Horizontal hole drilling machine

A technology for horizontal drilling and drilling rigs, which is applied in the direction of rotary drilling rigs, earthwork drilling, drilling equipment, etc. It can solve the problems of adapting to less formations, digging large pits, and large volumes, and achieve the effect of small size and powerful power of the main engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

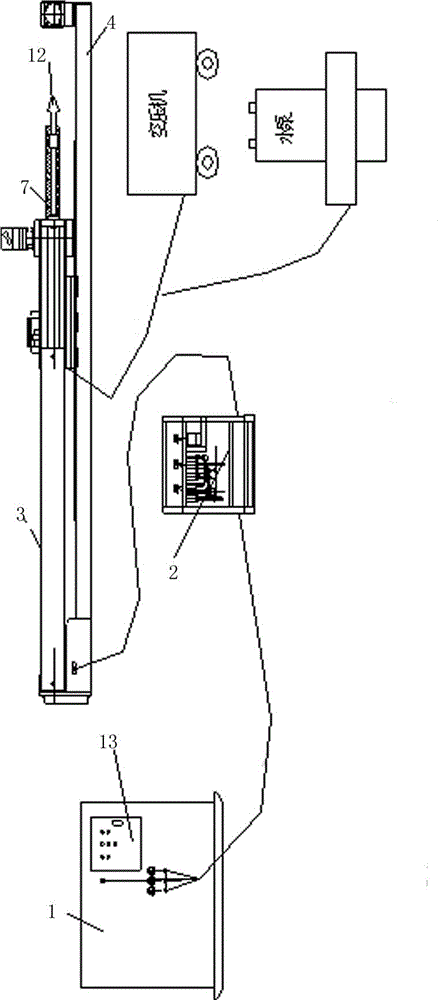

[0046] root attached Figure 1-Figure 5 As shown, a horizontal hole drilling machine includes three separate module parts: pumping station part 1, console part 2, host part 3;

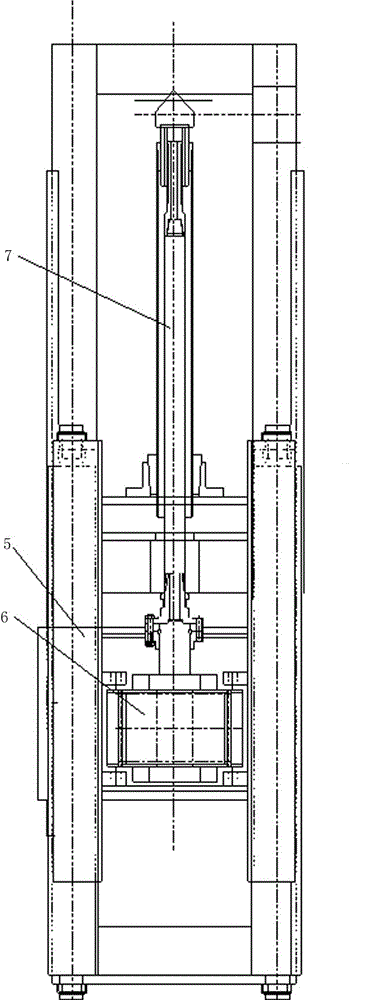

[0047] The main engine part 3 includes: a frame 4, a propulsion cylinder 5 is arranged on both sides of the frame 4, a power head 6 is arranged in the middle of the propulsion cylinder 5, and a fixed base frame is used to connect the propulsion cylinder 5 and the power head 6 into a whole , to realize the synchronous forward and backward movement of the power head and the oil cylinder, and the connector of the power head 6 is connected with the drilling tool 7 . The hydraulic motor of the power head 6 is connected with the valve assembly of the console through oil pipes. The propulsion oil cylinder 5 is connected with the valve assembly of the console through the oil pipe.

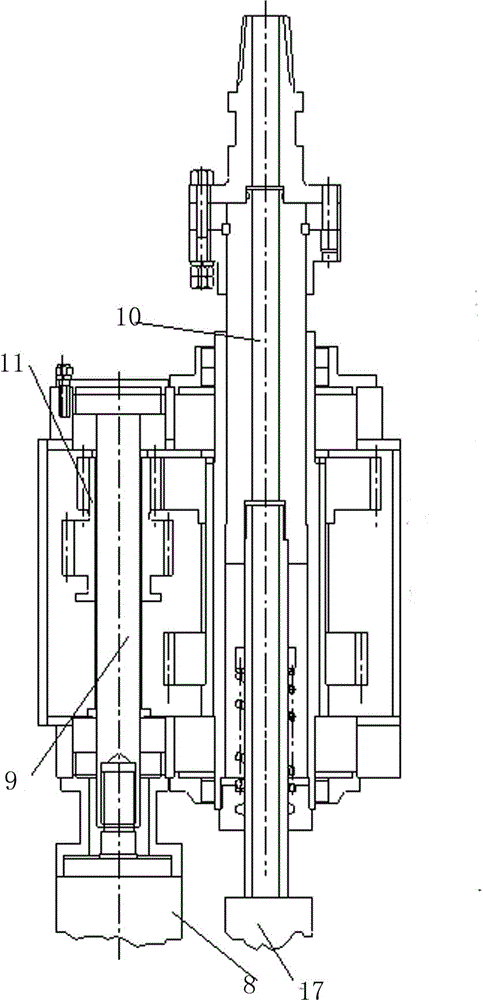

[0048] The power head 6 includes: a hydraulic motor 7 is connected to the input shaft 8 of the gearbox, and the gear on the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com