Production line reporting system

A notification system and production line technology, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as increased production costs, erroneous modification or loss of tracking information, and complicated production line work, to improve yield and accuracy. Sex and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

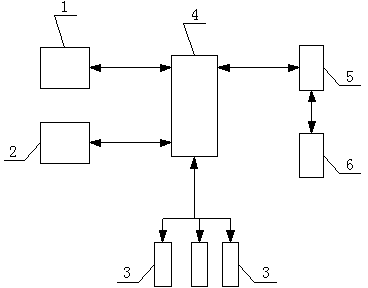

[0024] Such as figure 1 As shown, a production line notification system of the present invention, through the information recording client 1, the user can add and / or update the latest progress of the record, and each time the information recording client 1 is operated, the operation information will be recorded to facilitate subsequent View the historical information and progress of each item, and each client can query various production-related situations through the notification system to make timely arrangements and adjustments for the work; information recording client 1 transmits data information to the middle layer The server 4, such as HP Pro 3000 MT, stores the processed information in the storage database 5, such as HP RP8640, and regularly backs up the processed information data to the backup database 6, such as HP RP8640. For example: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com