Hot ladle spheroidizing process

A treatment process and spheroidization technology, which is applied in the improvement of process efficiency, manufacturing tools, metal processing equipment, etc., can solve the problems of poor spheroidization, excessive melting, low density of ferrosilicon perlite, etc. Slag problem, effect of delaying spheroidization initiation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

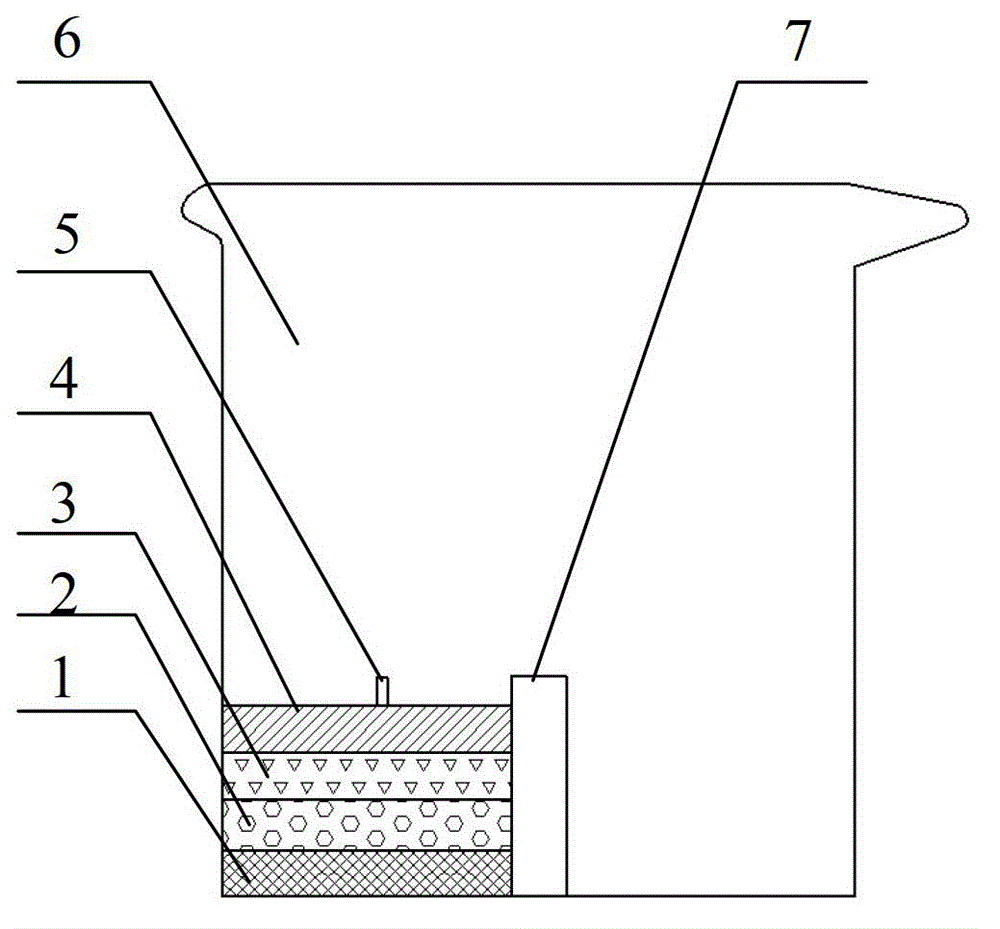

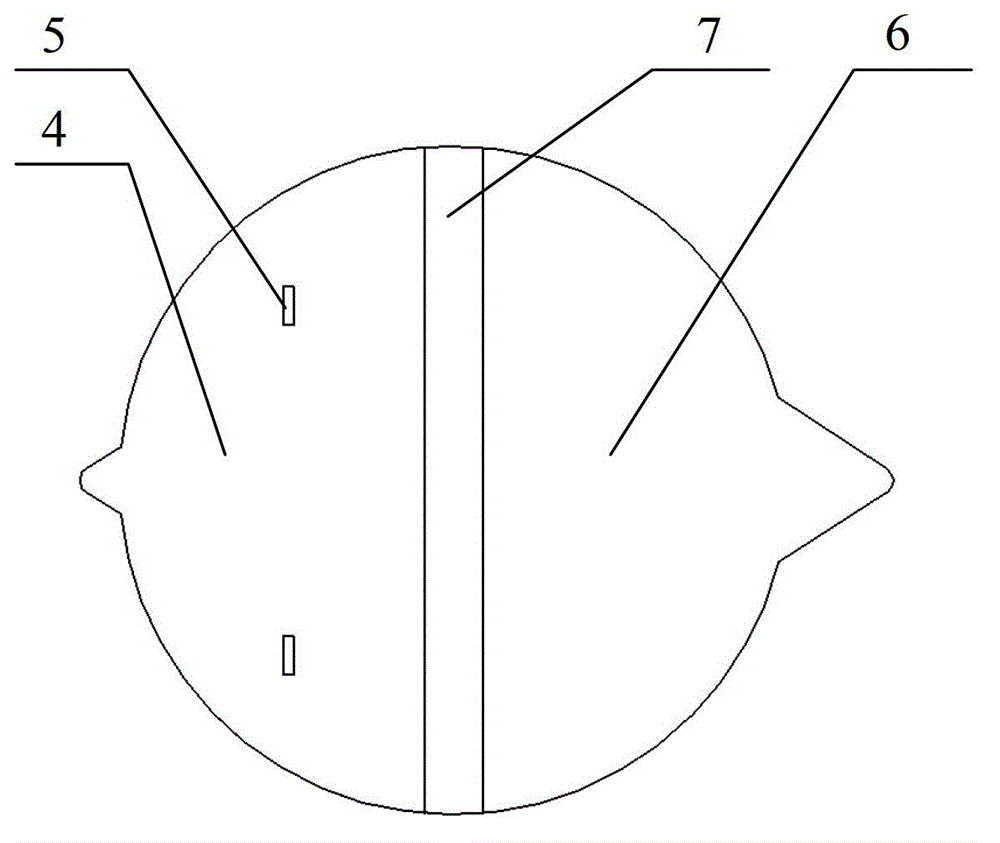

[0021] combine figure 1 with figure 2 , the hot ladle spheroidization treatment process of the present invention, first use the original molten iron to scald the ladle 6 within 30 minutes before tapping, so that it reaches a red hot state before embedding the ladle; then the operator puts the spheroidizer on the outside of the ladle 1. Ferrosilicon particles 2 and steel chips 3 are poured into one side of the dam 7 in the bag in sequence, and are flattened and compacted layer by layer with tools; The molten iron cast iron cover plate 4 is hoisted and placed on the compacted layer. The thickness of the original molten iron cast iron cover plate can be selected in the range of 5-30mm according to the size of the ladle; finally pour molten iron into the ladle to complete the hot ladle spheroidization treatment process, the temperature of molten iron after spheroidizing trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com