in advance to paste and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com