Self-adaption temperature compensating capacitor

A temperature compensation, capacitor technology, applied in the field of capacitors, can solve problems such as complicated problems, and achieve the effect of good electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

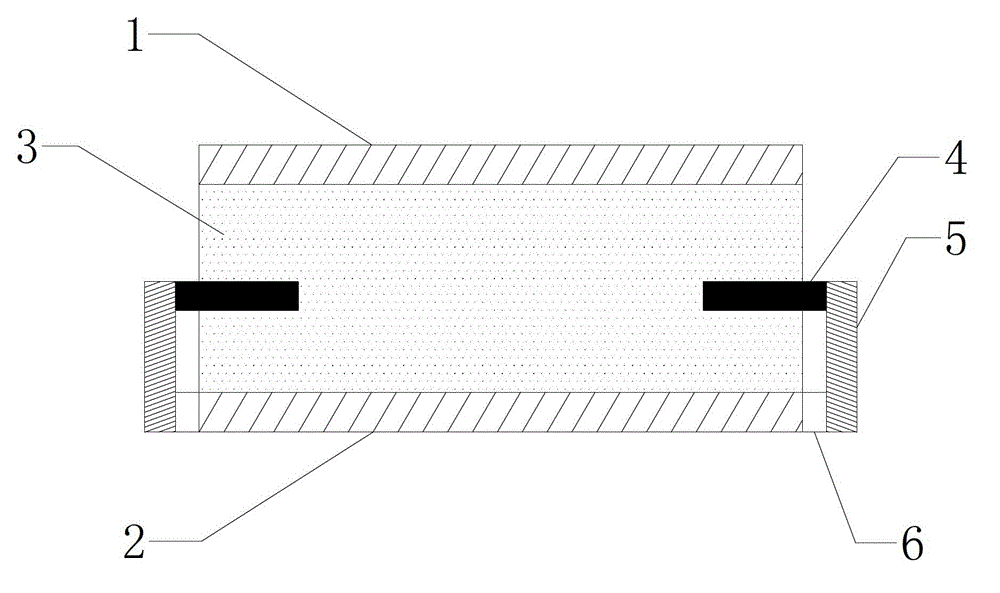

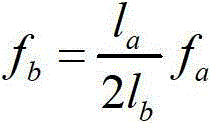

[0019] Such as figure 1 As shown, an adaptive temperature compensation capacitor includes a first plate 1, a second plate 2 and a dielectric 3, and is characterized in that: the capacitor also includes a ground conductor 5, a compensation conductor 4 and an insulating washer 6, the The first pole plate 1, the second pole plate 2 and the grounding conductor 5 adopt metal materials with the same thermal expansion coefficient, and one end of the compensation conductor 4 extends between the first pole plate 1 and the second pole plate 2 to shield the first pole plate The part between 1 and the second pole plate 2 is directly opposite, and the other end is connected to the ground conductor 5; the ground conductor 5 is insulated from the second pole plate 2 through the insulating gasket 6, and the thermal expansion coefficient of the compensation conductor 4 greater than the coefficient of thermal expansion of the first pole plate 1 and the second pole plate 2 . The capacitor is a ...

Embodiment 2

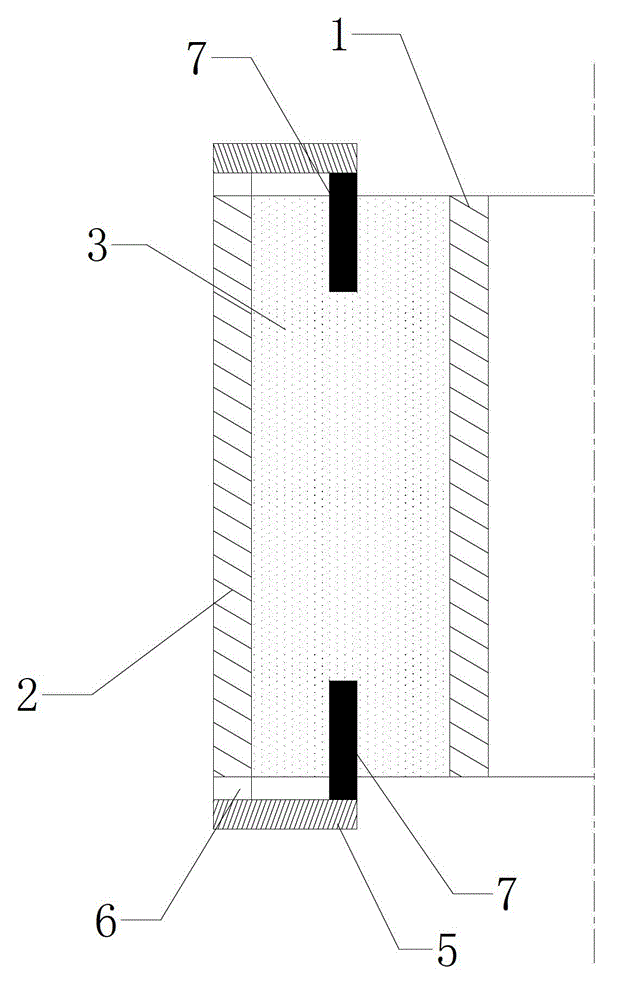

[0023] The principle of the capacitor of this embodiment is the same as that of Embodiment 1, except that the capacitor is a coaxial cylindrical capacitor, and the first pole plate 1 and the second pole plate 2 are both cylindrical and coaxially arranged, so The compensation conductor 4 includes two sections of cylindrical half-compensation conductors 7 , both of which are connected to the ground conductor 5 . In this way, the deformation of the first pole plate 1 and the second pole plate 2 changes not only in the axial direction but also in the radial direction, so that the overall capacitance value of this coaxial cylindrical capacitor increases, and two semi-compensating conductors are added 7. The coefficient of thermal expansion of the two semi-compensating conductors 7 is greater than that of the first pole plate 1 and the second pole plate 2. In this way, during thermal expansion, the facing area of the shield is increased, thereby ensuring the capacitance value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com