Etching solution composition for metal oxide layer containing gallium

An oxide layer, etching solution technology, applied in surface etching compositions, chemical instruments and methods, electrical components, etc., can solve problems such as difficulty in reducing the number of processes, achieve economic advantages, simplify etching processes, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0083] For a mixture with a total weight percentage of 100%, 10% by weight of ammonium persulfate (APS), 5% by weight of nitric acid (HNO 3 ), 5% by weight sulfuric acid (H 2 SO 4 ) and the remaining content of water were mixed together to prepare 180 kg of an etching solution composition.

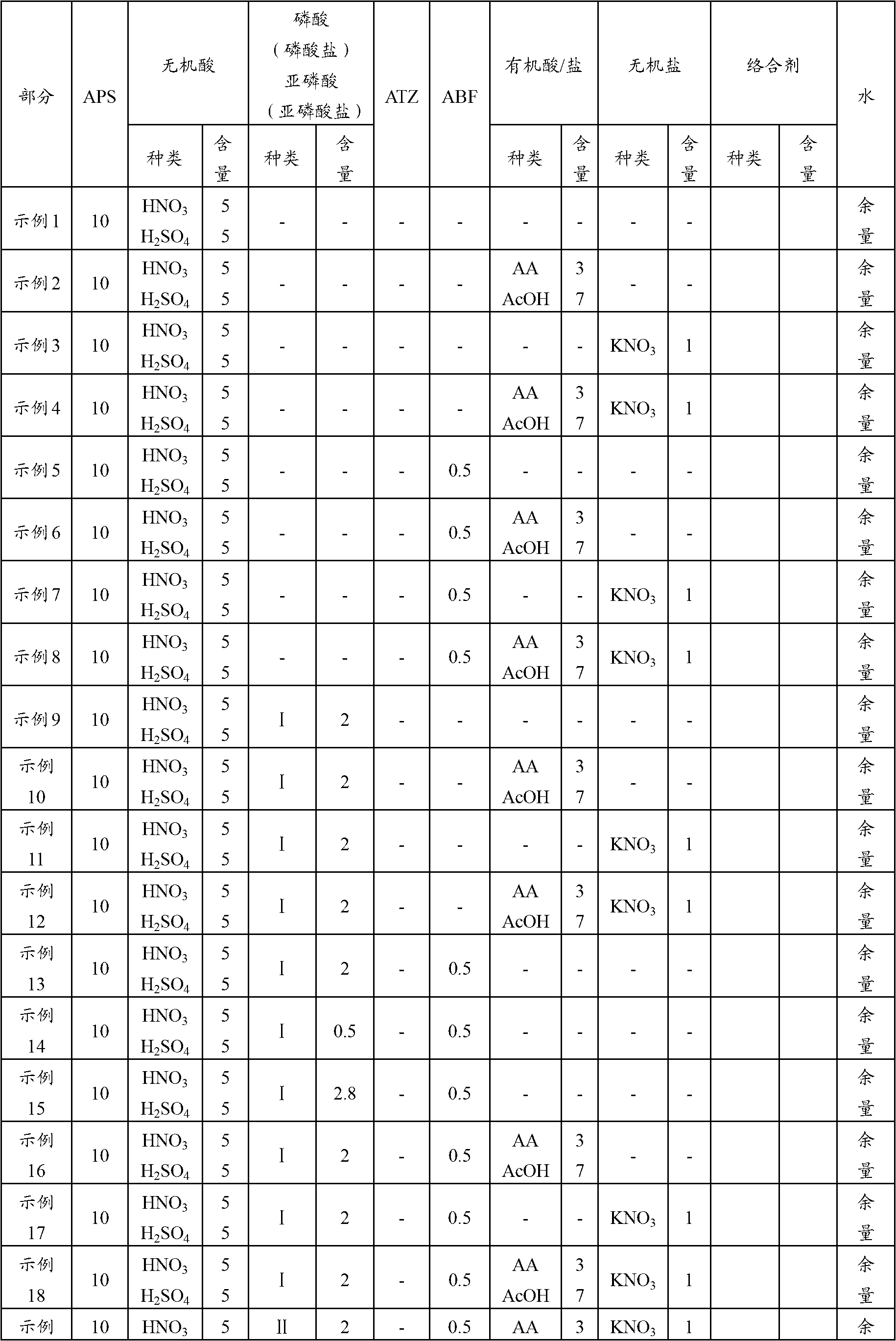

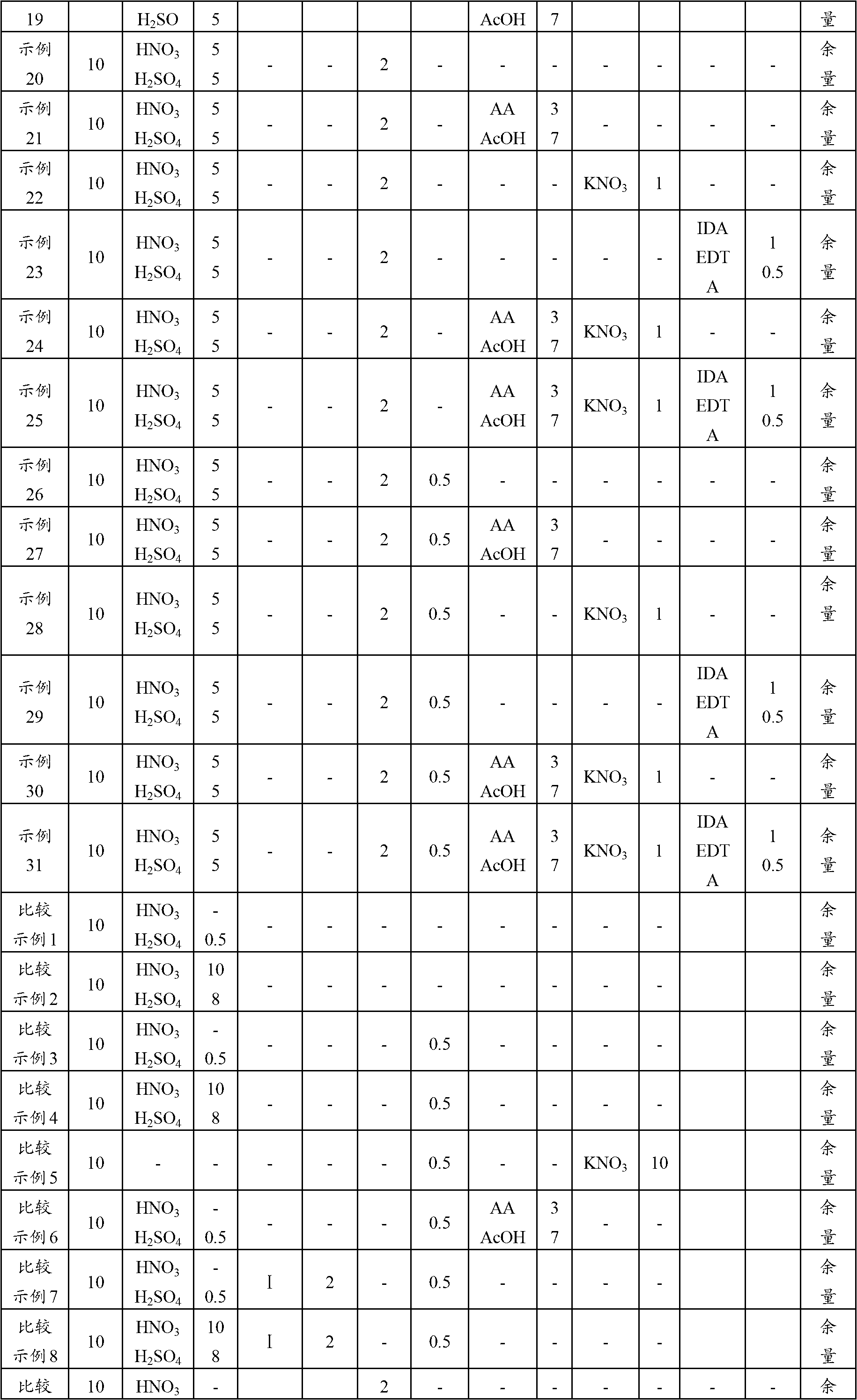

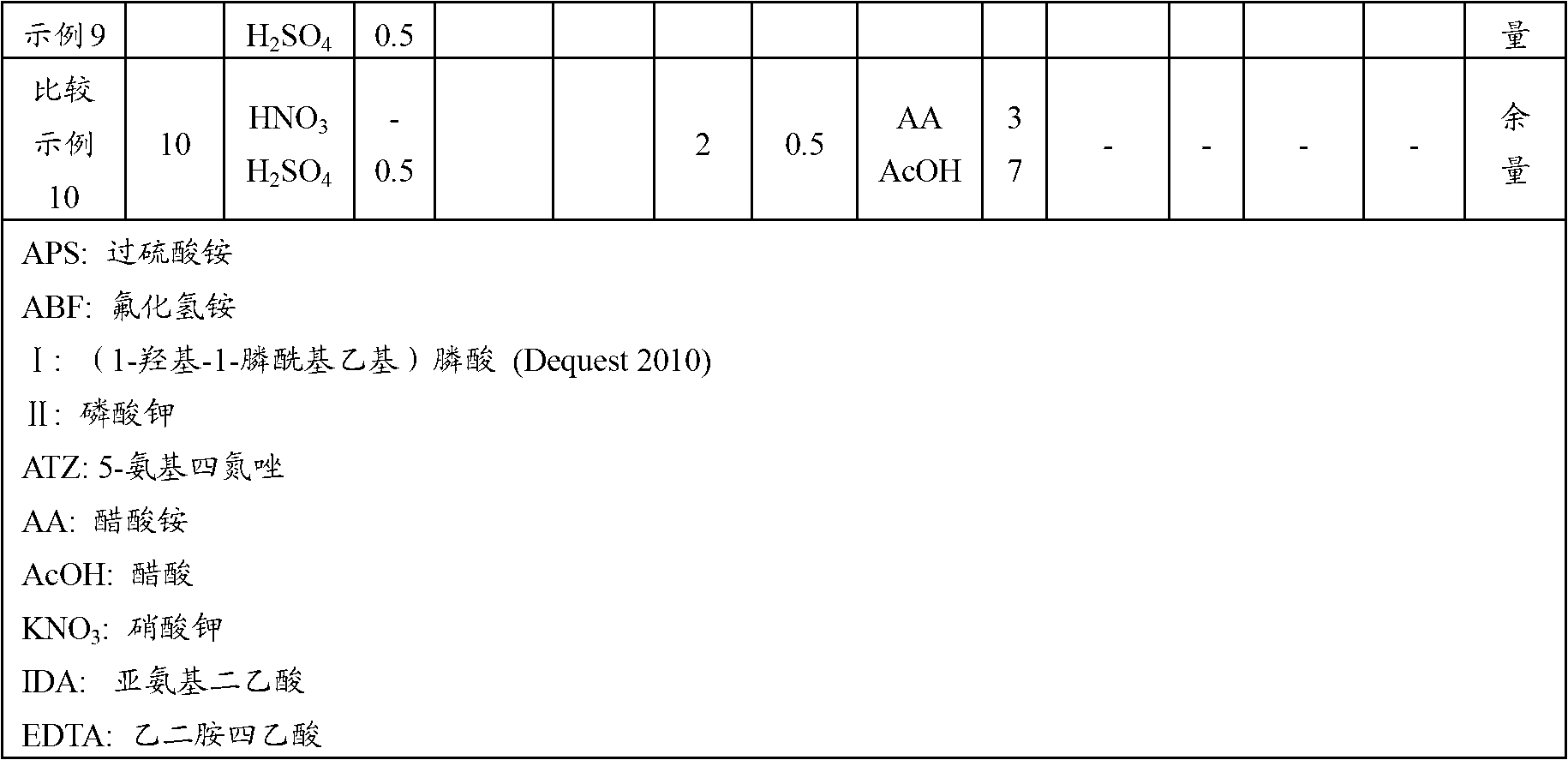

[0084] Example 2~Example 31, Comparative Example 1~Comparative Example 10

[0085] The above process described in Example 1 was repeated except for using the individual ingredients and their amounts listed in Table 1 below. The content is expressed in percent by weight here.

[0086] Table 1

[0087]

[0088]

[0089]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com