On-line examination system and method for steel pipe

A detection system, a technology for steel pipes, applied in measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of low production efficiency, high labor intensity, low accuracy, etc., and achieve high production efficiency, reduced labor intensity, accurate high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

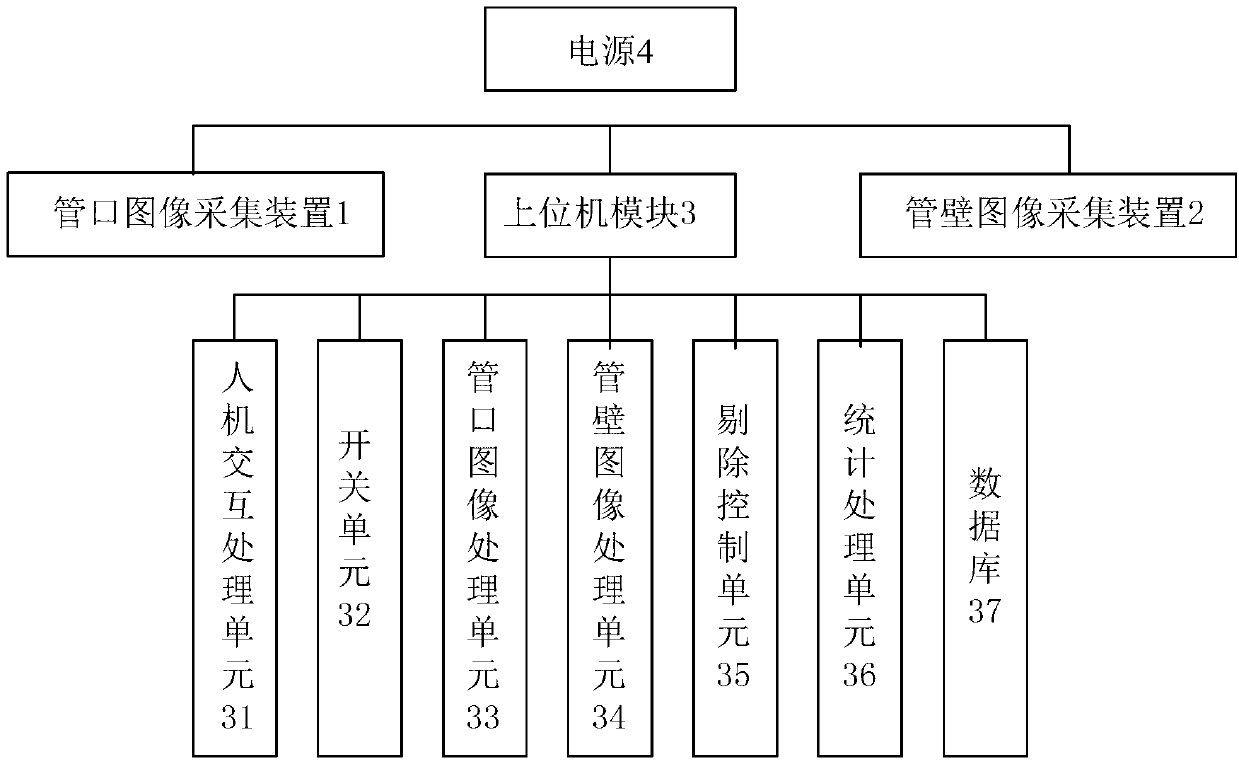

[0028] An online inspection system for steel pipes, comprising: a nozzle image acquisition device 1, a pipe wall image acquisition device 2, a host computer module 3 and a power supply 4, the nozzle image acquisition device 1 and the pipe wall image acquisition device 2 adopting CCD color cameras or CMOS Color cameras, both of which are connected to the host computer module 3, are used to collect the steel pipe nozzle image and pipe wall image in real time and send them to the host computer module 3; the host computer module 3 is used to analyze the collected images and eliminate unqualified For steel pipes, the pass rate of steel pipe nozzle and pipe wall parameters is counted; the power supply 4 is respectively connected to the nozzle image acquisition device 1, the pipe wall image acquisition device 2 and the host computer module 3, and is used for the nozzle image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com