Preparation method of graphene roll

A graphene roll and graphene technology, applied in the field of graphene, can solve the problems of violent reaction, low yield and high cost, and achieve the effect of simple operation, mild reaction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] The invention provides a kind of preparation method of graphene roll, comprising:

[0023] Mixing an organic solution of aniline with an aqueous solution of graphene oxide containing an initiator and reacting under stirring conditions to obtain an intermediate product;

[0024] After the intermediate product is dried and heated to react, graphene rolls are obtained.

[0025] The invention mixes and reacts the organic solution of aniline and the graphene oxide aqueous solution containing the initiator to obtain the intermediate product. The present invention first dissolves aniline in the organic solution to obtain the organic solution of aniline; dissolves the initiator in the graphene oxide aqueous solution to obtain the graphene oxide aqueous solution containing the initiator; the mass concentration of the aniline in the organic solution is n, the n preferably satisfies the following conditions: 0g / L

Example Embodiment

[0035] Example 1

[0036] 10mL concentration is the n-amyl alcohol solution of 10g / L aniline, 0.1g ammonium persulfate is dissolved in the graphene oxide aqueous solution that 500mL concentration is 0.3g / L, after the above-mentioned graphene oxide aqueous solution and the n-amyl alcohol solution of aniline are mixed Stir the reaction at 1000r / min for 10 hours to obtain the product in the reaction. After repeated washing with absolute ethanol and deionized water, the product in the reaction is freeze-dried and annealed at 300°C for 5 hours to prepare graphene rolls. .

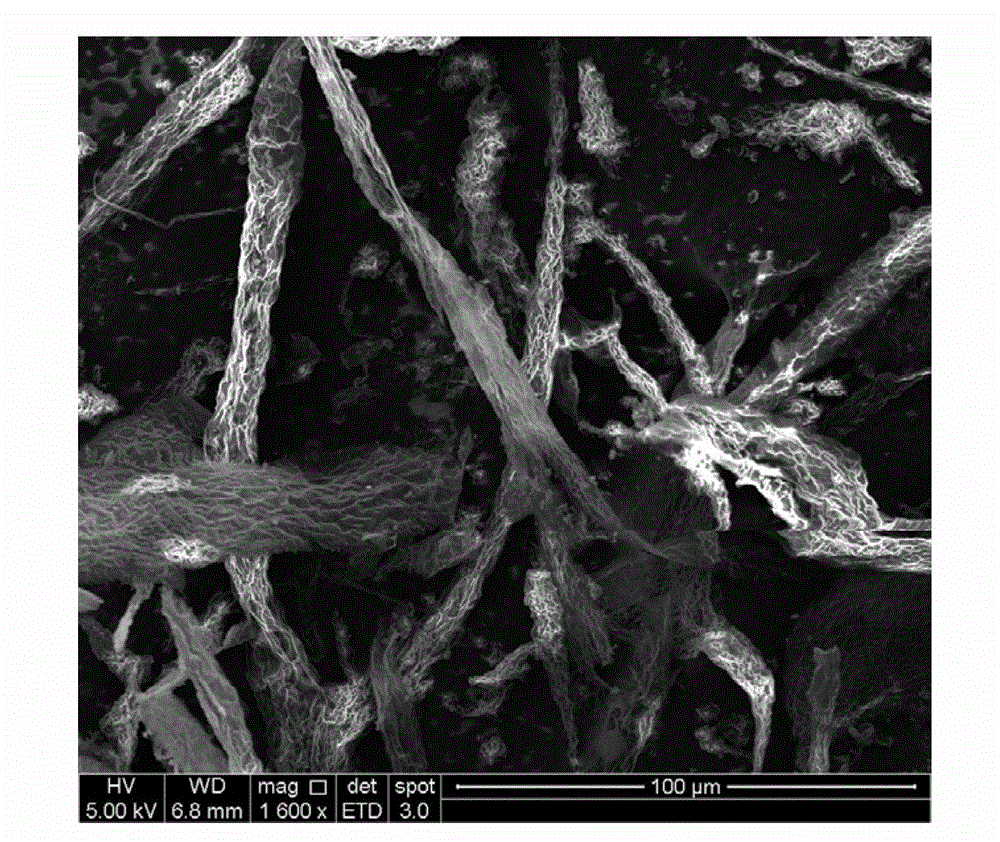

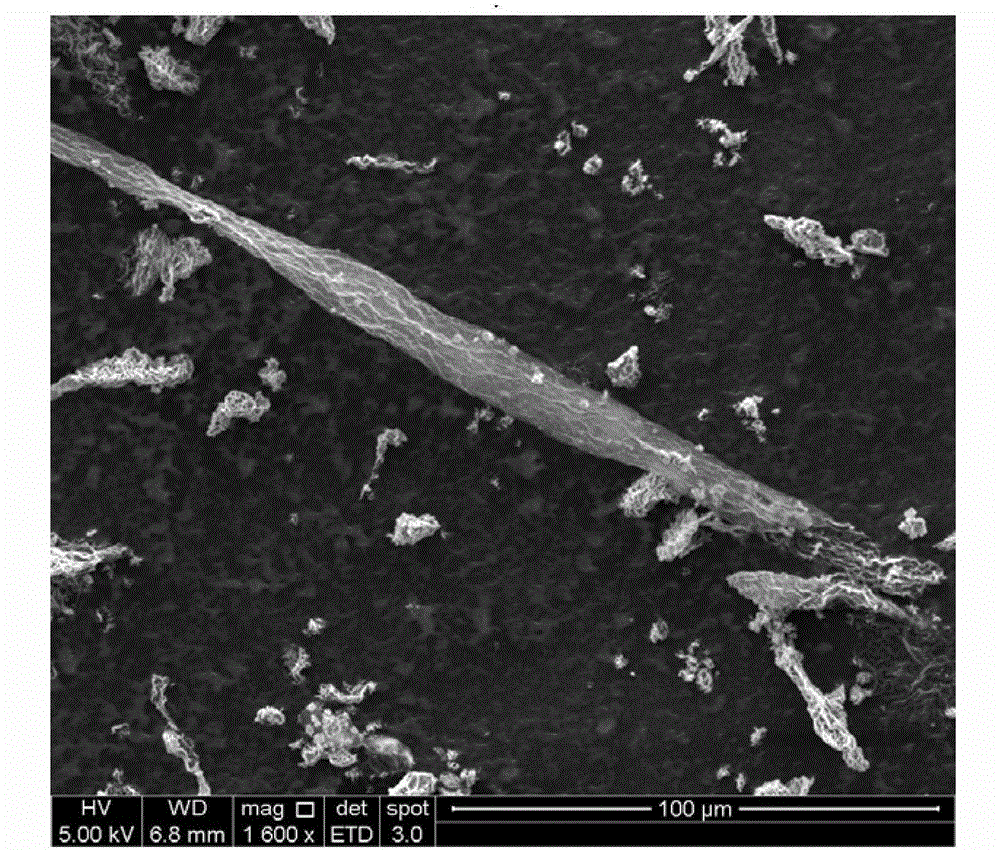

[0037] The result is as figure 1 and figure 2 as shown, figure 1 The transmission electron microscope figure of the graphene roll that is prepared for the embodiment of the present invention 1, by figure 1 It can be seen that the nitrogen-doped graphene sheet structure obtained in the present invention is complete. figure 2 It is the TEM selected area electron diffraction pattern of the graphene roll prepar...

Example Embodiment

[0038] Example 2

[0039] 10mL concentration is the n-butanol solution of 0.1g / L aniline, 0.2mg ferric chloride is dissolved in 100mL concentration and is the graphene oxide aqueous solution of 0.01g / L, after the above-mentioned graphene oxide aqueous solution is mixed with the n-amyl alcohol solution of aniline Stir the reaction at 300r / min for 24 hours to obtain the product in the reaction. After repeated washing with absolute ethanol and deionized water, the product in the reaction is freeze-dried and annealed at 1000°C for 0.5 hours to prepare graphene roll.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com