Bellows girth welding machine

A technology of circular seam welding and bellows, which is applied in the field of automobile exhaust catalytic purifier manufacturing equipment, can solve the problems of dislocation of bellows and other metal parts, high risk, increased rework tasks, etc., and achieves simple welding operations and automation. High, improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

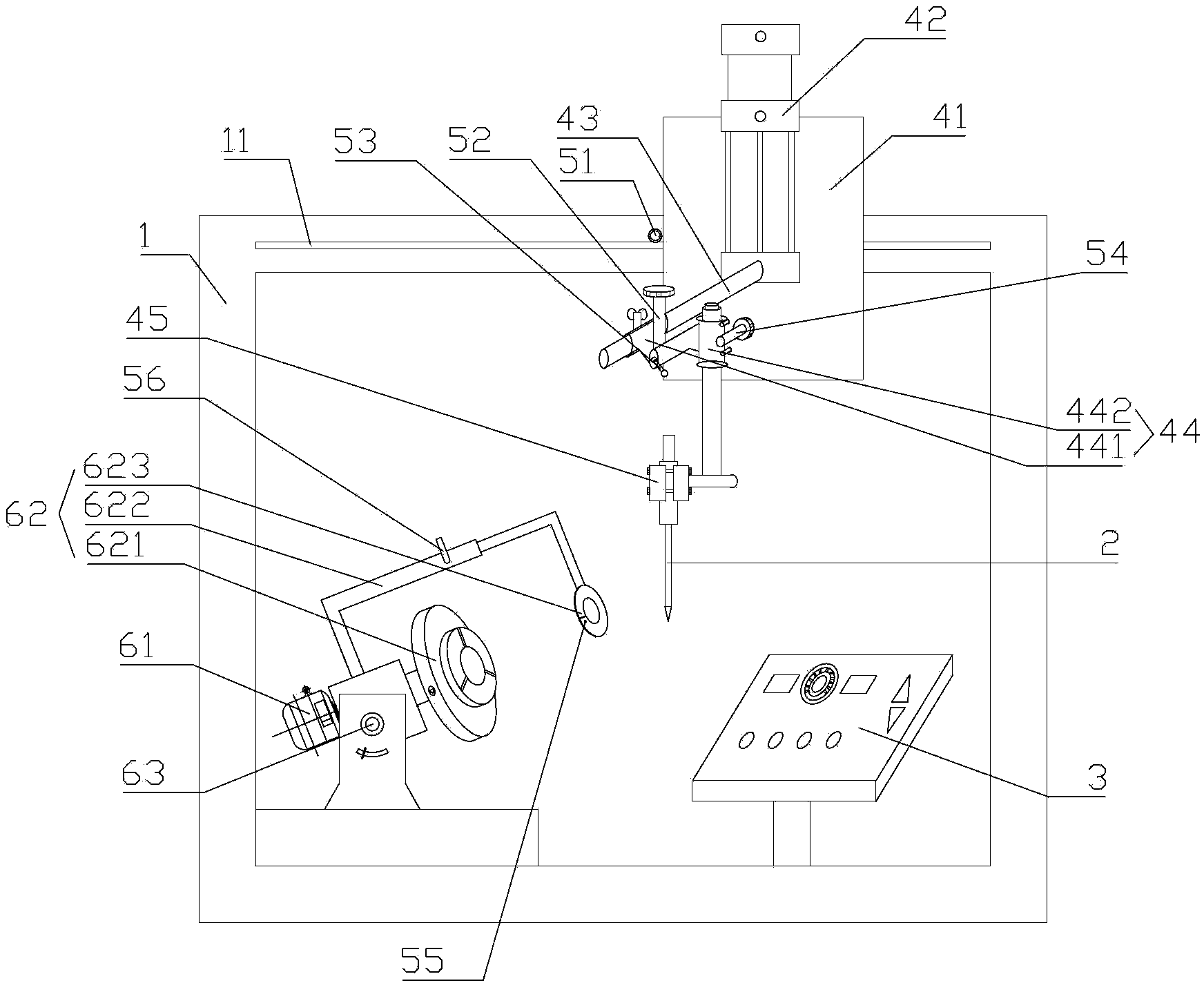

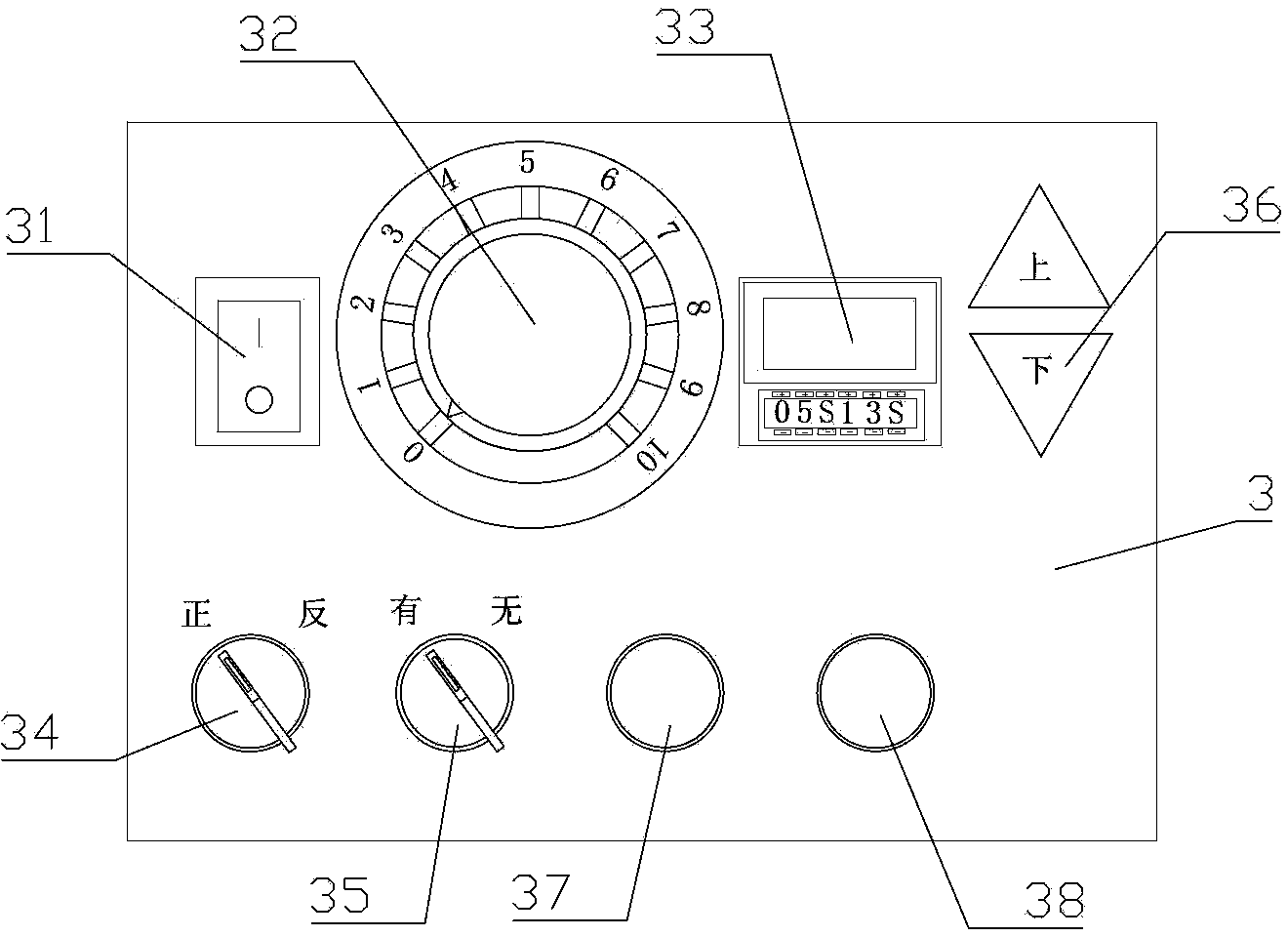

[0018] Such as figure 1 and figure 2 As shown, the bellows girth welding machine includes a bracket 1, a welding torch moving mechanism connected to the upper part of the bracket to drive the welding torch 2 to move, and a weldment rotating mechanism connected to the lower part of the bracket to drive the weldment to rotate, and the welding torch moving mechanism The relative bracket moves to adjust the welding position, and the weldment rotation mechanism drives the weldment to rotate continuously during the welding process so that the solder forms an annular weld on the weldment.

[0019] The welding torch moving mechanism includes a movable plate 41 which can move horizontally on the support, a cylinder 42 which is arranged on the movable plate, a moving shaft 43 which is fixed on the lower end of the piston rod of the cylinder, and which can move forward and backward while being sleeved on the moving shaft. The welding torch clamp sleeve 44 that the moving shaft rotates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com