Descaling apparatus

A shell and high-pressure fluid technology, which is applied in the feeding device of abrasive materials, manufacturing tools, metal rolling, etc., can solve the problems of uneven surface roughness of steel plates, ineffective rust removal, high unit price of stainless steel beads, etc. Rust efficiency, size reduction, and surface quality improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

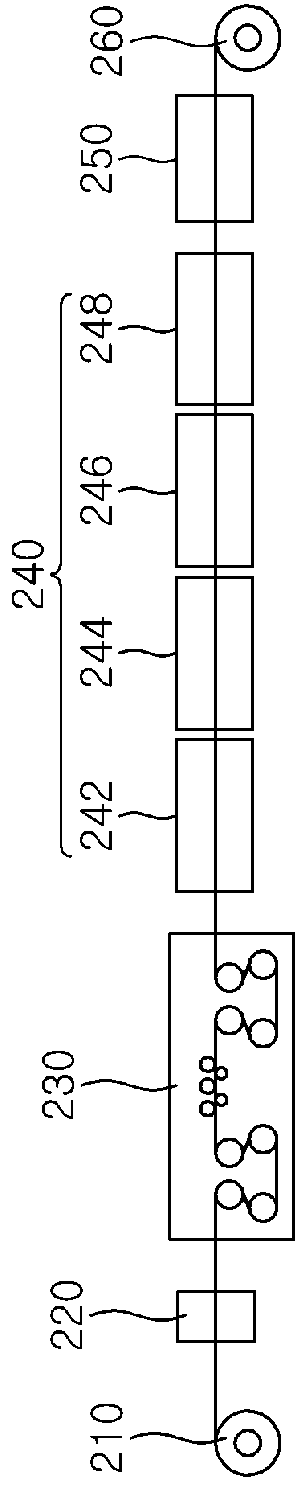

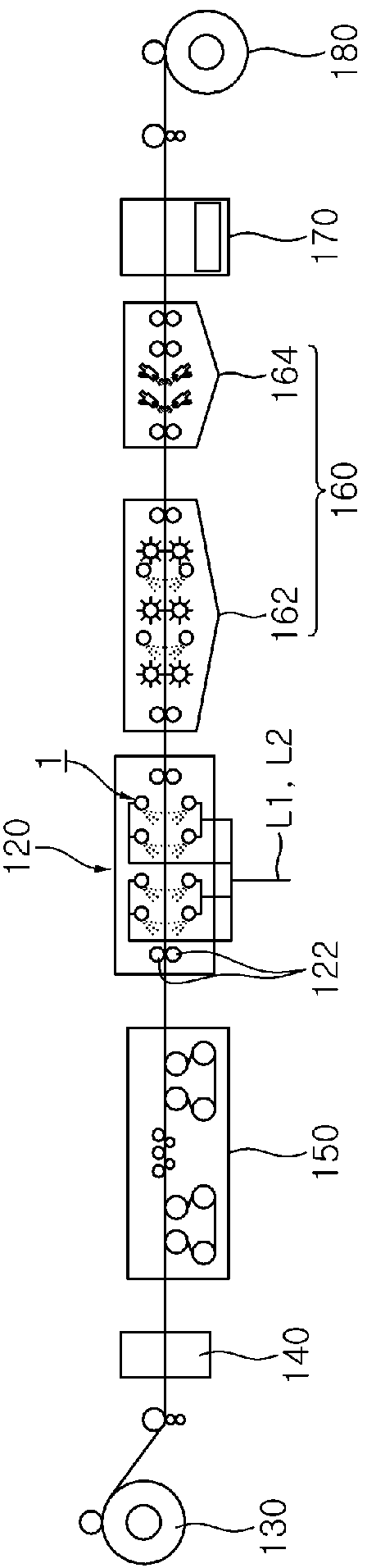

[0163] When the steel plate continues to pass under the conditions of Table 3 below, based on figure 2 The descaling treatment was performed on a low-carbon hot-rolled steel plate (2.0 mm thick x 1200 mm wide) at a line speed of 50 mpm using the process described in . As a result, the level of residual rust was less than 1%, similar to the level of residual rust of the hot-rolled steel sheet through the existing pickling treatment, the average surface roughness of the steel sheet was 1.2 μm, and the glossiness of the steel sheet surface was also excellent.

[0164] [table 3]

[0165]

Embodiment 2)

[0167] Under the conditions of Table 4 below, based on figure 2 The process described in the descaling treatment is performed on a high-strength hot-rolled steel plate (thickness 4.0 mm × width 1200 mm) at an operating line speed of 50 mpm, the hot-rolled high-strength steel plate contains 0.1% carbon, 1.2% silicon and 1.2% manganese. As a result, the level of residual rust was less than 2%, similar to the level of residual rust of the hot-rolled steel sheet through the existing pickling treatment, the average surface roughness of the steel sheet was 1.5 μm, and the glossiness of the steel sheet surface was excellent, And reduce surface defects caused by red rust.

[0168] [Table 4]

[0169]

Embodiment 3)

[0171] When the steel plate continues to pass under the conditions of Table 5 below, based on figure 2 The descaling treatment was performed on a low-carbon hot-rolled steel plate (2.3 mm thick x 1000 mm wide) at a line speed of 50 mpm using the process described in . As a result, the level of residual rust was less than 1%, similar to that of a hot-rolled steel sheet treated by conventional pickling, the average surface roughness of the steel sheet was 1.5 μm, and the glossiness of the steel sheet surface was excellent.

[0172] [table 5]

[0173]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com