Compound antioxidant for producing emulsion-polymerized styrene butadiene rubber and application thereof

A technology for styrene-butadiene rubber and emulsion polymerization, which is applied to compound antioxidants and application fields in the production of emulsion-polymerized styrene-butadiene rubber, can solve problems such as limited application range, and achieves simple process operation, easy emulsification, and stable protection. Effect

Inactive Publication Date: 2013-03-20

RIANLON

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the anti-aging agent 555PD is a mixture of alkyl-aryl p-phenylenediamine, and the product contains amine groups. It is only suitable for emulsion polymerization of styrene-butadiene rubber that allows coloring, and its application range is not wide.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

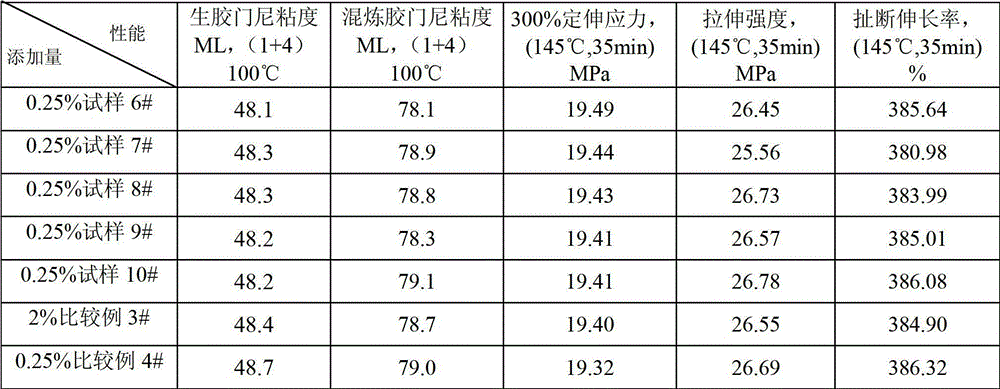

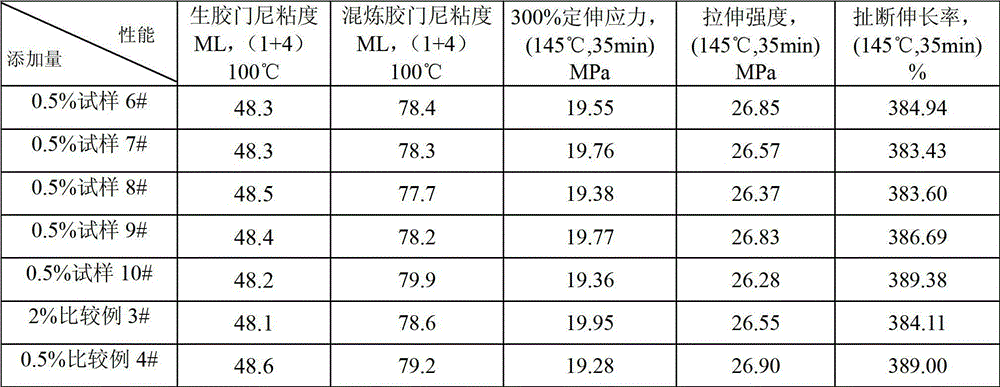

example 1

[0024] Weigh 10g of antioxidant 2-methyl-4,6-bis(octylthiomethyl)phenol and 14g of styrylphenol to make compound antioxidant 1#.

example 2

[0026] Weigh 10g of antioxidant 2-methyl-4,6-bis(octylthiomethyl)phenol and 16g of styrylphenol to make compound antioxidant 2#.

example 3

[0028] Weigh 10g of antioxidant 2-methyl-4,6-bis(octylthiomethyl)phenol and 18g of styrylphenol to make compound antioxidant 3#.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a compound antioxidant for producing emulsion-polymerized styrene butadiene rubber and an application thereof. The compound antioxidant is obtained by mixing and compounding hindered phenolic antioxidant styryl phenol and 2-methyl-4,6-di(octylthimethyl)-phenol in a proportion. New liquid antioxidant is added to the emulsion-polymerized styrene butadiene rubber after being emulsified; and the test result indicates that the antioxidant provided by the invention has remarkably improved hot-oxygen ageing resistance and long-term aging resistance in compared with a conventional antioxidant which is a complex of styryl phenol and TNPP (Trisnonylphenylphosphite), is more economical in comparison with liquid antioxidant 2-methyl-4,6-di(octylthimethyl)-phenol, does not contain TNPP and is an environment-friendly antioxidant.

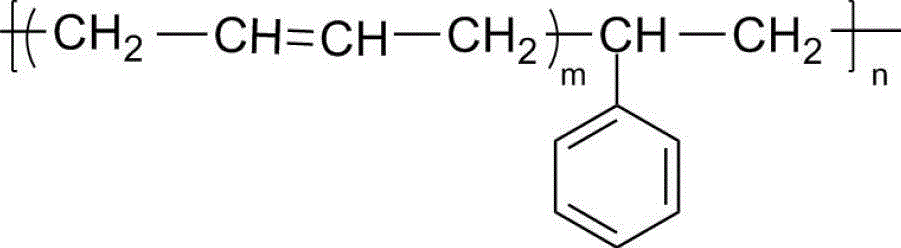

Description

technical field [0001] The present invention relates to a new antioxidant for maintaining excellent stability during the production, storage and application of emulsion polymerized styrene-butadiene rubber. The antioxidant consists of liquid sulfur-containing hindered phenolic antioxidant 2-methyl-4, 6-bis(octylthiomethyl)phenol and liquid hindered phenolic antioxidant styrenated phenol in a preferred ratio of 1.0:2.2 (weight ratio), especially 1.0:1.6-2.0 (weight ratio), for emulsion polymerization In the production of styrene-butadiene rubber, it can excellently protect the produced emulsion polymerized styrene-butadiene rubber to maintain excellent appearance color and application performance during production, storage, transportation and use. Background technique [0002] Styrene-butadiene rubber is the largest general-purpose synthetic rubber variety, and it is also one of the earliest rubbers to realize industrial production. It is a random copolymer of butadiene and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L9/06C08K5/375C08K5/13

Inventor 安平汤翠祥范小鹏孙春光李海平

Owner RIANLON

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com