Sectional type switch reluctance motor

A switched reluctance motor, segmented technology, applied in the field of magnetic circuit components, can solve problems such as coupling or mutual inductance interference of each segment, unstable motor operation, etc., and achieve the goal of improving reliability, increasing product reliability and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

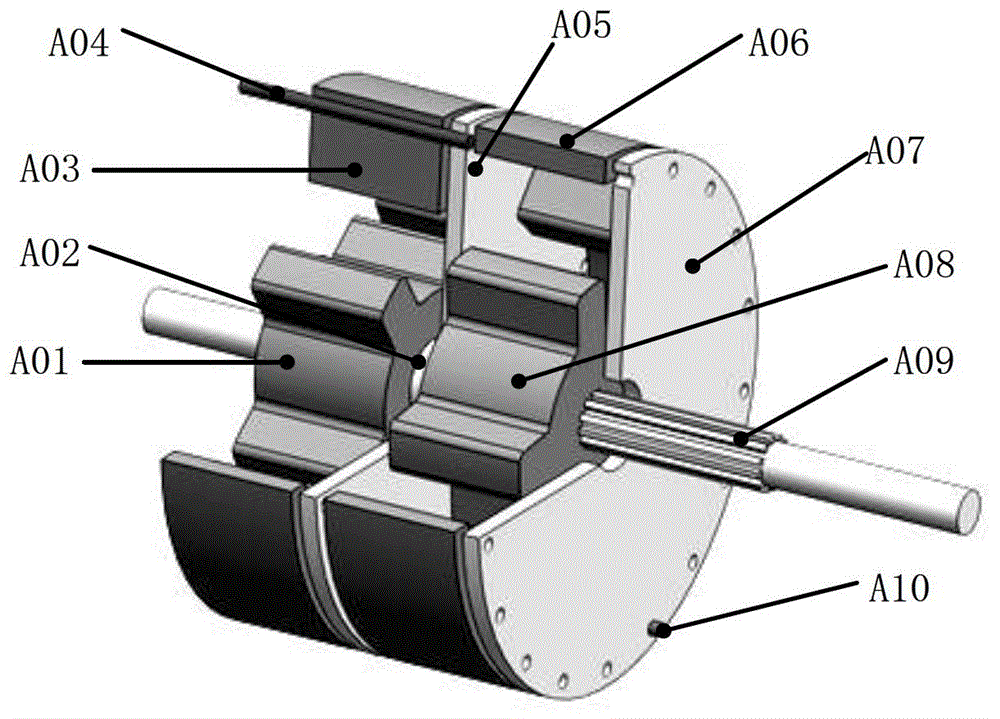

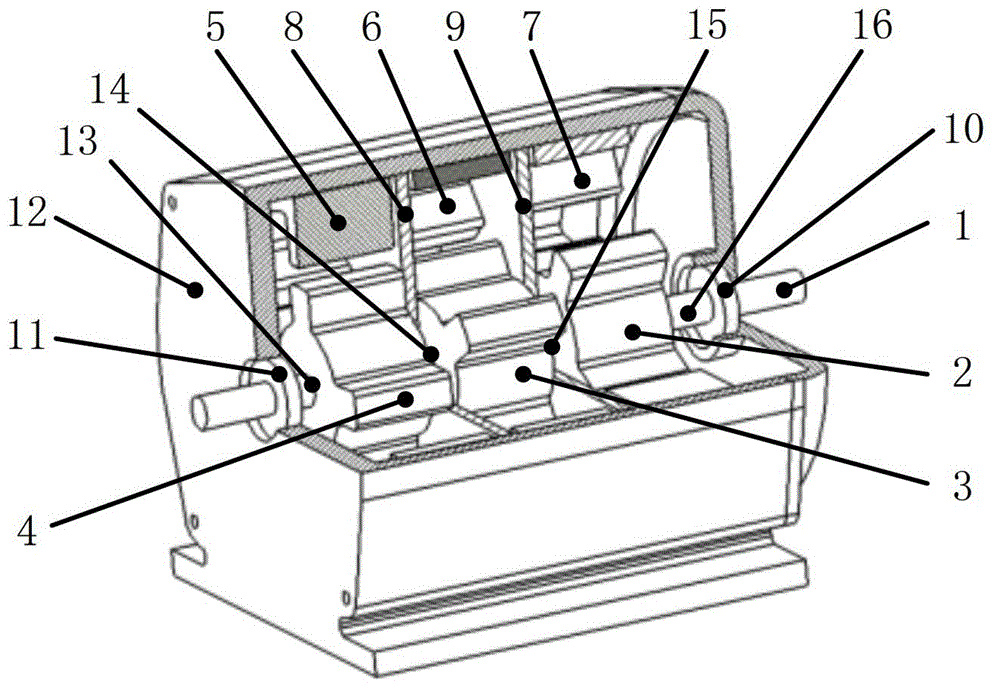

[0039] like image 3 As shown, this embodiment is a three-segment three-phase 6 / 4 type segmented switched reluctance motor, including: a main shaft 1, three-segment stators 2, 3, 4, and three-segment rotors 5, 6, 7 arranged on the main shaft 1 , and shaft sleeves 13, 14, 15, 16, wherein: two magnetic isolation plates 8, 9 are respectively provided between the first to third stators 2, 3, 4 and the first to third rotors 5, 6, 7 , The first to third rotors 5, 6, 7 are axially positioned by four sleeves 14, 15, 16, 17. The first to third stators 2, 3, 4 and the first to third rotors 5, 6, 7 are uniformly distributed around the axial direction of 360°, that is, the difference between the first to third stators 2, 3, 4 is 20°, The difference between the first to the third rotors 5, 6, 7 is 30°.

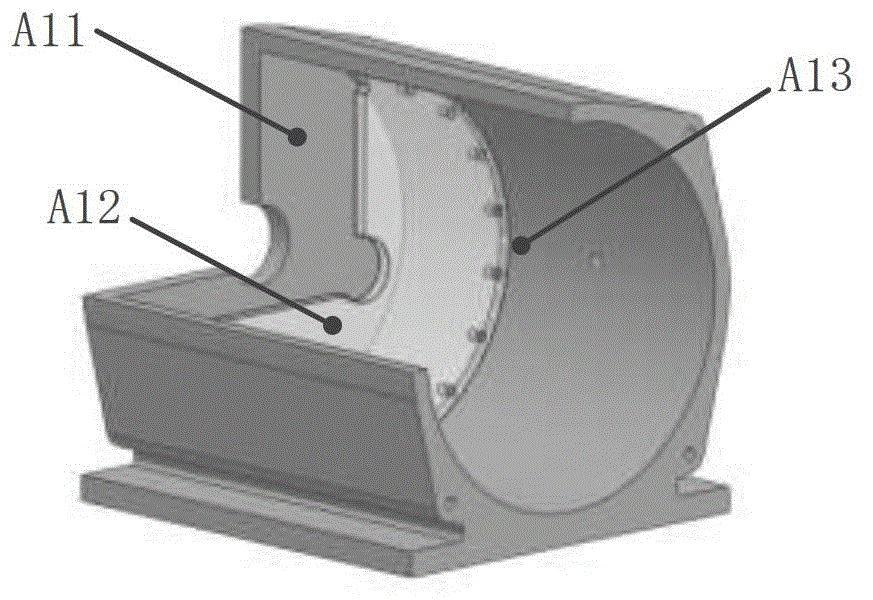

[0040] The main shaft 1 is arranged on a motor housing 12 by a rear end bearing 10 and a front end bearing 11 .

[0041] The first to third stators 2 , 3 , 4 are respectively fixed on t...

Embodiment 2

[0054] like Figure 8 As shown, the present embodiment is a four-stage 6 / 4 type segmented switched reluctance motor, including: a main shaft 601, four-stage stators 602, 603, 604, 605, four-stage rotors 606, 607, 608, 609, and shaft sleeves 610, 611, 612, 613, 614, wherein: each section of stator 602, 603, 604, 605 and each section of rotor 606, 607, 608, 609 are respectively provided with magnetic isolation plates 615, 616, 617, the rotors 606, 607, 608, 609 of each section are axially positioned by the shaft sleeves 610, 611, 612, 613, 614. Each section of stator 602, 603, 604, 605 and rotor 606, 607, 608, 609 are uniformly distributed around the axial direction of 360°, that is, the difference between each section of stator 602, 603, 604, 605 is 15°, and each section of rotor 606, The difference between 607, 608, and 609 is 22.5°.

[0055] The main shaft 601 is a spline shaft, and is arranged on the motor housing 620 by the rear end bearing 618 and the front end bearing 6...

Embodiment 3

[0058] like Figure 10 As shown, this embodiment is a two-stage 8 / 6 type segmented switched reluctance motor, including: a main shaft 713, two-stage stators 708, 709, two-stage rotors 710, 711 arranged on the main shaft 713, and a shaft sleeve 704 , 705, 706, wherein: a magnetic isolation plate 712 is provided between the stators 708, 709 and the rotors 710, 711, and the rotors 710, 711 are axially positioned by the sleeves 704, 705, 706. The phase difference between the stators 708, 709 is 22.5°, and the phase difference between the rotors 710, 711 is 30°.

[0059] The main shaft 713 is a spline shaft, and the rear end bearing 704 and the front end bearing 703 are arranged on the motor housing 701, the magnetic isolation plate 712 is fixed on the motor housing 713 by tightening screws, and the stator 708 is fixed by bolts 707 On the motor housing 701 and the magnetic isolation plate 712 , the side of the stator 709 is fixed on the magnetic isolation plate 712 and the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com