Manufacturing method of coupler knuckle

A manufacturing method and knuckle technology, which is applied in the field of rail vehicles, can solve problems such as driving safety hazards, accelerated knuckle wear, and inability to effectively guarantee quality, so as to achieve the effect of improving service life and ensuring internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiment of the present invention provides a method for manufacturing a hook knuckle. The method includes the following steps:

[0026] 1) Blanks are cut from raw materials; the raw materials can be round steel or steel plates; the shape of the raw materials is square or cylindrical;

[0027] 2) One heating, heating the blank once; preparing for the next free forging;

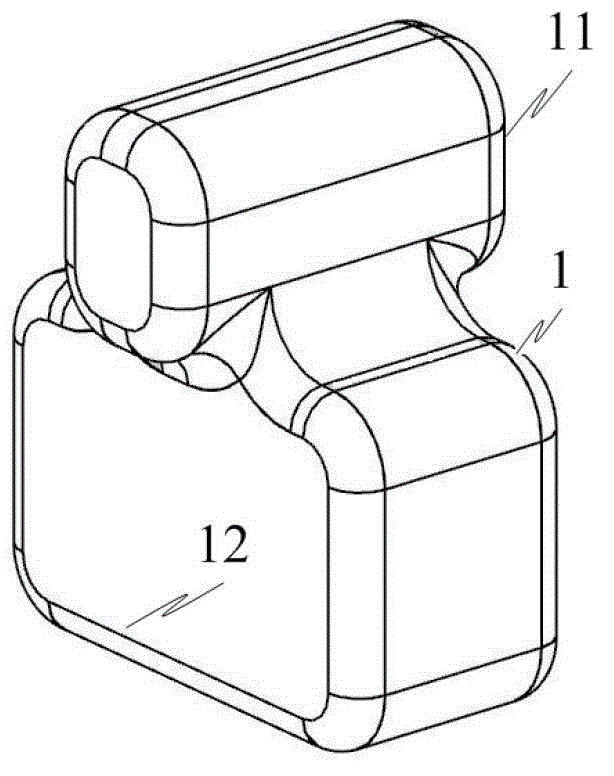

[0028] 3) Free forging, free forging the blank; the shape of the free forging blank 1 is as figure 1 As shown; it is necessary to forge the shape of the free forging blank 1 based on the raw material blanks. The cross-sectional area of the head 11 and the tail 12 of the free forging blank 1 changes greatly, so it is easy to occur in the process Cracks and folds;

[0029] 4) Reheating: reheat the blanks after free forging; prepare for the first die forging;

[0030] 5) For one-time forging, the blank after the second heating is placed in a forging die for one-time forging;

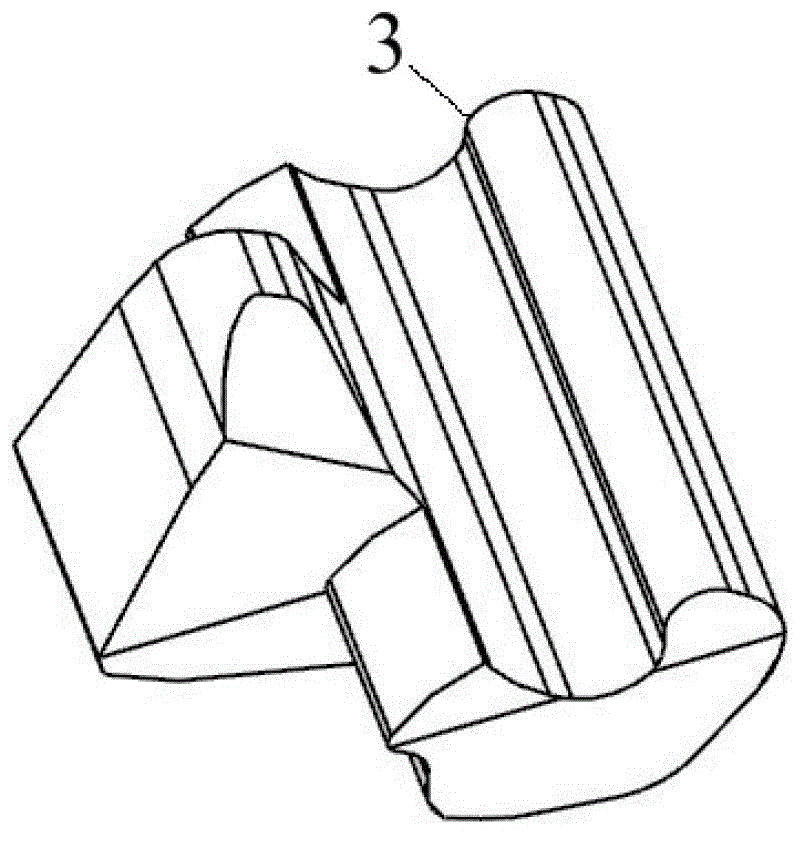

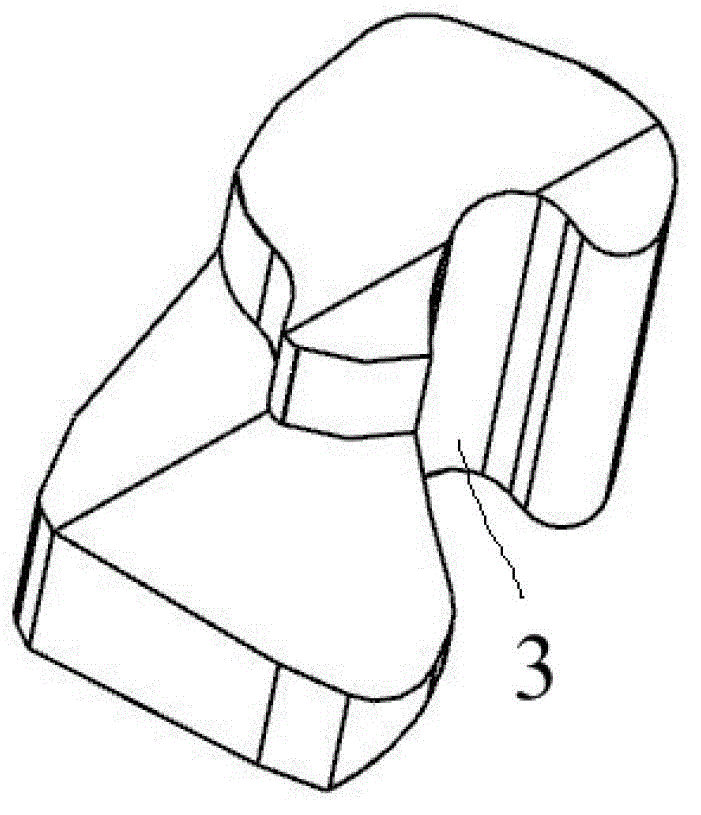

[0031] The shape of the blank fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com