Additive for improving water resistance of methanol gasoline

A technology for methanol gasoline and additives is applied in the field of methanol gasoline additives for vehicles and additives for improving the water resistance of methanol gasoline, which can solve the problems of high cost, large amount of additives, and insignificant effects in high-humidity areas, and achieves low production costs. , The effect of improving the water resistance and improving the water phase separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

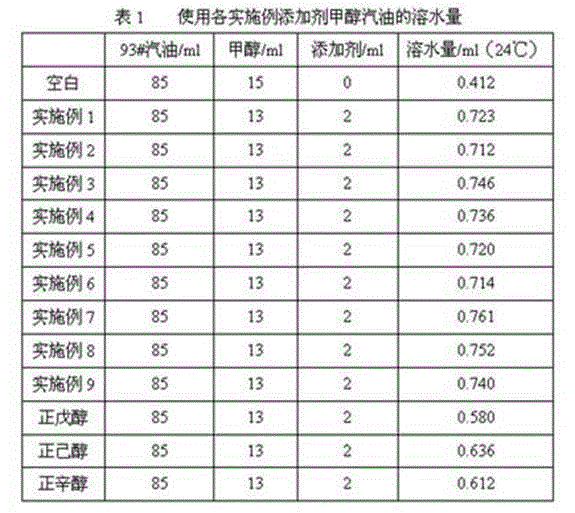

Examples

Embodiment 1

[0017] Each 100Kg additive contains: n-propanol 2.35Kg, n-butanol 11.75Kg, n-pentanol 11.75Kg, isobutanol 21.15Kg, isobutenylamide isoheptyl ester 23Kg, Tween-80 9Kg, AEO-3 12Kg, OP -4 9Kg.

Embodiment 2

[0019] Each 100Kg additive contains: n-butanol 27.5Kg, isoamyl alcohol 2.5Kg, isobutanol 20Kg, isobutenylamide isoheptyl ester 20Kg, Tween-80 7.5Kg, AEO-7 13.5Kg, OP-7 9Kg.

Embodiment 3

[0021] Each 100Kg of additives contains: isopropanol 4.3Kg, n-butanol 4.3Kg, n-pentanol 32.25Kg, isoamyl alcohol 2.15Kg, isobutenylamide isoheptyl ester 30Kg, Tween-80 8.1Kg, AEO-3 10.8Kg , OP-7 8.1Kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com