Chopped glass fiber core material harmless to human body and preparation method thereof

A technology of glass fiber and glass fiber mat, applied in the field of chopped glass fiber core material and its preparation, can solve the problems of unsatisfactory and unable to export to the EU, and achieve the effect of uniform fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A chopped strand glass fiber core material harmless to the human body, characterized in that the core material is composed of multi-layer chopped strand glass fiber mats, wherein the chopped strand glass fiber has a diameter of 8 μm and a length of 20 mm. The thickness of each layer of glass fiber felt is 1 mm, and the number of layers of glass fiber felt is 50 layers.

[0032] The present invention also provides a method for preparing a chopped strand glass fiber core material harmless to human body, which is characterized in that it comprises the following steps:

[0033] (1) Take 10kg of chopped glass fiber, the fiber diameter is 8μm, and the length is 20mm;

[0034] (2) Put the above-mentioned chopped glass fiber into the beating tank, and add water, thickener and dispersant, after beating, the concentration of the slurry is 0.5%, and send it into the slurry storage tank 10;

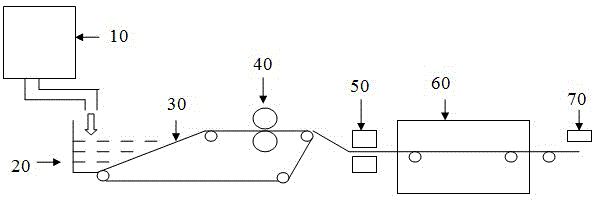

[0035] (3) Send the above-mentioned slurry into the head box 20, form a continuous glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com