Adherence air device for preventing high-temperature corrosion of water cooling wall of refuse burning boiler

A technology of waste incineration and high-temperature corrosion, which is applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as inevitability and impact, and achieve the effects of long transportation distance, obvious benefits, and reduced flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in further detail below, but the embodiments of the present invention are not limited thereto.

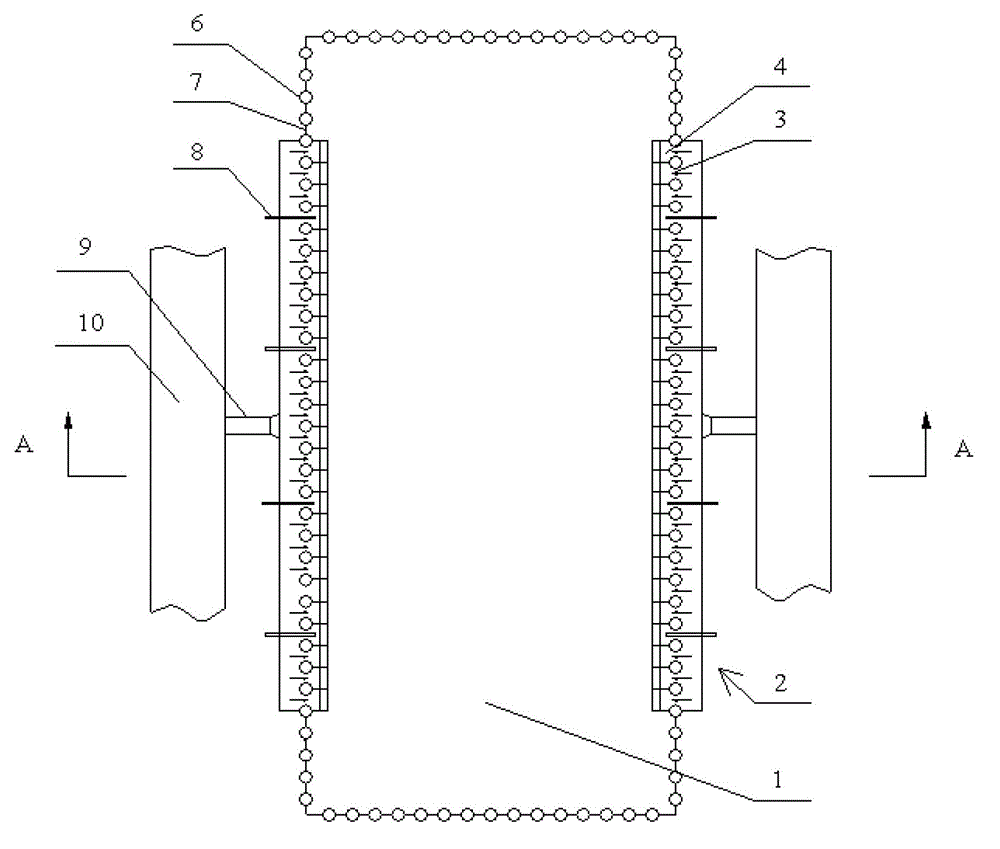

[0024] Such as figure 1 As shown, the present invention is used to prevent the high-temperature corrosion of the water wall of the waste incineration boiler.

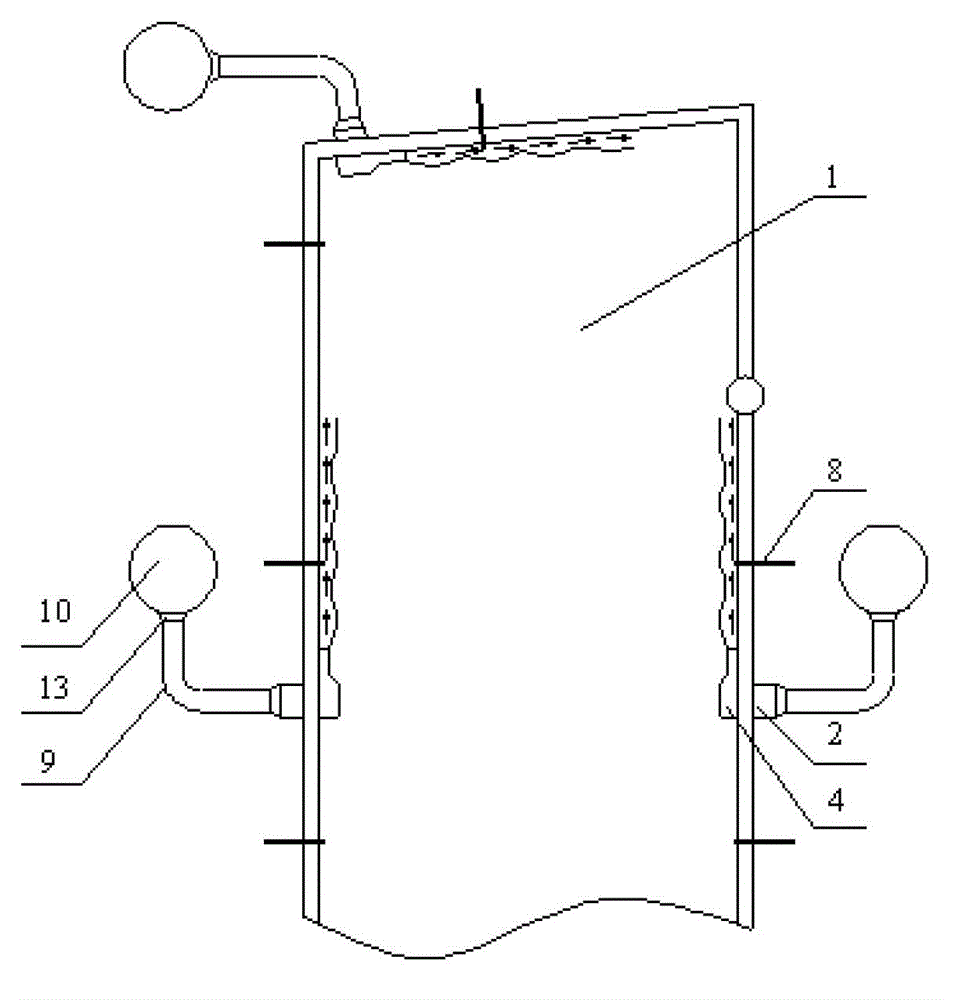

[0025] Such as figure 2 As shown, the wall-attached wind device comprises a wall-attached wind box 2 and a wall-attached wind nozzle 4, one end of the wall-attached wind box 2 is connected with the wall-attached wind nozzle 4, and the other end of the wall-attached wind box 2 Be connected with air duct 9;

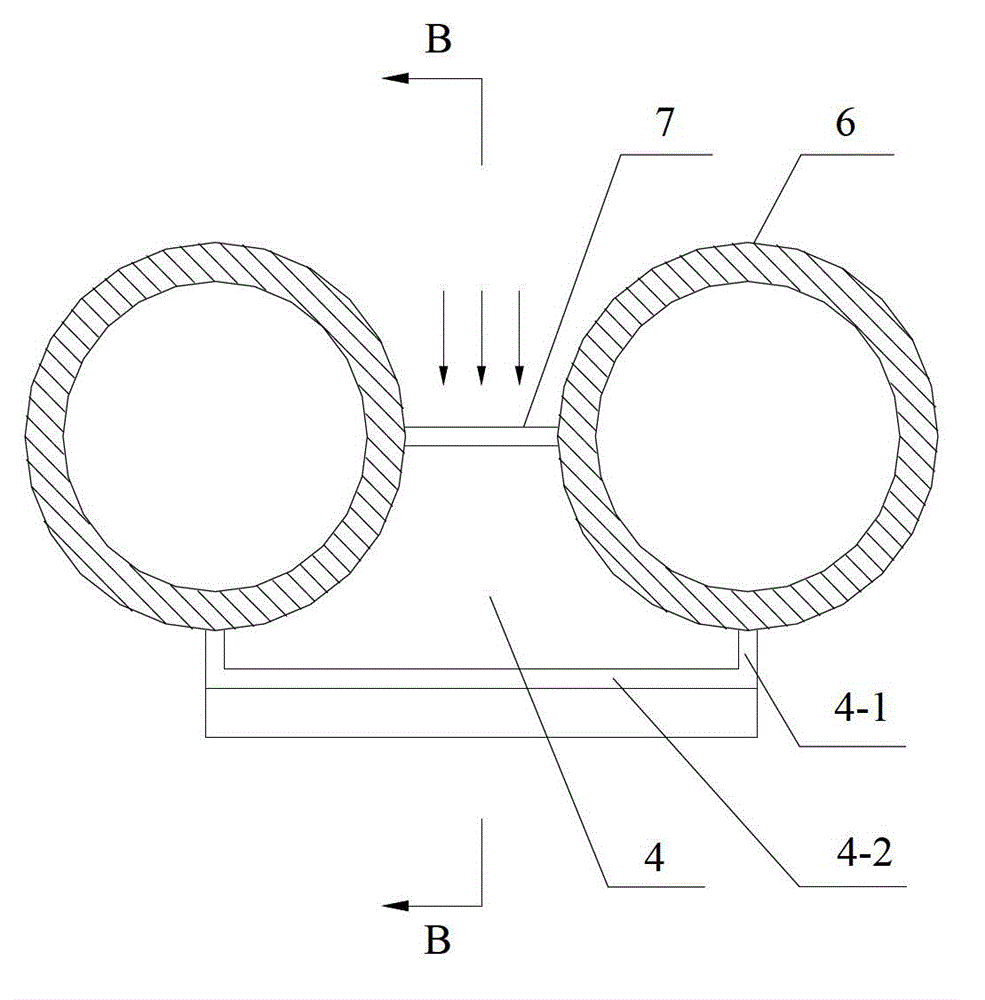

[0026] Such as image 3 , Figure 4 As shown, the wall-attached wind nozzle 4 includes nozzle fins 4-1, front baffles 4-2, bottom baffles 4-3, water wall tubes 6, water wall fins 7; front baffles 4- 2 Consists of inlet baffle 4-2-1, tapered baffle 4-2-2, and outlet baffle 4-2-3, and a purge slit 4-2 is opened on the outlet baffle 4-2-3 -4; r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com