Method for preparing ultra-soft high-elastic polyurethane leather

A synthetic leather and polyurethane technology, applied in polyurea/polyurethane coatings, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of hard hand feeling, poor durability, and poor fullness, and achieve good softness and durability Excellent performance, natural pattern effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

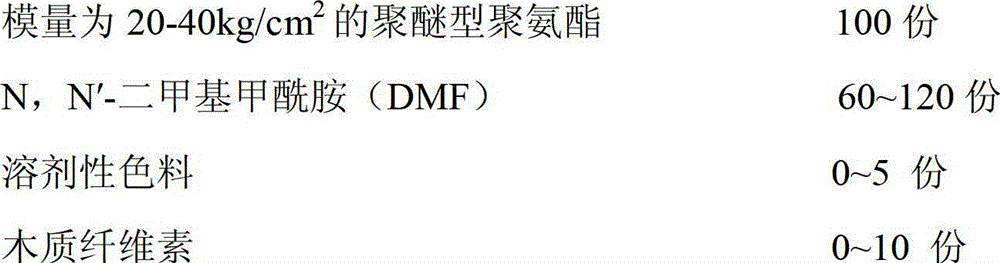

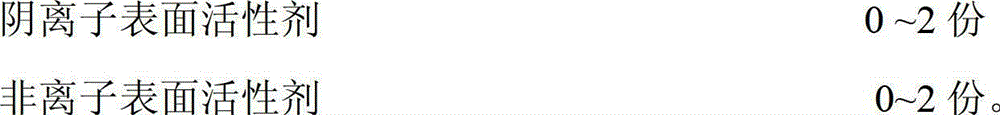

Method used

Image

Examples

Embodiment Construction

[0019] Manufacturers and trade marks of raw materials used in the embodiments of the present invention are as follows:

[0020] Solvent-based colorant: Zhejiang Deep Blue Textile Technology Co., Ltd., BLPN560

[0021] Anionic surfactant: Jiande Shunfa Chemical Co., Ltd., SF-7

[0022] Nonionic surfactant: Shanghai Rishen Chemical Co., Ltd., S-11

[0023] Stripping aid: BYK, BYK-9565

[0024] Water-based softener: Hefei Lankai Chemical Co., Ltd., LK-136

[0025] Slip agent: Jinling Auxiliary Factory, Jinhu County, HY-905

[0026] Polyether polyurethane: Hefei Amway Polyurethane New Material Co., Ltd., SW-5015RH

[0027] Polyether polyurethane: Hefei Amway Polyurethane New Material Co., Ltd., SW-4015

[0028] Polyurethane resin: Hefei Amway Polyurethane New Material Co., Ltd., LT-80.

[0029] The preparation method of supersoft high elastic polyurethane synthetic leather of the present invention operates as follows:

[0030] a. Choose 180g / m 2 Double-sided knitted fleece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com